System for treating refractory organic matters by combining microwave catalysis with advanced oxidation

A technology of refractory organic matter and advanced oxidation, which is applied in special compound water treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of slow reaction rate, low treatment efficiency and strict reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Adopt the method for processing refractory organic matter of the present invention to degrade papermaking wastewater, the COD of the refractory organic waste water to be treated is 780mg / L, and the dischargeable target value of COD is set at 50mg / L. The specific processing method is as follows:

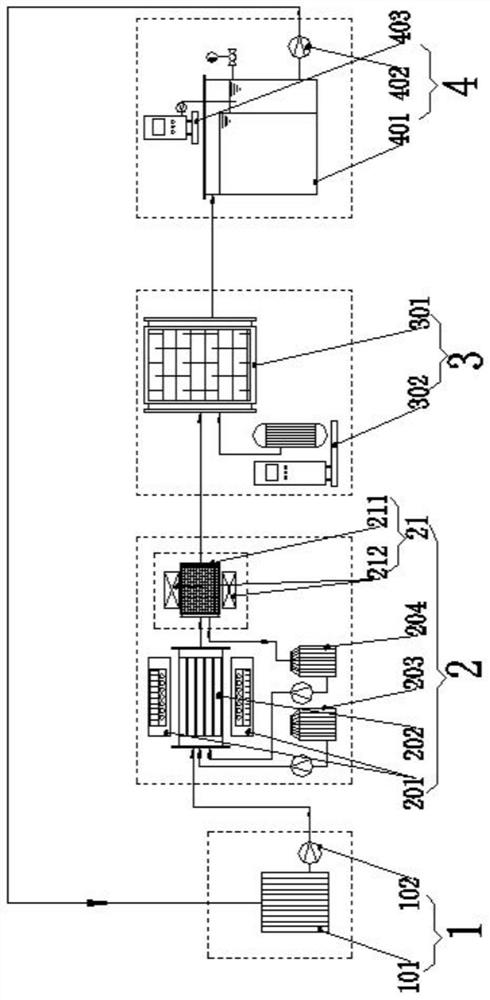

[0066] 1) The refractory organic waste water to be treated enters the water inlet system 1, is input by the circular water inlet device 101, and is delivered to the microwave catalytic unit 2 through the power unit 102.

[0067] 2) In the microwave catalytic unit 2, the wavelength of the electromagnetic wave generated by the microwave radiation device 201 is 10mm and the frequency is 800MHz; the added catalyst carrier is Fe 3 o 4 Nanoparticles, the catalyst active ingredient added is TiO 2 , the magnetic-gathering medium 211 is braided mesh-shaped magnetically conductive stainless steel, the filling rate of the magnetic-gathering medium 211 is 6%, the magnetic-gathering mediu...

Embodiment 2

[0081] Adopt the method for processing refractory organic matter of the present invention to carry out degradation treatment to printing and dyeing wastewater, the COD of the refractory organic matter wastewater to be treated is 1400mg / L, and the target value of setting COD dischargeable is 40mg / L. The specific processing method is as follows:

[0082] 1) The refractory organic waste water to be treated enters the water inlet system 1, is input by the square water inlet device 101, and is delivered to the microwave catalytic unit 2 through the power unit 102.

[0083] 2) In the microwave catalytic unit 2, the electromagnetic wave wavelength generated by the microwave radiation device 201 is 20 mm and the frequency is 2450 MHz, and the added catalyst carrier is Fe 3 o 4 Nanoparticles, the active components of the catalyst are CoO and TiO 2 , the magnetic gathering medium 211 is a vertical grid type magnetically conductive stainless steel, the filling rate of the magnetic gath...

Embodiment 3

[0089] Adopt the method for processing refractory organic matter of the present invention to carry out degradative treatment to coating waste water, the COD of the refractory organic matter waste water to be treated is 15000mg / L, sets the target value that COD can discharge 55mg / L. The specific processing method is as follows:

[0090] 1) The refractory organic waste water to be treated enters the water inlet system 1, is input by the water inlet device 101 of the circular mesh shape, and is delivered to the microwave catalytic unit 2 through the power unit 102.

[0091] 2) In the microwave catalytic unit 2, the wavelength of the electromagnetic wave generated by the microwave radiation device 201 is 30mm and the frequency is 4700MHz; the added catalyst carrier is Fe 3 o 4 and FeO nanoparticles, the catalyst active ingredients added are CoO and Al 2 o 3 , the magnetic gathering medium 211 is a triangular tooth plate iron-cobalt alloy, the filling rate of the magnetic gather...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com