Ammonia process desulfurization tower smoke white eliminating structure and running method thereof

The technology of ammonia desulfurization and desulfurization tower is applied in the field of flue gas desulfurization, which can solve the problems of affecting the stability of cooling efficiency and whitening system unit, affecting the efficiency of flue gas whitening, failing to achieve cooling effect, etc. Good heat exchange effect and stable work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

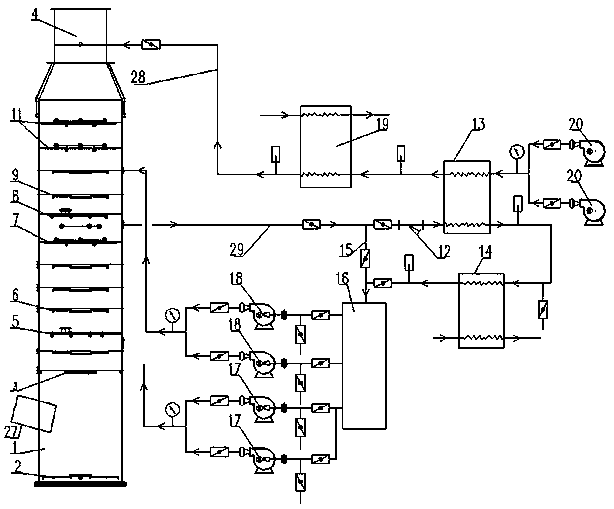

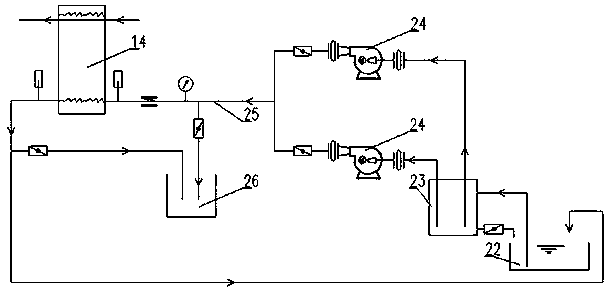

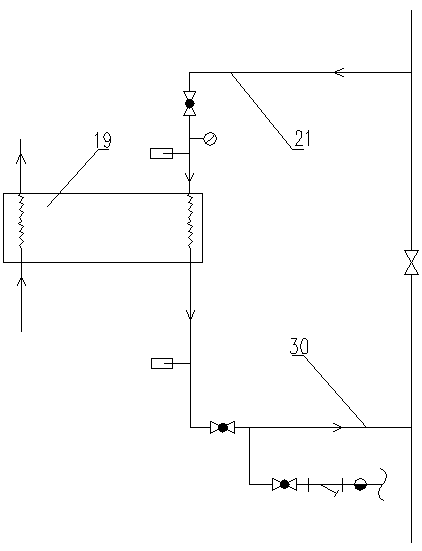

[0025] see Figure 1-Figure 3 , the embodiment of the present invention includes a desulfurization tower 1, a filter 12, an air heat exchanger 13, a plate heat exchanger 14, a circulating aqueous solution bypass pipe 15, a water washing circulation tank 16, a demister flushing water pump 17, a water washing circulation pump 18, Steam heater 19, centrifugal fan 20, power plant waste heat steam pipeline 21, power plant cooling tower reservoir 22, self-priming tank 23, cooling water pump 24, cooling water pipeline 25, drainage pit 26, hot air pipeline 28, circulating water solution pipeline 29 And power plant steam pipeline 30.

[0026] The desulfurization tower 1 is provided with an oxidation section 2, a prewashing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com