Direct-coating water-based single-component ceramic tile renovating coating and preparation method thereof

A one-component, direct-coating technology, applied in the field of architectural coatings, it can solve the problems of poor adhesion, sagging, difficult adhesion of tiles, etc., and achieve the effects of improved dry and wet adhesion, simple application and low VOC content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

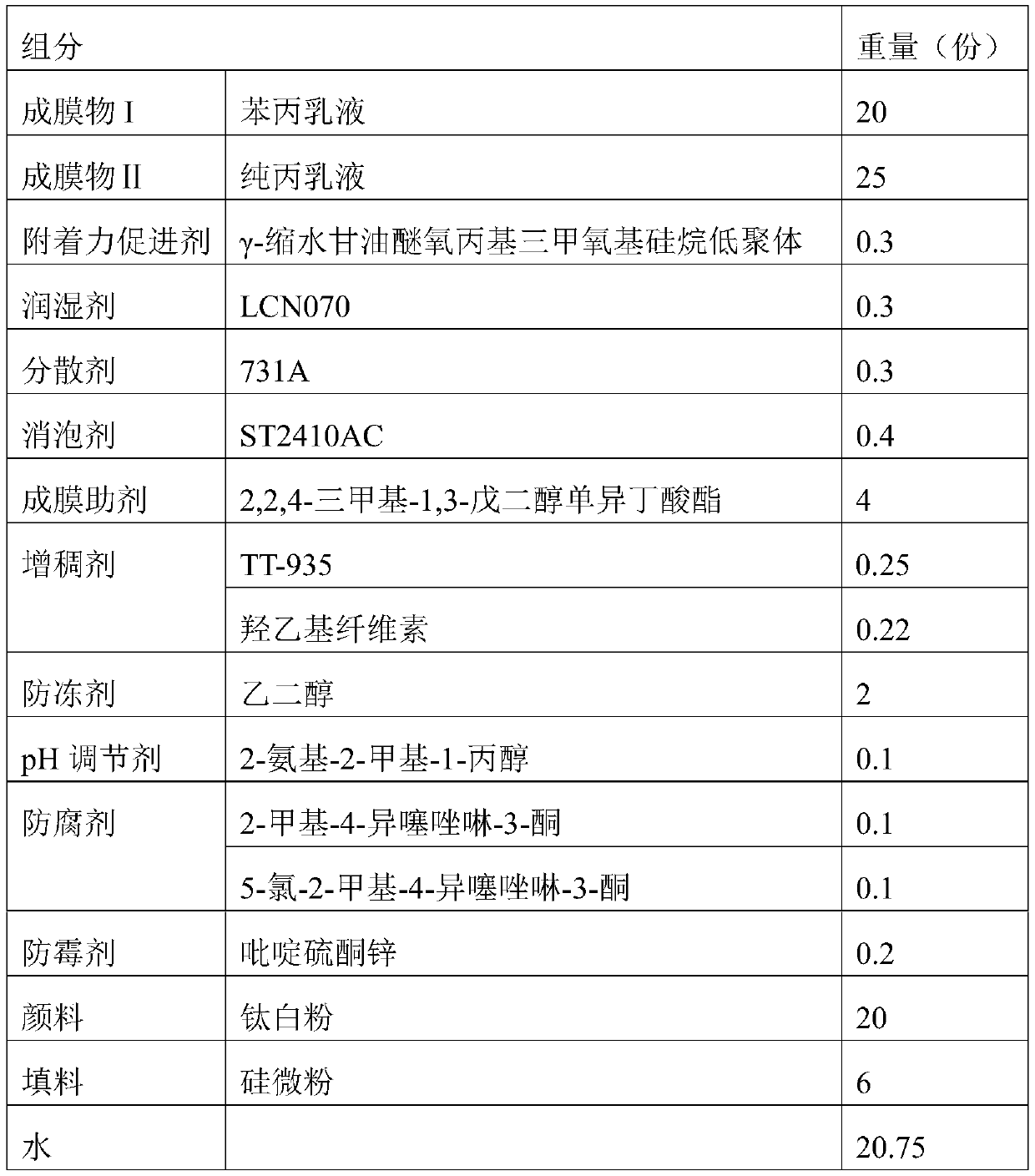

[0034] A kind of direct-coating type water-based one-component ceramic tile refurbishment coating comprises the following components by weight:

