Reinforced aluminum ash desalting and denitriding method

A technology for strengthening aluminum and desalination, applied in the field of strengthening aluminum ash desalination and denitrification, which can solve the problems of high reagent cost, limited solubility, mild hydrolysis conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

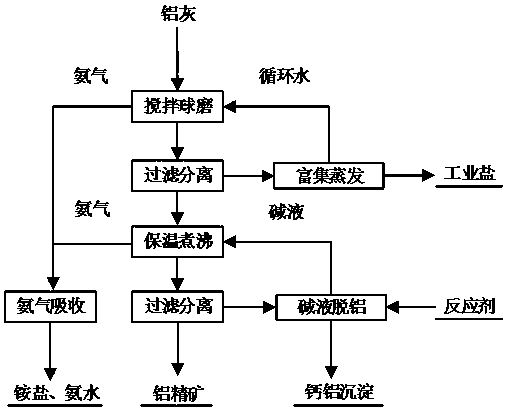

Image

Examples

Embodiment 1

[0025] A method for strengthening aluminum ash desalination and denitrification, comprising the following steps:

[0026] (1) Take aluminum ash and dry grind it to below 100 mesh. The main chemical composition of the aluminum ash is Al 2 o 3 54.98%, SiO 2 9.56%, Na 2 O 3.32%, AlN 16.82%;

[0027] (2) Take 100 g of the aluminum ash and add 200 g of water to mix, stir and ball mill for 10 minutes at room temperature to obtain a fine slurry, use dilute hydrochloric acid to absorb the ammonia gas generated, filter the fine slurry to obtain a filter cake and filtrate, and the filtrate is enriched and evaporated recovery of industrial salt;

[0028] (3) Add sodium hydroxide solution with a mass fraction of 5% to the filter cake, stir and keep the temperature at 50 °C for 4 h, and use dilute hydrochloric acid to absorb the ammonia gas generated by stirring ball milling and stirring heat preservation;

[0029] (4) Filtrate the obtained slurry, and the aluminum nitride content i...

Embodiment 2

[0031] A method for strengthening aluminum ash desalination and denitrification, comprising the following steps:

[0032] (1) Take aluminum ash and dry grind it to below 100 mesh. The main chemical composition of the aluminum ash is Al 2 o 3 68.78%, SiO 2 1.24%, Na 2 O 2.19%, AlN 12.54%;

[0033] (2) Take 100 g of the aluminum ash and add 100 g of water to mix, stir and ball mill at room temperature for 20 minutes to obtain a fine slurry, use dilute sulfuric acid to absorb the ammonia gas generated, filter the fine slurry to obtain a filter cake and filtrate, and the filtrate is enriched and evaporated recovery of industrial salt;

[0034] (3) Add sodium hydroxide solution with a mass fraction of 10% to the filter cake, stir and keep the temperature at 75 °C for 2 h, and use dilute sulfuric acid to absorb the ammonia gas generated by stirring ball milling and stirring heat preservation;

[0035] (4) Filtrate the obtained slurry, and the aluminum nitride content in the r...

Embodiment 3

[0037] A method for strengthening aluminum ash desalination and denitrification, comprising the following steps:

[0038] (1) Take aluminum ash and dry grind it to below 100 mesh. The main chemical composition of the aluminum ash is Al 2 o 3 46.44%, SiO 2 3.26%, Na 2 O 4.72%, AlN 28.18%;

[0039] (2) Take 100 g of the aluminum ash and add 300 g of water to mix, stir and ball mill for 30 minutes at room temperature to obtain a fine slurry, use water to absorb ammonia gas, filter the fine slurry to obtain a filter cake and filtrate, and the filtrate is enriched and evaporated for recovery industrial salt;

[0040] (3) Add sodium hydroxide solution with a mass fraction of 20% to the filter cake, stir and keep the temperature at 100 °C for 1 h, and use water to absorb the ammonia gas generated by stirring ball milling and stirring for heat preservation;

[0041] (4) Filtrate the obtained slurry, and the aluminum nitride content in the remaining residue is 0.45%, which is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com