Waste gas treatment device for paper mill

A waste gas treatment device and paper mill technology, applied in gas treatment, air quality improvement, membrane technology, etc., can solve the problems of sewage odor, atmospheric environment and human health impact, living troubles of surrounding residents, etc., to solve the problem of odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

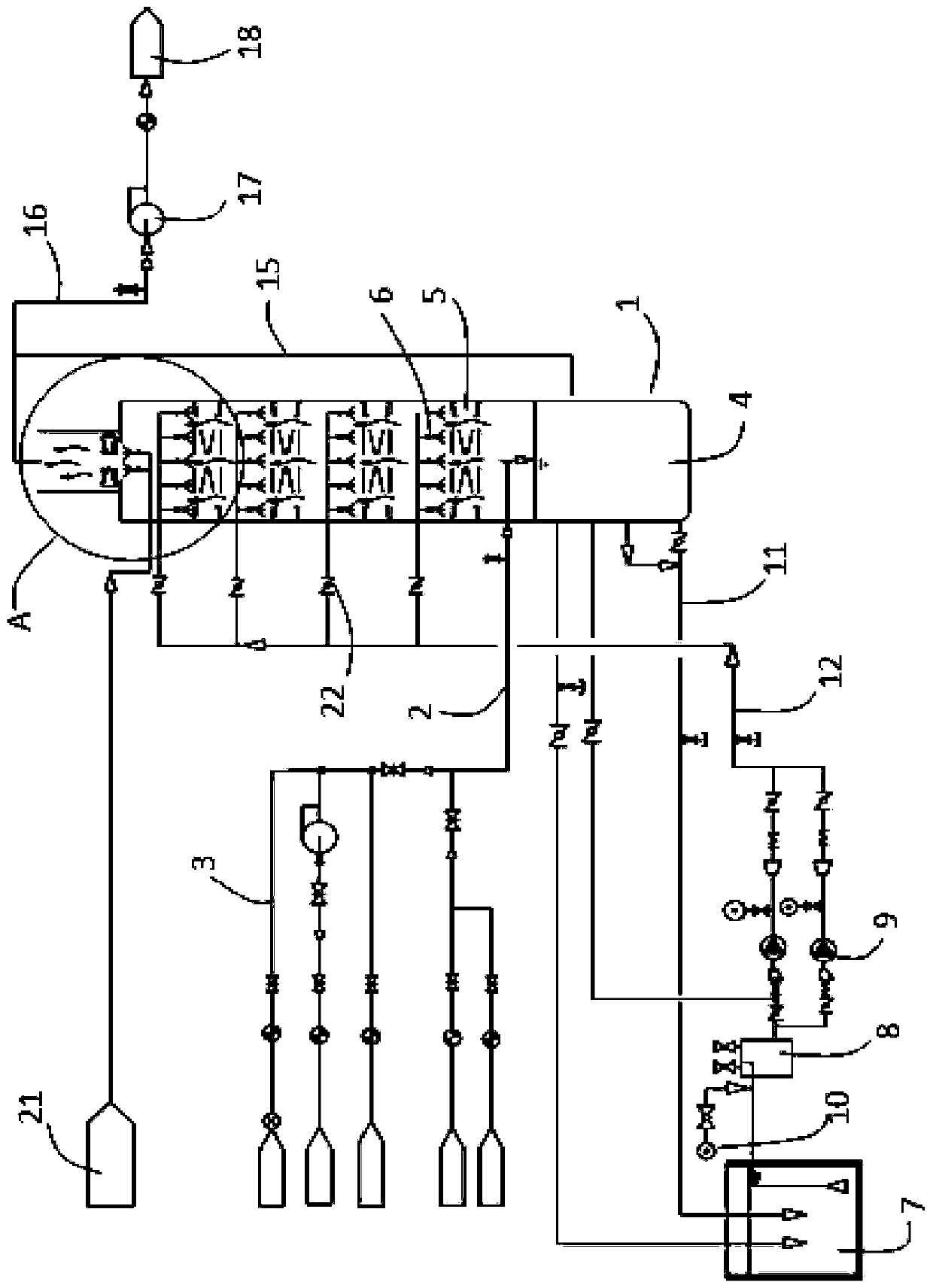

[0018] like figure 1 As shown, a waste gas treatment device for a paper mill includes a biological scrubber 1, one side of the biological scrubber 1 is provided with a waste gas transmission main pipe 2, and one end of the waste gas transmission main pipe 2 is connected to the biological scrubber 1, and the waste gas transmission main pipe 2 The other end is connected to several waste gas transmission single pipes 3 for collecting waste gas. The waste gas is generated from the pre-acidification tank, regulating tank, sludge thickening tank, primary sedimentation tank, etc. during the papermaking process. Each waste gas transmission A gate valve is provided on the single pipe 3 to regulate the internal exhaust gas transmission.