[0035]

[0036] (1) Add the dispersant to water, and disperse until uniform at a speed of 750 rpm;

[0037] (2) Add wetting agent, film-forming aid, antifreeze, defoamer, cellulose thickener and pH regulator in sequence, and disperse until uniform at a speed of 750 rpm;

[0038] (3) Add fillers and pigments, increase the speed to 1500 rpm, and disperse until uniform;

[0039] (4) Reduce the speed to 900 rpm, add antifungal agent, preservative, film former I, film former II, adhesion promoter and hydrophobic modified alkali-swellable thickener in sequence, and disperse until uniform, that is A direct-to-apply water-based one-component tile renovation paint.

Embodiment 2

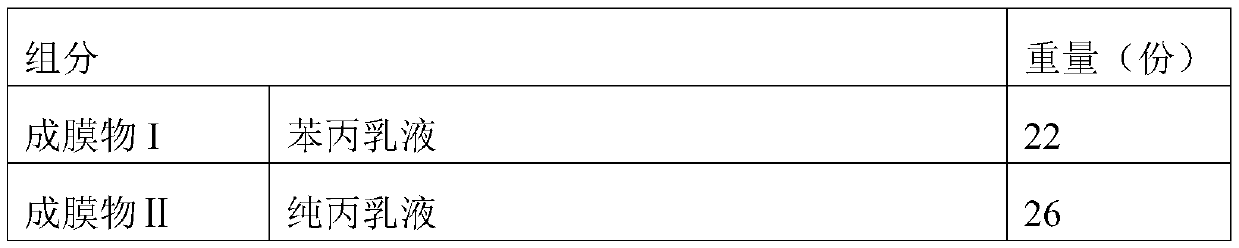

[0041] A kind of direct-coating type water-based one-component ceramic tile refurbishment coating comprises the following components by weight:

[0042]

[0043]

[0044] (1) Add the dispersant to water, and disperse until uniform at a speed of 750 rpm;

[0045] (2) Add wetting agent, film-forming aid, antifreeze, defoamer, cellulose thickener and pH regulator in sequence, and disperse until uniform at a speed of 750 rpm;

[0046] (3) Add filler, increase the rotating speed to 1500 rpm, and disperse until uniform;

[0047] (4) Reduce the speed to 900 rpm, add antifungal agent, preservative, film former I, film former II, adhesion promoter and hydrophobic modified alkali-swellable thickener in sequence, and disperse until uniform, that is A direct-to-apply water-based one-component tile renovation paint.

