Novel VOCs absorbent and preparation method thereof

An absorbent and a new type of technology, applied in the field of new VOCs absorbent and its preparation, can solve the problems of high recycling costs, difficult regeneration, and low adsorption capacity, and achieve the effects of improving absorption rate, compatibility, and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

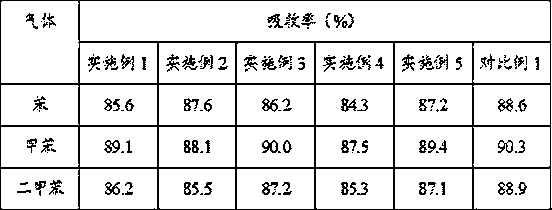

Examples

Embodiment 1

[0024] A novel VOCs absorbent, wherein the components are by weight: including 50 parts of biodiesel, 30 parts of nonionic surfactants, 15 parts of co-surfactants, 0.5 parts of camphene, 1-butyl-3-methyl 8 parts of imidazolium hexafluorophosphate, 3 parts of 1-butyl-3-methylimidazolium tetrafluoroborate and appropriate amount of water.

[0025] A kind of novel VOCs absorbent, its preparation method comprises the following steps:

[0026] S1: Add 1-butyl-3-methylimidazolium tetrafluoroborate into water and mix evenly, then add nonionic surfactant dropwise to the mixture at a stirring speed of 80r / min, among which the nonionic surface The rate of addition of the active agent is 1.5 parts / min, and after the addition of the nonionic surfactant, continue to stir for 30 minutes to obtain the mixed component A;

[0027] S2: under stirring, 1-butyl-3-methylimidazolium hexafluorophosphate, camphene and co-surfactant are added to biodiesel in sequence and mixed evenly to obtain mixed c...

Embodiment 2

[0033] A novel VOCs absorbent, wherein the components are by weight: including 60 parts of biodiesel, 16 parts of non-ionic surfactant, 8 parts of co-surfactant, 3.5 parts of camphene, 1-butyl-3-methyl 6 parts of imidazolium hexafluorophosphate, 6 parts of 1-butyl-3-methylimidazolium tetrafluoroborate and appropriate amount of water.

[0034] A kind of novel VOCs absorbent, its preparation method comprises the following steps:

[0035] S1: Add 1-butyl-3-methylimidazolium tetrafluoroborate into water and mix evenly, then add nonionic surfactant dropwise to the mixture at a stirring speed of 90r / min, among which the nonionic surface The rate of addition of the activating agent is 1.6 parts / min, and after the addition of the nonionic surfactant, the stirring is continued for 40 minutes to obtain the mixed component A;

[0036] S2: under stirring, 1-butyl-3-methylimidazolium hexafluorophosphate, camphene and co-surfactant are added to biodiesel in sequence and mixed evenly to obt...

Embodiment 3

[0042] A novel VOCs absorbent, wherein the components are by weight: including 70 parts of biodiesel, 24 parts of nonionic surfactant, 12 parts of co-surfactant, 2.5 parts of camphene, 1-butyl-3-methyl 4 parts of imidazolium hexafluorophosphate, 8 parts of 1-butyl-3-methylimidazolium tetrafluoroborate and appropriate amount of water.

[0043] A kind of novel VOCs absorbent, its preparation method comprises the following steps:

[0044] S1: Add 1-butyl-3-methylimidazolium tetrafluoroborate into water and mix evenly, then add nonionic surfactant dropwise to the mixture at a stirring speed of 100r / min, among which the nonionic surface The rate of addition of the active agent was 1.7 parts / min, and after the nonionic surfactant was added dropwise, the stirring was continued for 45 minutes to obtain the mixed component A;

[0045] S2: under stirring, 1-butyl-3-methylimidazolium hexafluorophosphate, camphene and co-surfactant are added to biodiesel in sequence and mixed evenly to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com