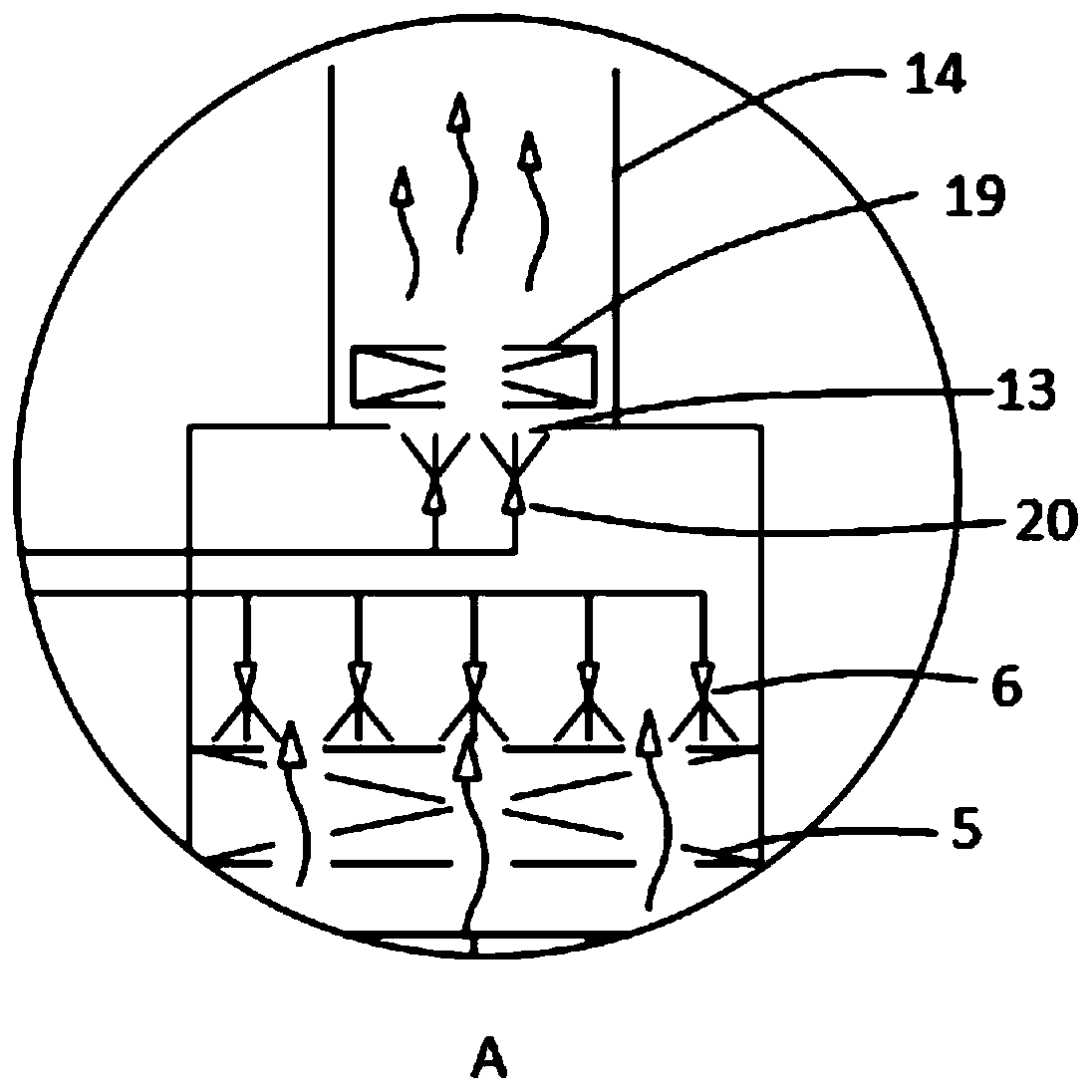

[0019] like figure 1 As shown, the biological scrubber 1 includes a liquid storage chamber 4 for holding circulating liquid, and above the liquid storage chamber 4, there are four levels of biological packing layers 5 equidistantly arranged, and above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com