Embodiment 3

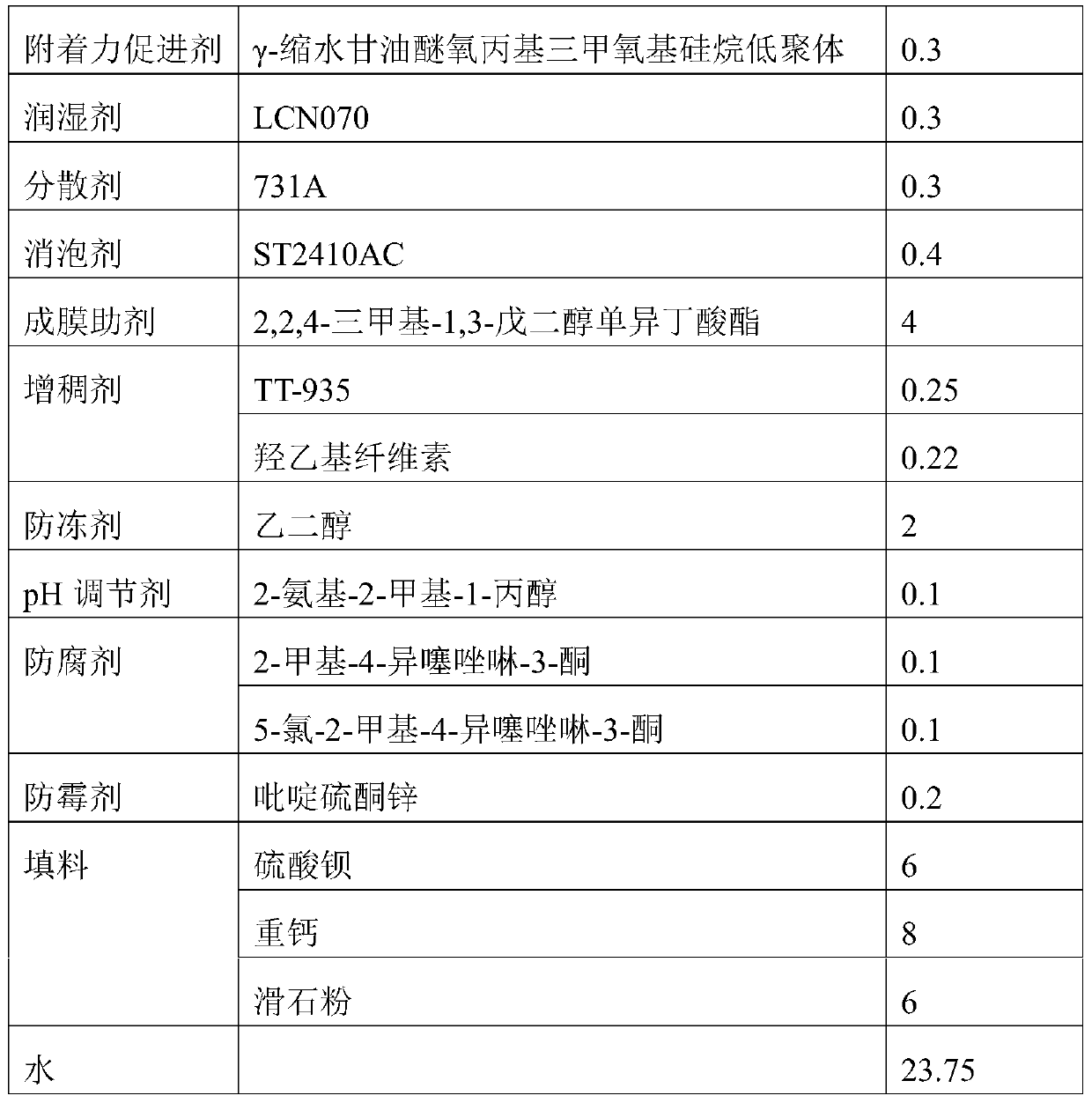

[0049] A kind of direct-coating type water-based one-component ceramic tile refurbishment coating comprises the following components by weight:

[0050]

[0051]

[0052] The preparation method of the above-mentioned direct coating type water-based one-component ceramic tile renovation coating may further comprise the steps:

[0053] (1) Add the dispersant to water, and disperse until uniform at a speed of 750 rpm;

[0054] (2) Add wetting agent, film-forming aid, antifreeze, defoamer, cellulose thickener and pH regulator in sequence, and disperse until uniform at a speed of 750 rpm;

[0055] (3) Add filler, increase the rotating speed to 1500 rpm, and disperse until uniform;

[0056] (4) Reduce the speed to 900 rpm, add antifungal agent, preservative, film former I, film former II, adhesion promoter and hydrophobic modified alkali-swellable thickener in sequence, and disperse until uniform, that is A direct-to-apply water-based one-component tile renovation paint.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com