Surface treatment process of valve metal part

A technology for surface treatment and metal parts, applied in the field of surface treatment technology of metal parts of valves, can solve the problems of unclear production classification, affecting production progress, uneven quality levels, etc., achieve high-efficiency quality inspection, improve product production quality, Improve the effect of high-efficiency work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

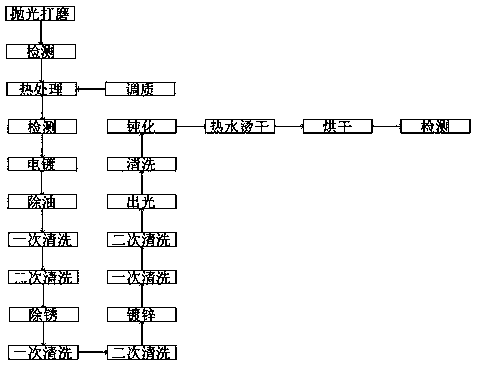

[0031] see figure 1 , the present invention provides a technical solution for the surface treatment process of valve metal parts: a surface treatment process for valve metal parts, characterized in that it includes the following steps:

[0032] S1: Polishing and grinding: clamp the cast valve metal parts in the equipment to be polished for the next polishing and grinding.

[0033] S2: The polished and polished valve parts are inspected by quality inspectors for their appearance, specifications and dimensions. After passing the inspection, proceed to the next step, and return to the previous process for reprocessing if they are unqualified.

[0034] S3: Carry out heat treatment on qualified valve parts after polishing and grinding. Here, quenching and tempering heat treatment is adopted, and the rigidity and toughness of valve parts are improved through quenching and high temperature tempering. After heat treatment, quality inspectors conduct heat treatment qualified inspection...

Embodiment 2

[0050] see figure 1 , the present invention provides a technical solution for the surface treatment process of valve metal parts: a surface treatment process for valve metal parts, characterized in that it includes the following steps:

[0051] S1: Polishing and grinding: clamp the cast valve metal parts in the equipment to be polished for the next polishing and grinding.

[0052] S2: The polished and polished valve parts are inspected by quality inspectors for their appearance, specifications and dimensions. After passing the inspection, proceed to the next step, and return to the previous process for reprocessing if they are unqualified.

[0053] S3: Carry out heat treatment on qualified valve parts after polishing and grinding. Here, quenching and tempering heat treatment is adopted, and the rigidity and toughness of valve parts are improved through quenching and high temperature tempering. After heat treatment, quality inspectors conduct heat treatment qualified inspection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com