Release film for ceramic green sheet production and method for producing the same

A ceramic green sheet and manufacturing method technology, applied in chemical instruments and methods, manufacturing tools, capacitor manufacturing, etc., can solve the problem of poor compatibility, deterioration of surface roughness of mold release layer, deterioration of defective rate of laminated ceramic capacitors, etc. problem, to achieve the effect of reducing pinholes and good peelability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

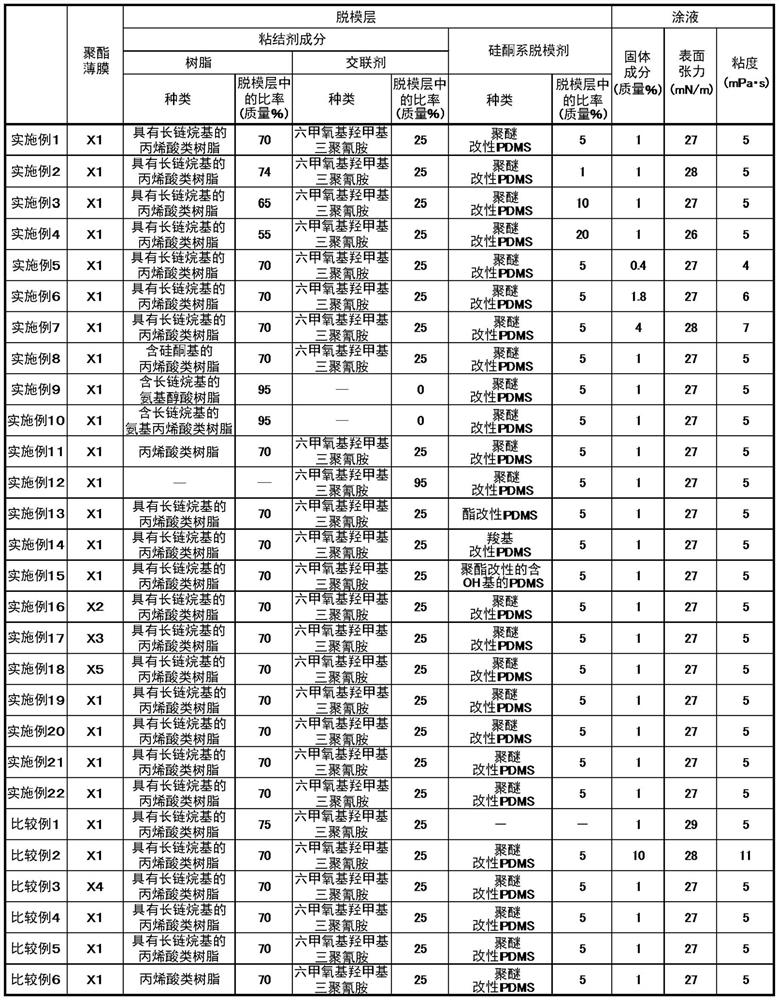

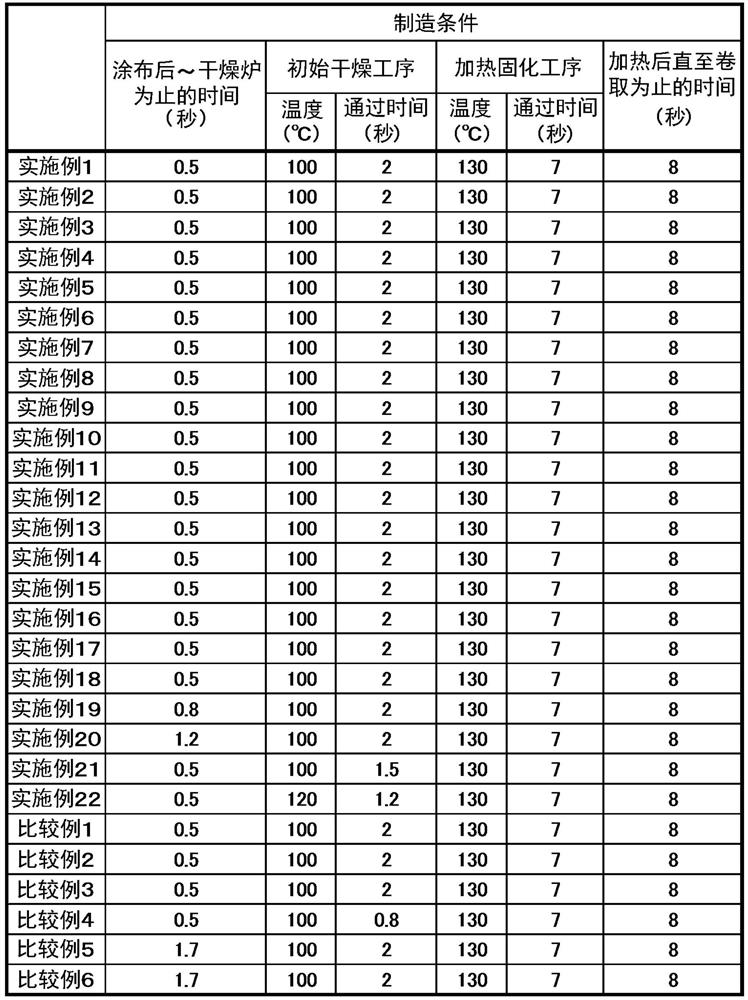

[0185] After passing the coating solution 1 of the following composition through a filter capable of removing 99% or more of foreign matter of 0.5 μm or more, it is coated on the surface layer A of the laminated film X1 by reverse gravure so that the coating film thickness (wet film thickness) After becoming 5 μm, it is adjusted so that it enters the initial drying oven within 0.5 seconds. After drying at 100° C. for 2 seconds in the initial drying oven, it was continuously put into a heating and curing step and heated at 130° C. for 7 seconds. After the heating and curing step, it was taken up into a roll after 8 seconds to obtain a release film for producing an ultra-thin ceramic green sheet. Table 3 shows the results of measuring the film thickness, surface roughness, surface free energy, and curl of the obtained release film. Furthermore, when the ceramic slurry was coated on the obtained release film, and the applicability, detachability, and pinholes were evaluated, fav...

