A kind of hb500 grade easy-welding wear-resistant steel with a thickness of 60-80 mm and its production method

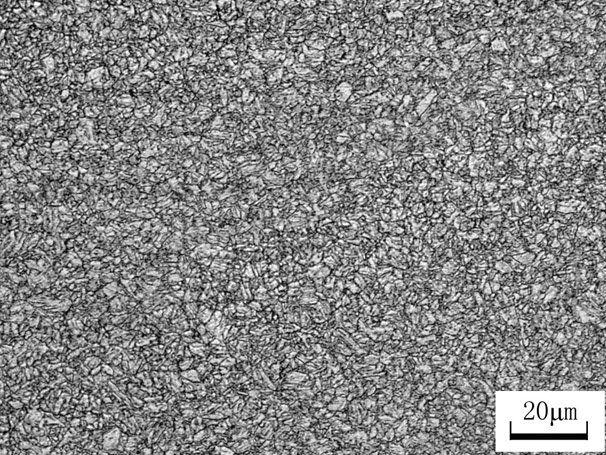

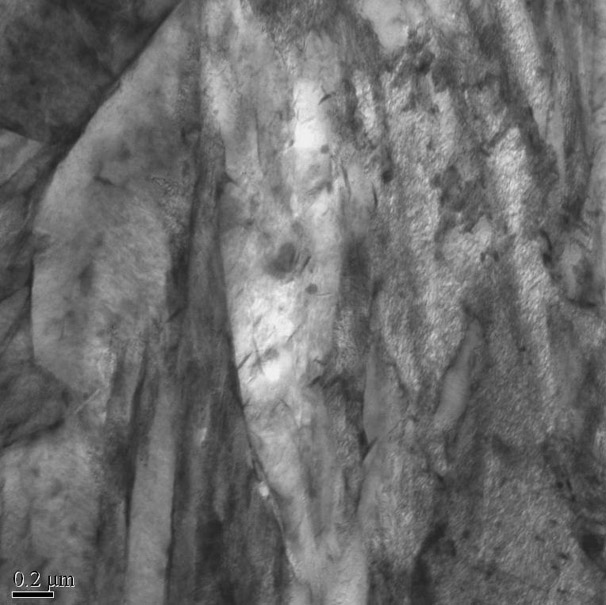

A technology of easy-to-weld and wear-resistant steel, applied in the field of HB500 easy-to-weld wear-resistant steel and production, it can solve the problems of affecting the welding efficiency and the welding quality cannot be guaranteed, and achieve good anti-embrittlement ability, and the grain is not easy to grow. The effect of large, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The present invention will be described in detail below:

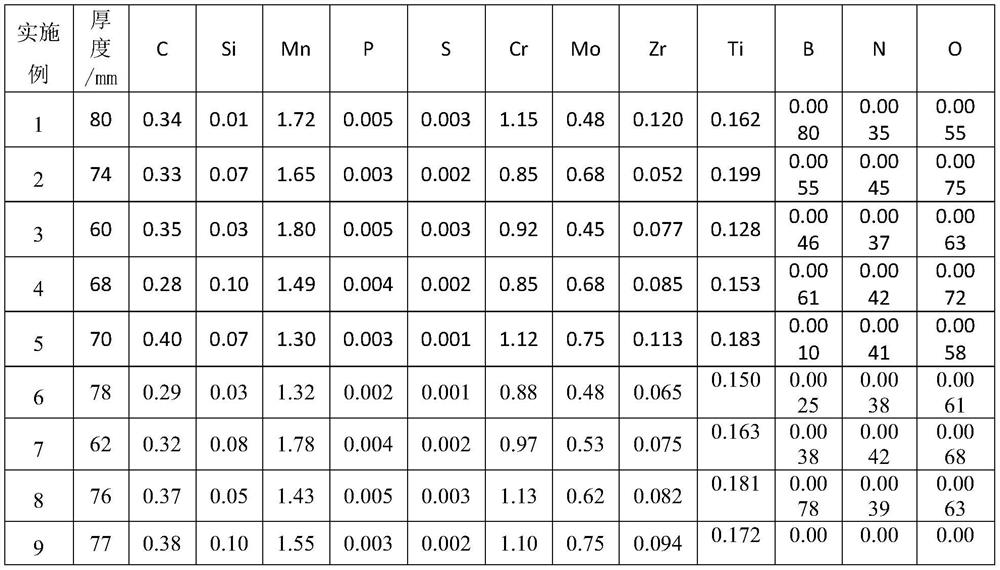

[0044]Table 1 is a list of various embodiments and the ratio of the present invention;

[0045]Table 2 is a list of the main process parameters of the embodiments of the present invention;

[0046]Table 3 is a list of various embodiments and contrast performance detection of the present invention.

[0047]Embodiments of the present invention are produced in accordance with the following process:

[0048]1) Frequently smelting, refining and continuously cast the blank, heating the slabs, the heating temperature is controlled at 1190 to 1230 ° C;

[0049]2) Rough rolling, the control is not less than 1050 ° C, the cumulative pressure is 50 ~ 60%;

[0050]3) Finishing rolling, the control finishing temperature does not exceed 960 ° C, the final rolling temperature is not less than 880 ° C, each diacetic rate is not less than 10%;

[0051]4) Cooling and allowed to room temperature, controlling the cooling temperature of no less than 825 ° C, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com