Silicone gel and preparation method thereof

An organosilicon and gel technology, applied in the field of organosilicon gel and its preparation, can solve problems such as fracture, influence on the light transmittance of the gel, influence on the light transmittance of the gel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

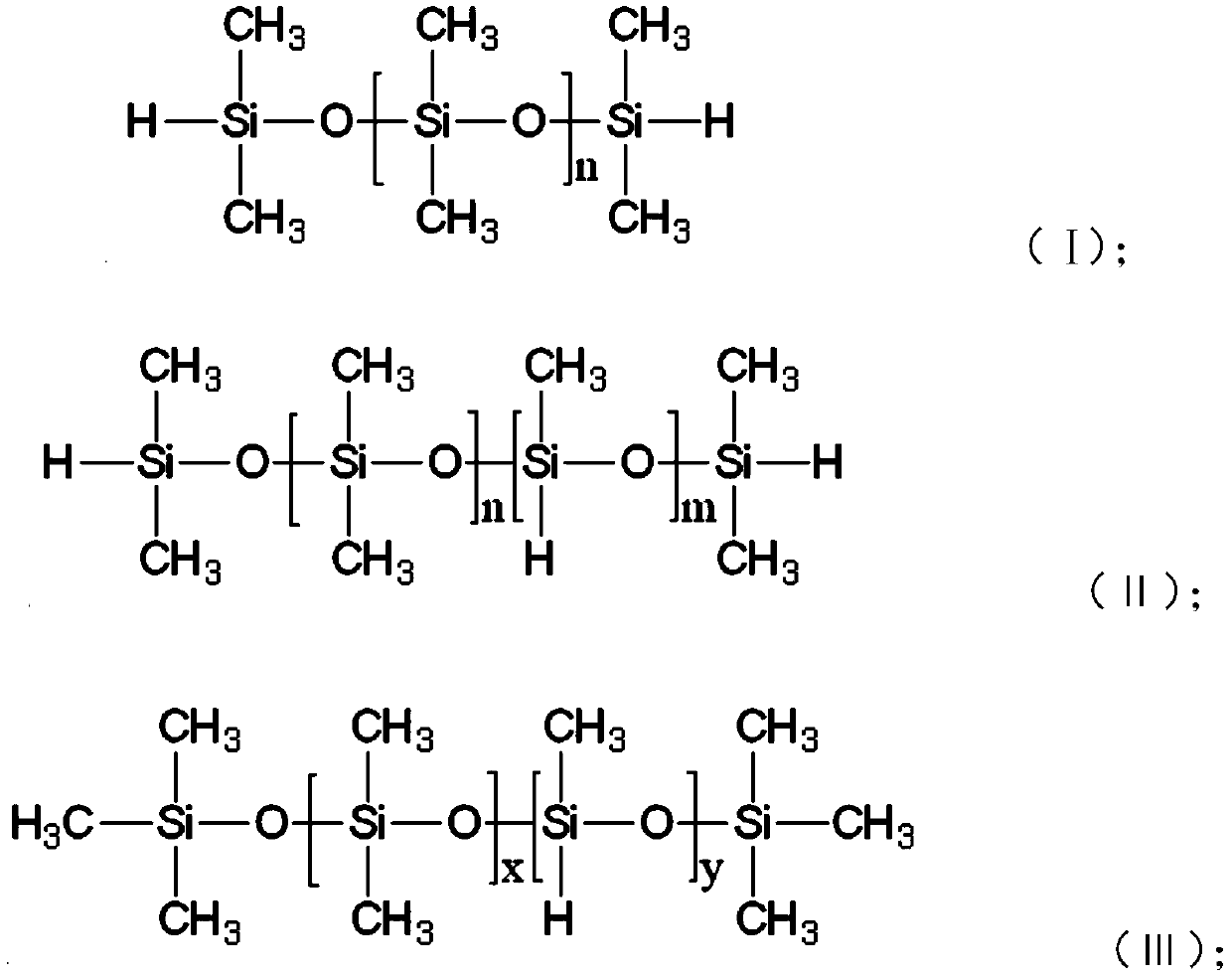

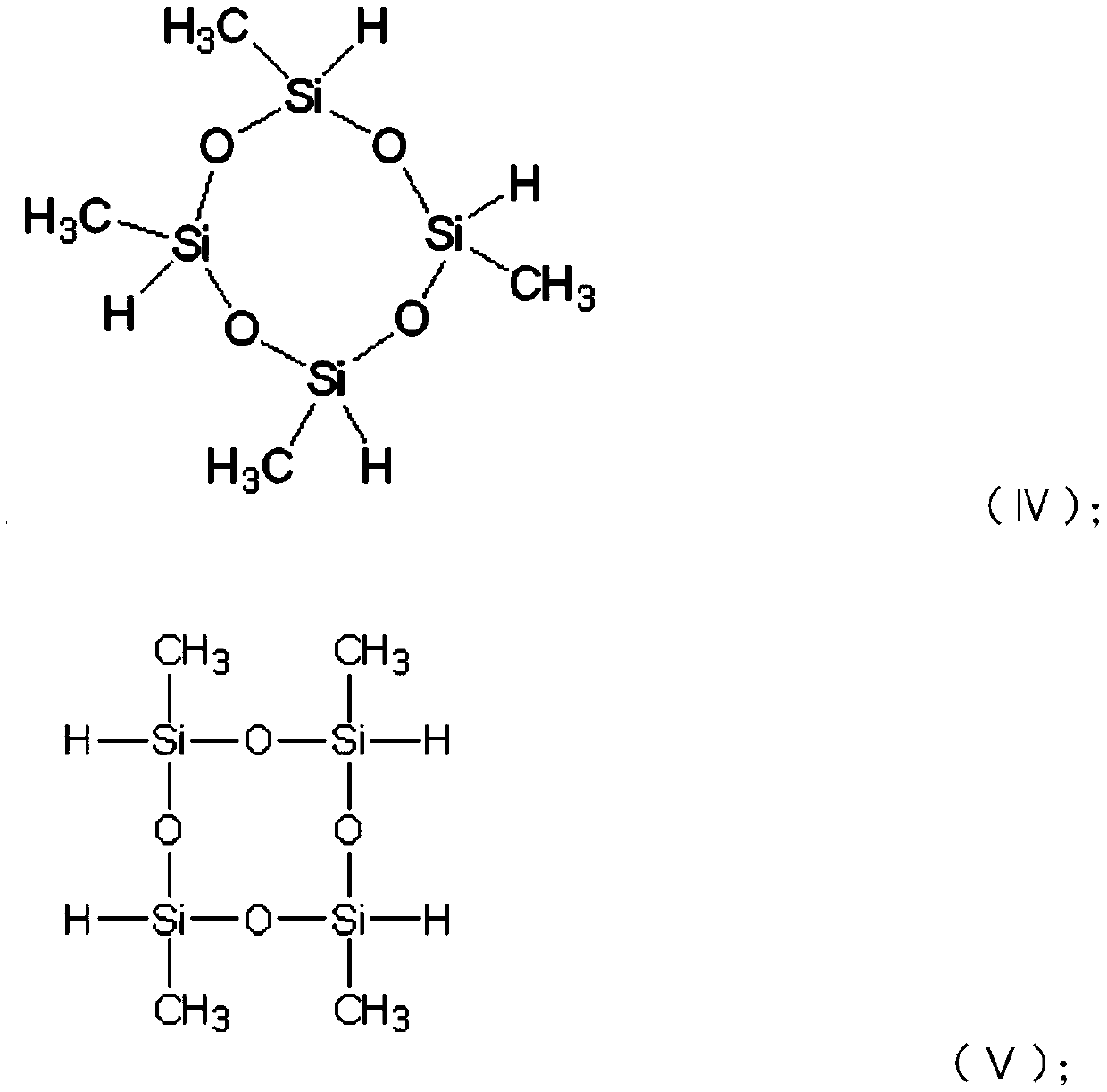

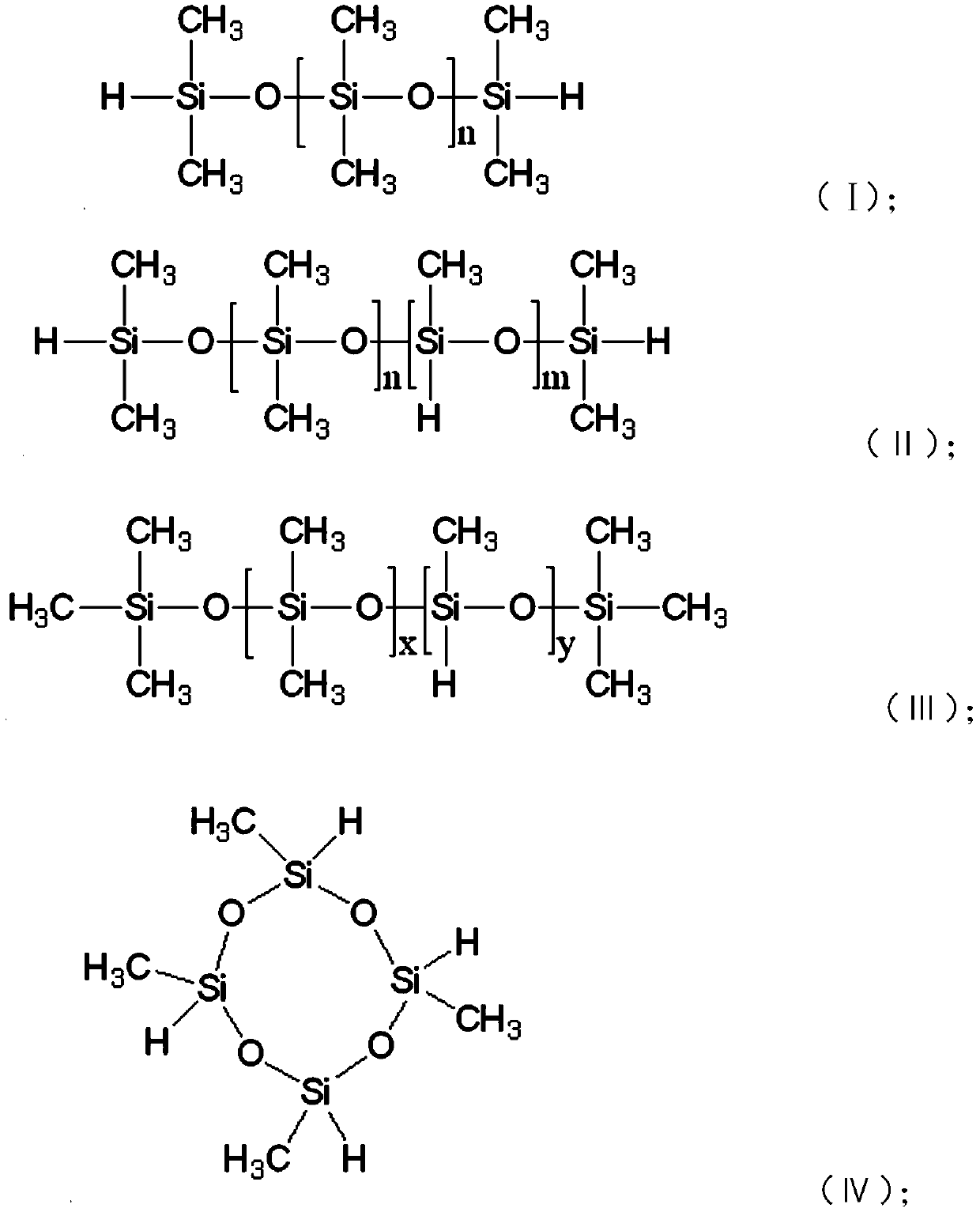

Image

Examples

preparation example Construction

[0049] The application also provides a preparation method of the silicone gel, comprising the following steps:

[0050] Mix vinyl silicone oil, terminal hydrogen-containing silicone oil, hydrogen-containing silicone oil and inhibitor to obtain component A;

[0051] Mix vinyl silicone oil and platinum catalyst to obtain component B;

[0052] The component A and the component B are mixed and cured to obtain a silicone gel.