Embodiment 2~4、 comparative example 1

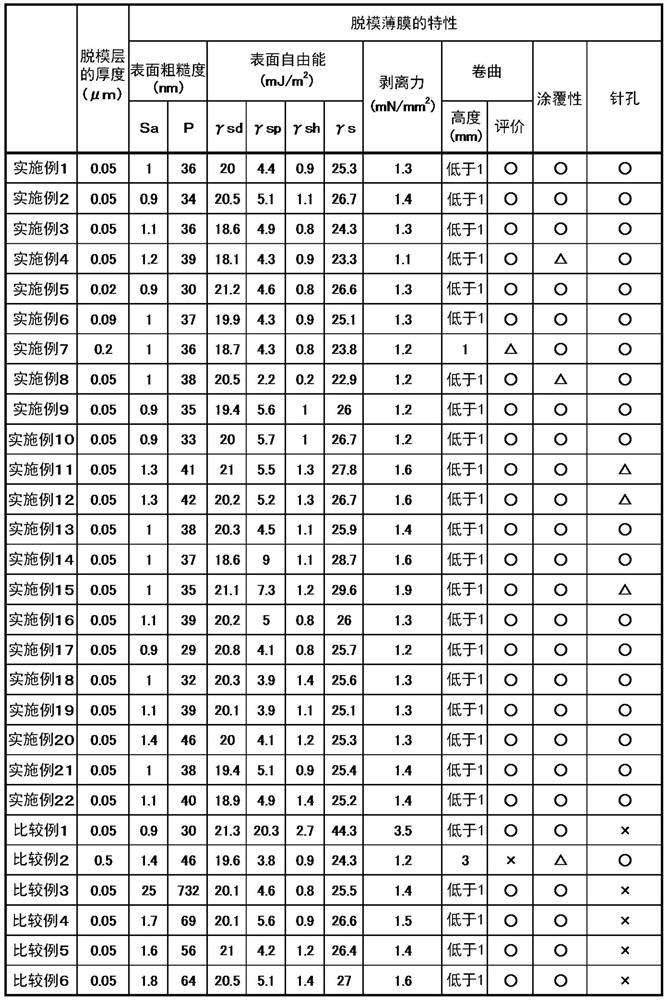

[0197] Except having changed the composition of the coating liquid 1 so that it might become the ratio shown in Table 1, it carried out similarly to Example 1, and produced the mold release film for ultrathin-layer ceramic green sheet manufacture. As a result of evaluating the obtained release film, the peeling force was also good and good results were obtained for Examples in which a silicone-based release agent was added, but in Comparative Example 1 that did not contain a silicone-based release agent, the peeling force decreased. As a result, when the ceramic green sheet is peeled off from the release film, defective spots such as pinholes are likely to be generated.

Embodiment 5~7、 comparative example 2

[0199] Except for changing the resin ratio of the coating solution 1 to that shown in Table 1 and changing the film thickness of the release layer, a release film for producing ultra-thin ceramic green sheets was produced in the same manner as in Example 1. .

[0200] The obtained release film was evaluated, and it was a good result that there was no curling in Example in which the thickness of the release layer was 0.2 μm or less, but in Comparative Example 2 in which the thickness of the release layer was 0.5 μm, the curl was large. worsening results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com