A method for making yin and yang matching true color separation jewelry

A production method and color separation technology, applied in clothing, jewelry, applications, etc., can solve problems such as unfavorable metal-to-metal fusion, difficult color division, and melting of joints, and achieve low cost, clear color separation contrast, and eliminate oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

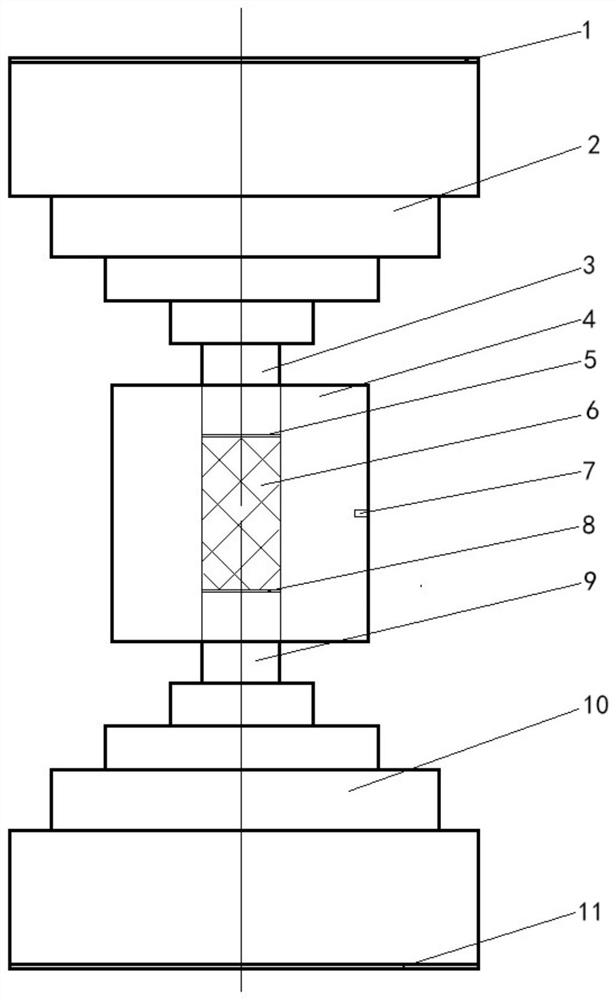

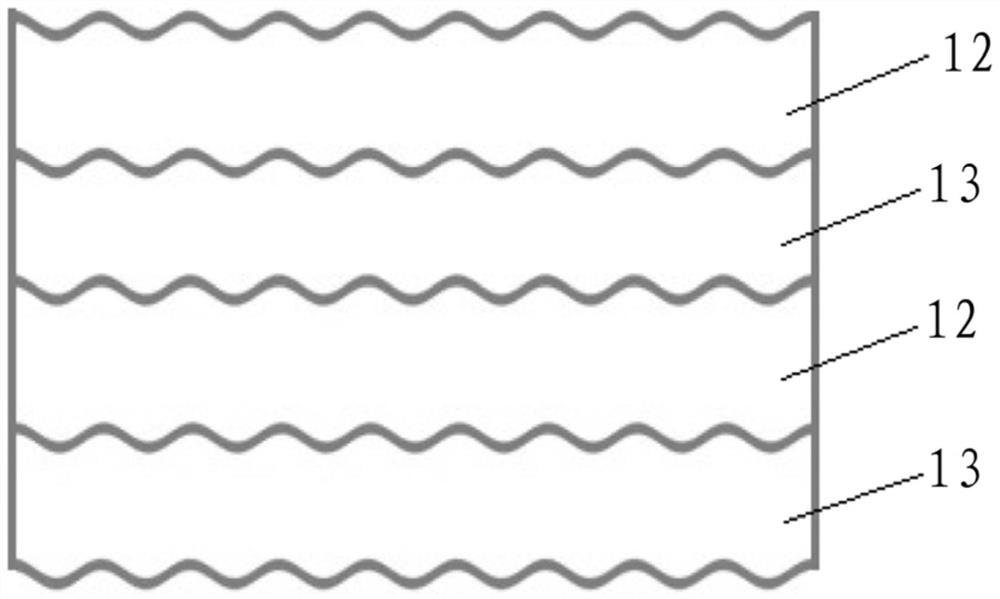

[0037] As a method for making wavy yin and yang matching true color separation jewelry according to the present invention, the method includes the following steps:

