A water-coolable rock multi-field coupling test comprehensive loading device and method

A loading device and water cooling technology, which is applied to measuring devices, using stable tension/pressure to test material strength, and preparation of test samples, etc., can solve problems such as long oil discharge time, error in test results, and single function of the device , to achieve strong integration and comprehensiveness, avoid burns, and improve precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

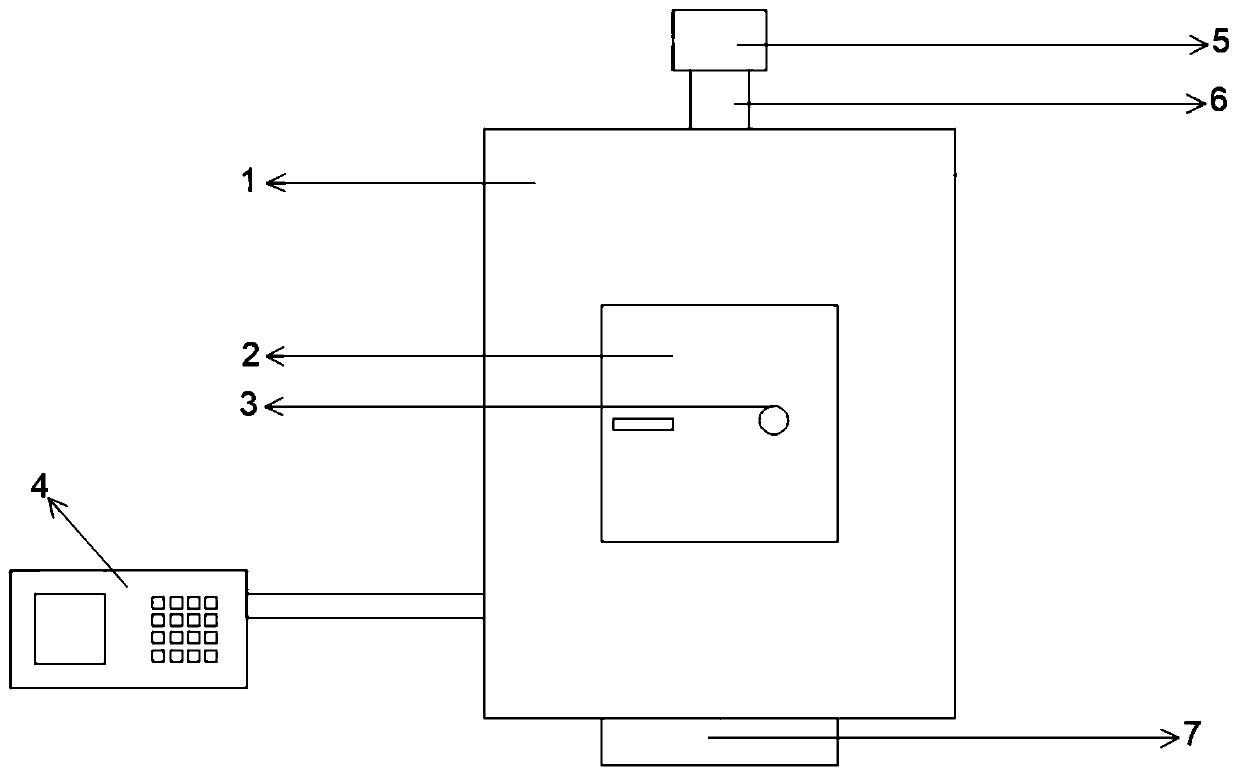

[0047] This embodiment discloses a method of using a water-coolable rock multi-field coupling test comprehensive loading device, including the following steps:

[0048] Step 1: Place the water-coolable rock multi-field coupling test comprehensive loading device on the workbench of the uniaxial press.