[0053] The above-mentioned curing process is a curing process well known to those skilled in the art, and the present application has no particular limitation on this.

[0054] This application uses hydrogen-containing chain extenders and hydrogen-containing cross-linking agents to increase the softness and elasticity of the gel, and at the same time cooperates with an extremely low amount of platinum catalyst to obtain a gel with good light transmittance and excellent anti-yellowing performance. Silicone gel, this kind of silicone gel can be used in optic...

Embodiment 1

[0057] Mix polydimethylsiloxane with vinyl groups at both ends, hydrogen-terminated silicone oil, hydrogen-containing silicone oil and inhibitor according to the proportion to obtain component A;

[0058] Mix polydimethylsiloxane with vinyl groups at both ends and platinum catalyst according to the ratio to obtain component B;

[0059] Mix components A and B at a weight ratio of 1:1 to obtain a silicone gel after being uniformly cured.

[0060] Table 1 is the content data table of components A and B; the performance of the above-mentioned organosilicon gel is tested, and the results are shown in Table 8;

[0061] The component content data table of the organosilicon gel that table 1 embodiment 1 prepares

[0062]

[0063]

Embodiment 2

[0065] Mix polydimethylsiloxane with vinyl groups at both ends, hydrogen-terminated silicone oil, hydrogen-containing silicone oil and inhibitor according to the proportion to obtain component A.

[0066] Mix the polydimethylsiloxane with vinyl groups at both ends and the platinum catalyst according to the ratio to obtain component B.

[0067] Mix components A and B at a weight ratio of 1:1 to obtain silicone gel after uniform curing.

[0068] Table 2 is the content data table of components A and B; the performance of the above-mentioned organosilicon gel is tested, and the results are shown in Table 2;

[0069] The component content data table of table 2 embodiment 2

[0070]

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com