[0038] (1) Dry the white copper and high copper alloy powder with color contrast at 80°C for 1 hour, and the particle size of the metal powder is 350 mesh;

[0039](2) Put the lower pressure head with a wavy working surface in the bucket cup, weigh the required weight of white copper metal powder, put it into it and level it, then put it into the upper pressure head with a wavy working surface, and use Compact it with a desktop hydraulic machine, the pressure is 11MPa, and the holding time is 70 seconds. Take out the upper indenter, then weigh the high copper alloy powder of the required weight, put it into the sweeper, and then put it into the upper indenter to compact it. Then fill and compact a layer of white copper powder and high-copper powder according to the above method, and compact them in stages to obtai...

Embodiment 2

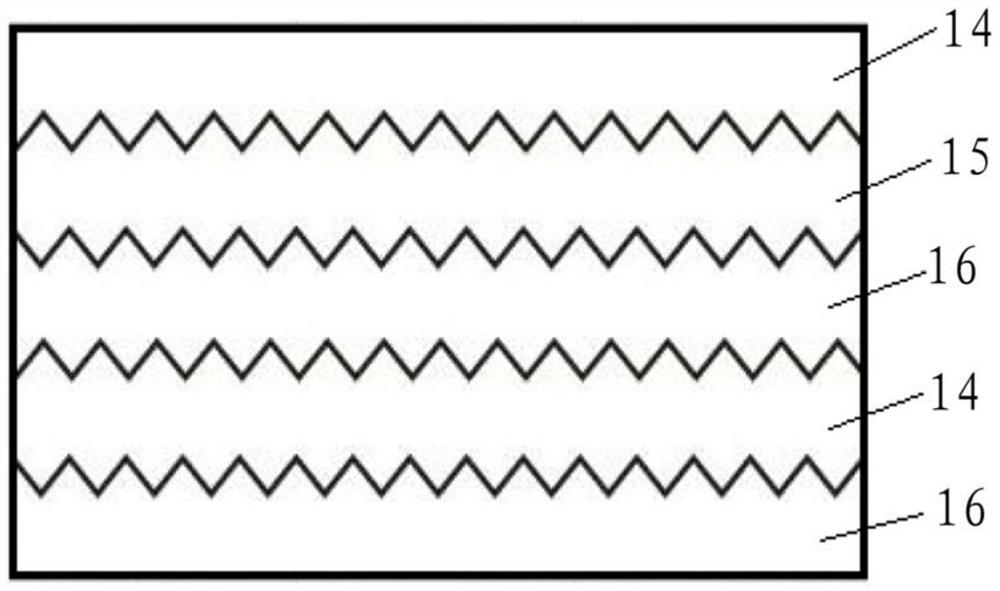

[0045] As a method for making zigzag yin and yang matching true color separation jewelry according to the present invention, the method includes the following steps:

[0046] (1) Dry brass, red copper, and white copper metal powders with color contrast at 50°C for 2 hours, and the particle size of the metal powders is 300 mesh;

[0047] (2) Put the lower pressing head with zigzag working surface in the barrel cup, weigh the required weight of brass powder, put it into it and level it, then put it into the upper pressing head with zigzag working surface, and use Compact it with a desktop hydraulic machine, the pressure is 10MPa, and the pressure holding time is 80 seconds. Take out the upper indenter, then weigh the copper powder of the required weight, put it into the upper indenter with a sawtooth-shaped working surface after sweeping it. It is compacted, and then weigh the white copper powder of the required weight, put it into the sweeper, and then put it into the zigzag up...

Embodiment 3

[0053] As a method for making semicircular yin and yang matching true color separation jewelry according to the present invention, the method includes the following steps:

[0054] (1) Dry stainless steel and bronze metal powders with color contrast at 65°C for 1.5 hours, and the particle size of the metal powders is 350 mesh;

[0055] (2) Put the lower pressure head with a flat working surface in the barrel cup, weigh the stainless steel powder of the required weight, put it into it and sweep it, then put it into the upper pressure head with a semicircular working surface, and use Compact it with a desktop hydraulic machine, the pressure is 10MPa, and the holding time is 80 seconds. Take out the upper indenter, then weigh the bronze powder of the required weight, put it into the upper indenter with a semicircular working surface Compact it, weigh the stainless steel powder with the required weight, put it into the sweeper, and then put it into the upper pressure head with a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com