A Side-illuminated Reactor for Studying Photothermal Coupled Catalytic Splitting of Water for Hydrogen Production

A photocatalytic reactor and catalytic decomposition technology, which is applied in the field of side-illuminated reactors, can solve the problem that the photocatalytic reactor cannot work at a relatively high temperature, and can ensure accuracy and reliability, good heat preservation and temperature control. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

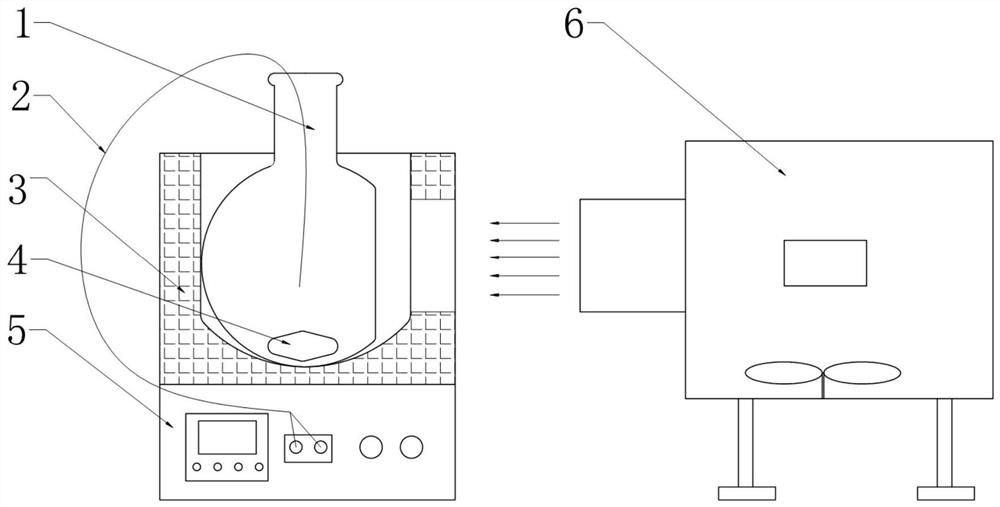

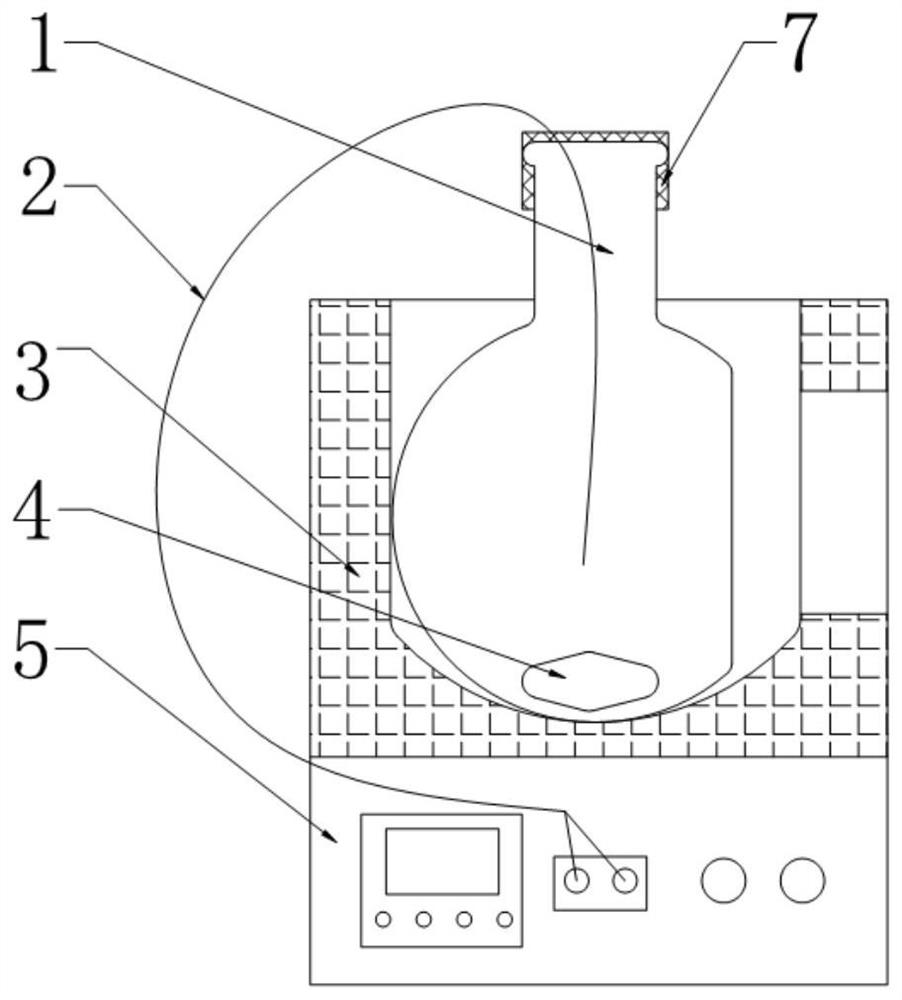

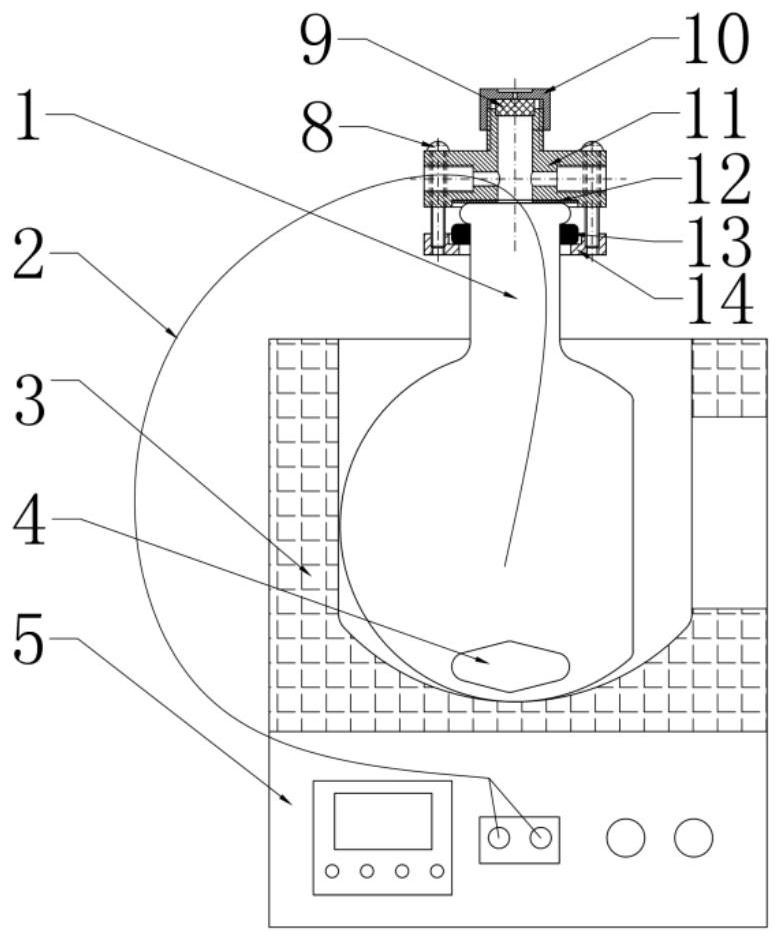

[0040] like Figure 1 to Figure 6 As shown, the present invention provides a side-illuminated reactor for researching photothermal coupled catalytic decomposition of water for hydrogen production, including a heating and control unit, a stirring unit, a sampling unit and a side-illuminated photocatalytic reactor 1; wherein, the heating And the control unit includes a temperature measuring thermocouple 2, a heating mantle 3 and a control panel 5, the stirring unit includes a magnetic stirrer 4, and the sampling unit provides three forms in the present invention according to different temperature and pressure requirements, which are the simplest Silicone bottle stopper 7, or fixed screw 8, sampling septum 9, sampling septum pressure cap 10, sampler upper flange cover 11, silicone sealing flat gasket 12, polytetrafluoroethylene retaining ring 13 and lower end flange cover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com