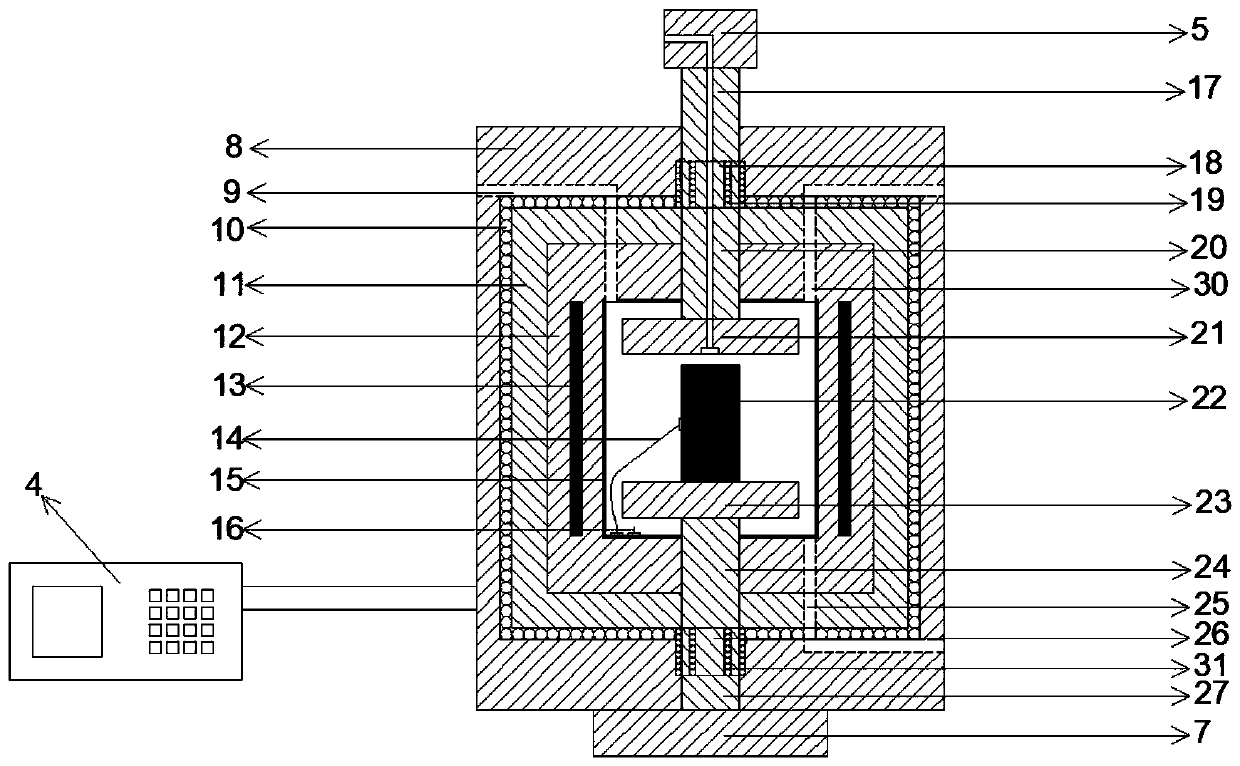

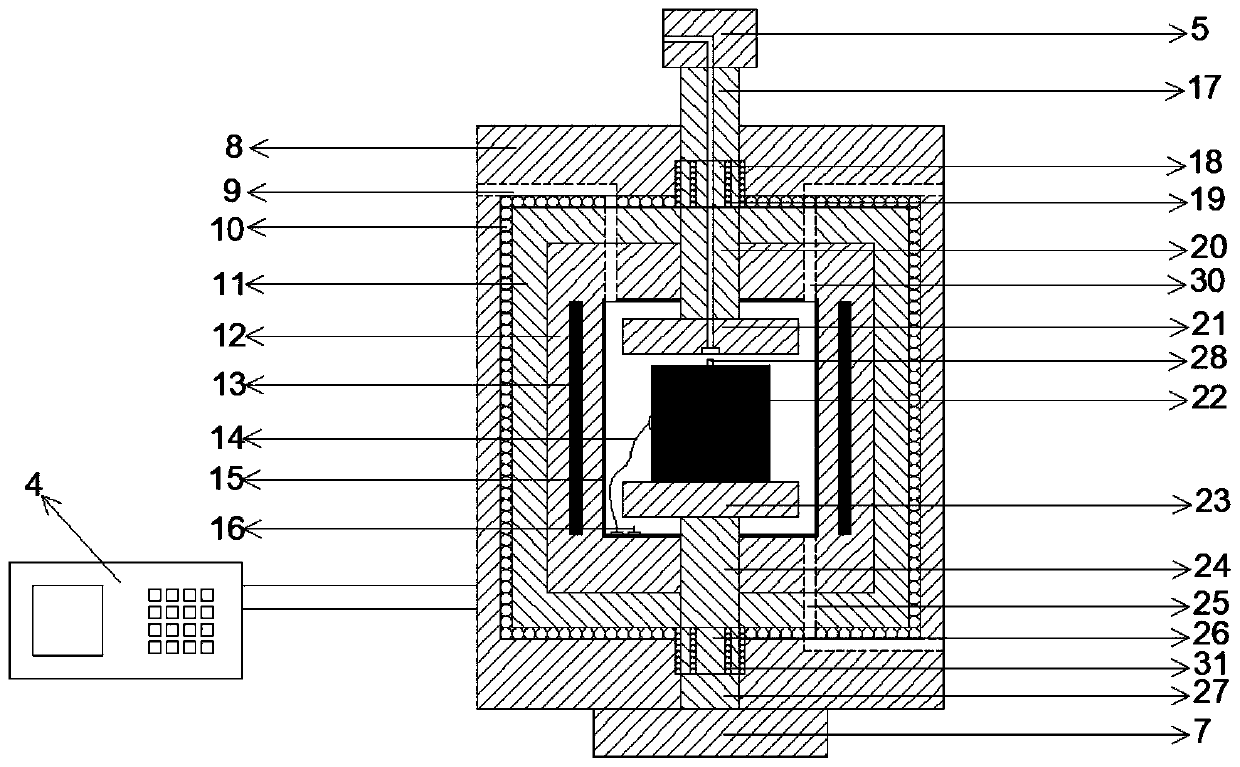

[0049] Step 2: Place the rock specimen 22 on the bearing mechanism, the shaft-hydraulic loading mechanism is in contact with the pressure mechanism of the uniaxial press, and the shaft-hydraulic loading mechanism and the bearing mechanism compress the rock specimen 22 according to the actual situation Choose to perform a hydraulic split test, Brazilian split test or uniaxial compression test.

[0050] If it is necessary to carry out the hydraulic splitting test, the rock test piece 22 needs to be embedded in a sleeve pipe 28 when it is made. The sleeve pipe 28 cannot be completely embedded in the rock test piece 22. A sealing rubber ring matching the sleeve 28 is placed in the ...

Embodiment 3

[0059] This embodiment discloses a method using a water-coolable rock multi-field coupling test comprehensive loading device. After the rock test piece 22 reaches the target temperature, use the coolant inlet pipe 9 to inject coolant into the furnace, and open the pressure relief pipe at the same time 30. After cooling the rock specimen 22 and drying it, perform a uniaxial compression test, a hydraulic splitting test or a Brazilian splitting test. The other steps of the test are the same as in Example 2, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com