High-stability zero-rigidity micro-vibration isolation device based on magneto-rheological technology

A high-stability, zero-stiffness technology, applied in vibration suppression adjustment, non-rotational vibration suppression, shock absorbers, etc., can solve problems such as complex structure, relatively high processing accuracy requirements, unsatisfactory service life and maintenance, etc., to achieve The effect of simple structure and low natural frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be further described in detail below. The content not described in detail in the embodiments of the present invention belongs to the prior art known to those skilled in the art.

[0020] The preferred embodiment of the high-stability zero-stiffness micro-vibration isolation device based on magnetorheological technology of the present invention is:

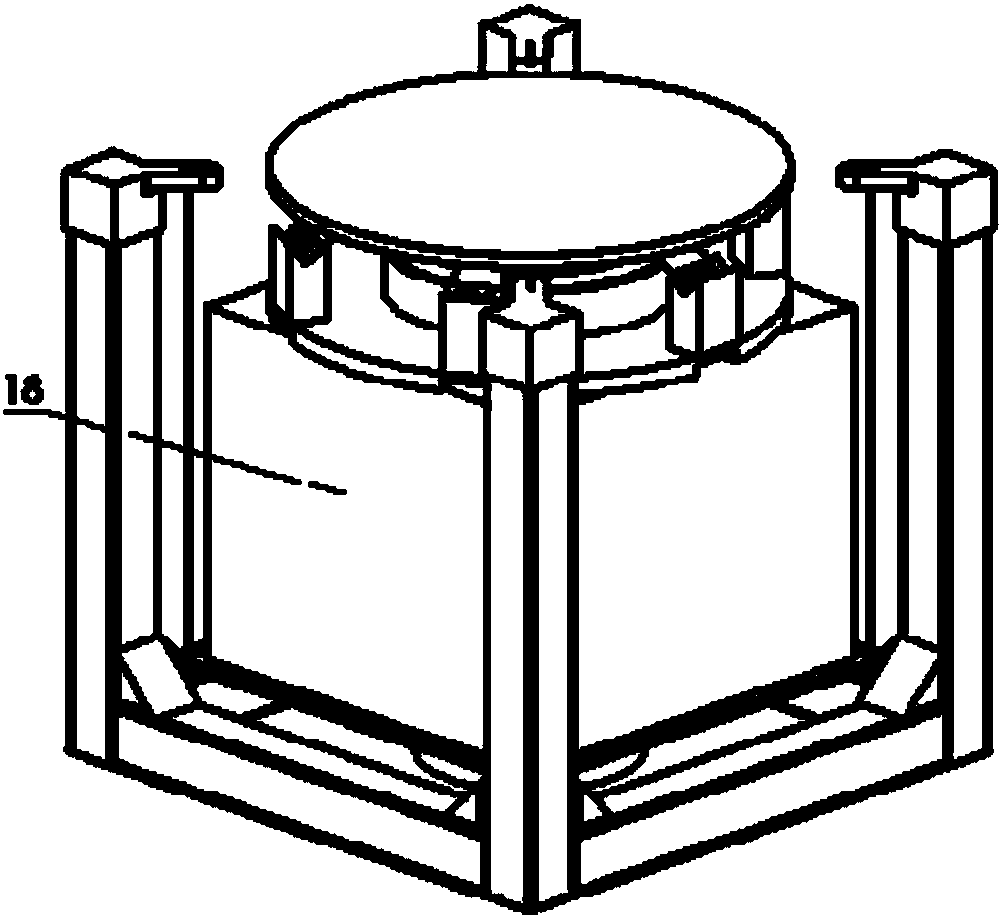

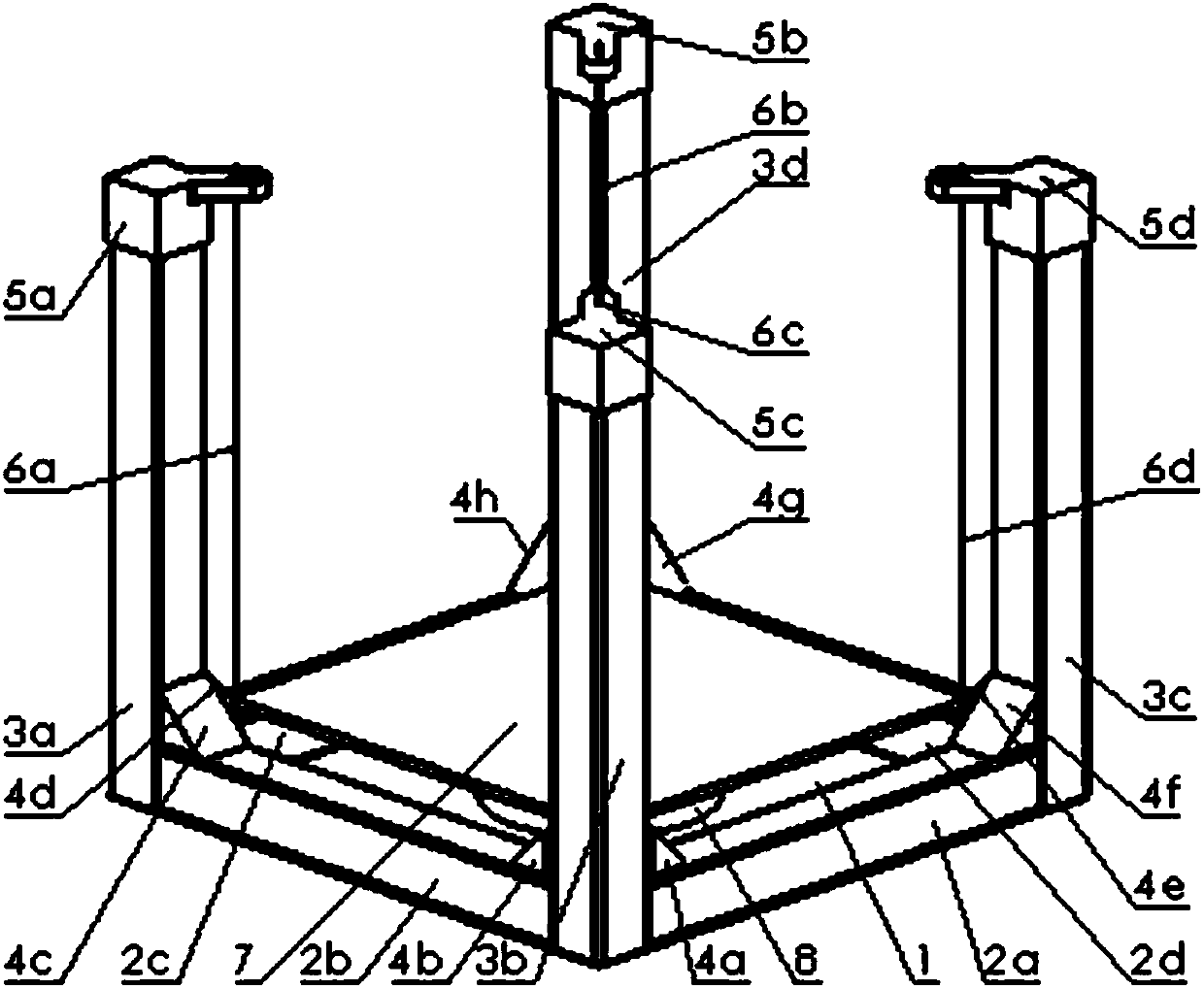

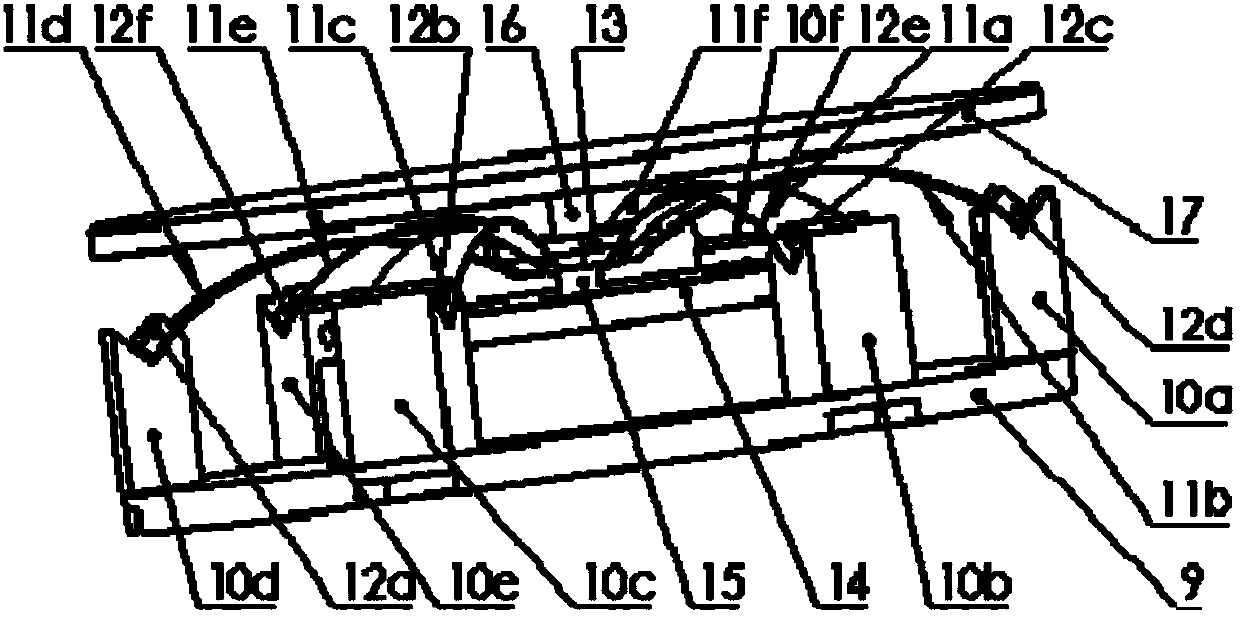

[0021] It includes a horizontal vibration isolation support frame and a vertical vibration isolation structure, the workbench is located on the vertical vibration isolation structure, and the vertical vibration isolation structure is placed on the horizontal vibration isolation platform of the horizontal vibration isolation support frame;

[0022] The horizontal vibration isolation support frame includes a first vertical truss, a second vertical truss, a third vertical truss, a fourth vertical truss, a first horizontal truss, a second horizontal truss, a third horizontal truss, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com