Hydro-magnetic linear actuator

An actuator and fluid bearing technology, applied in the field of actuators including linear motors, can solve the problems of equipment cost and size increase, indistinguishable, reduce the peak frequency of the actuator, etc., achieve low mechanical friction and wear, low The effect of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

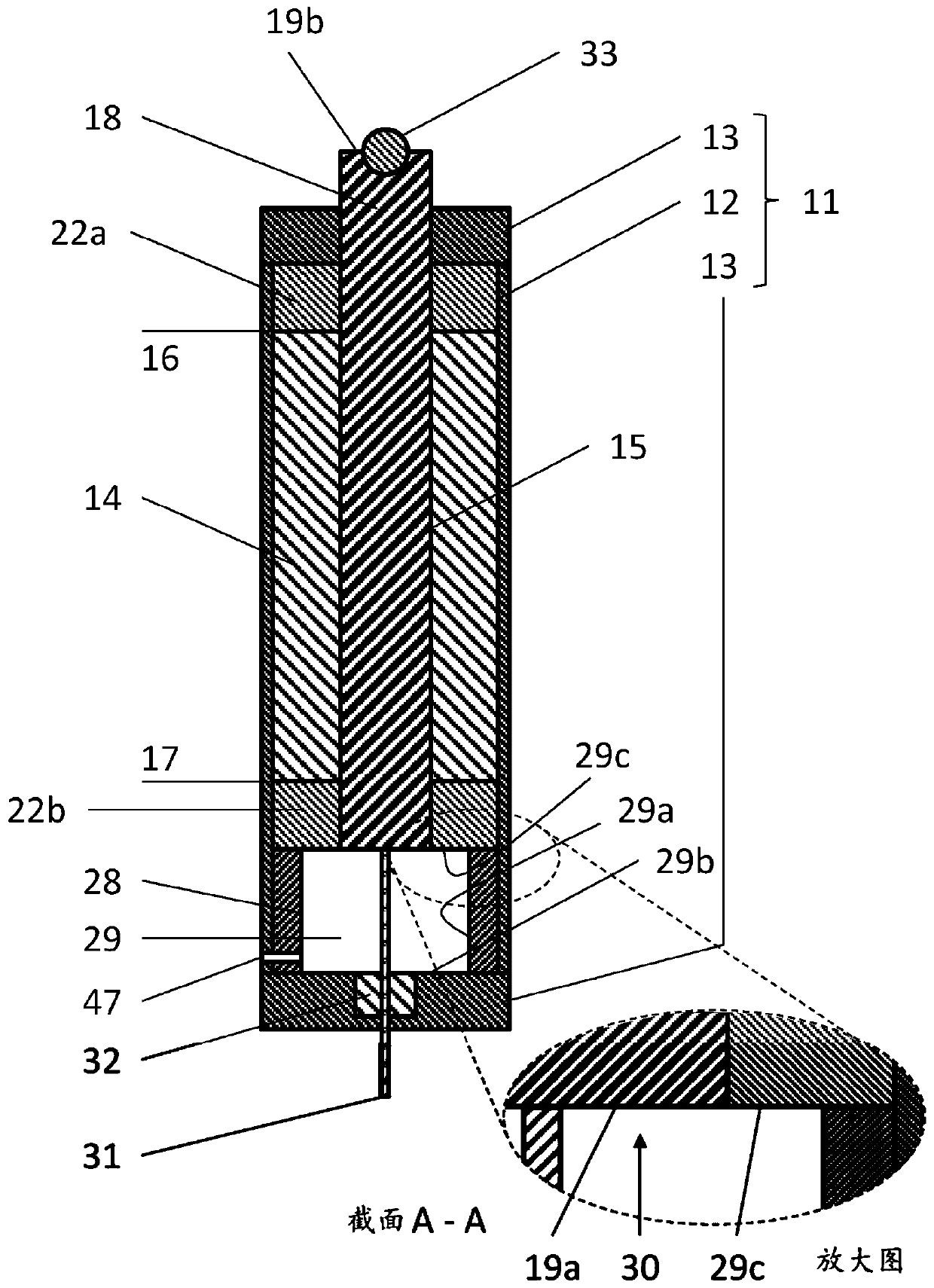

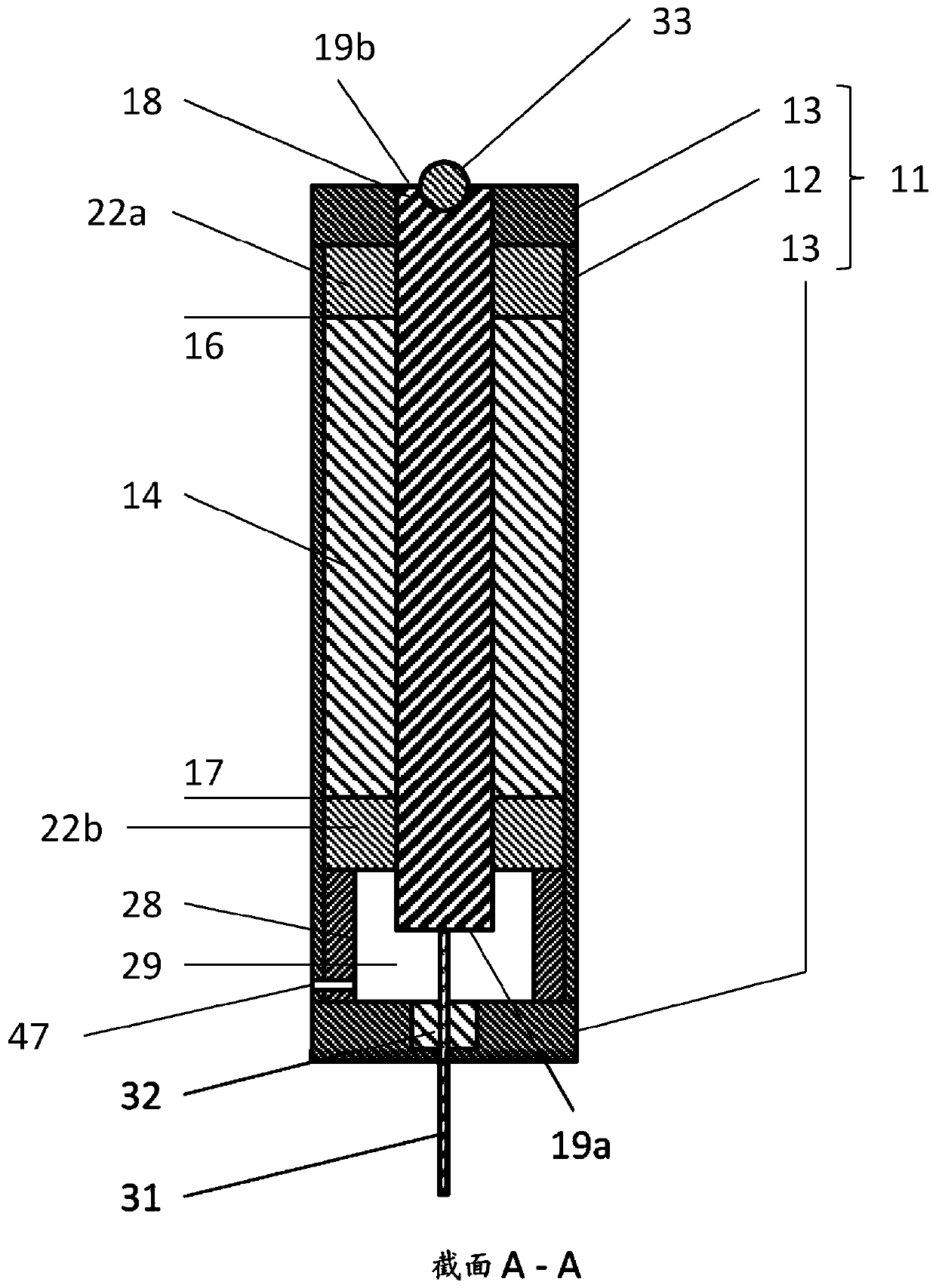

[0060] figure 1 is an external view of the first actuator 10 with an axis of motion 20 along which a translating body (shown later) moves and several planar positions for the other cross-sectional views.

[0061] figure 2 The actuator 10 is shown with a housing body 11 . The housing body 11 is formed by a typically cylindrical wall 12 and by end walls 13 defining a hollow interior. Inside holds a stator 14 which is generally a tubular linear motor stator with a cylindrical bore 15 extending axially from one end 16 to the other 17 of the stator. The translation body 18 is axially movable relative to the stator 14 . There is an external magnetic circuit air gap 21 between the translation body and the stator (see Figure 5 ). In this example embodiment, the housing, and thus the stator, is rigidly held, and the translating body 18 moves within the stator 14 .

[0062] A pair of hydrodynamic bearings 22a and 22b are provided, the upper bearing 22a defining one end of the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com