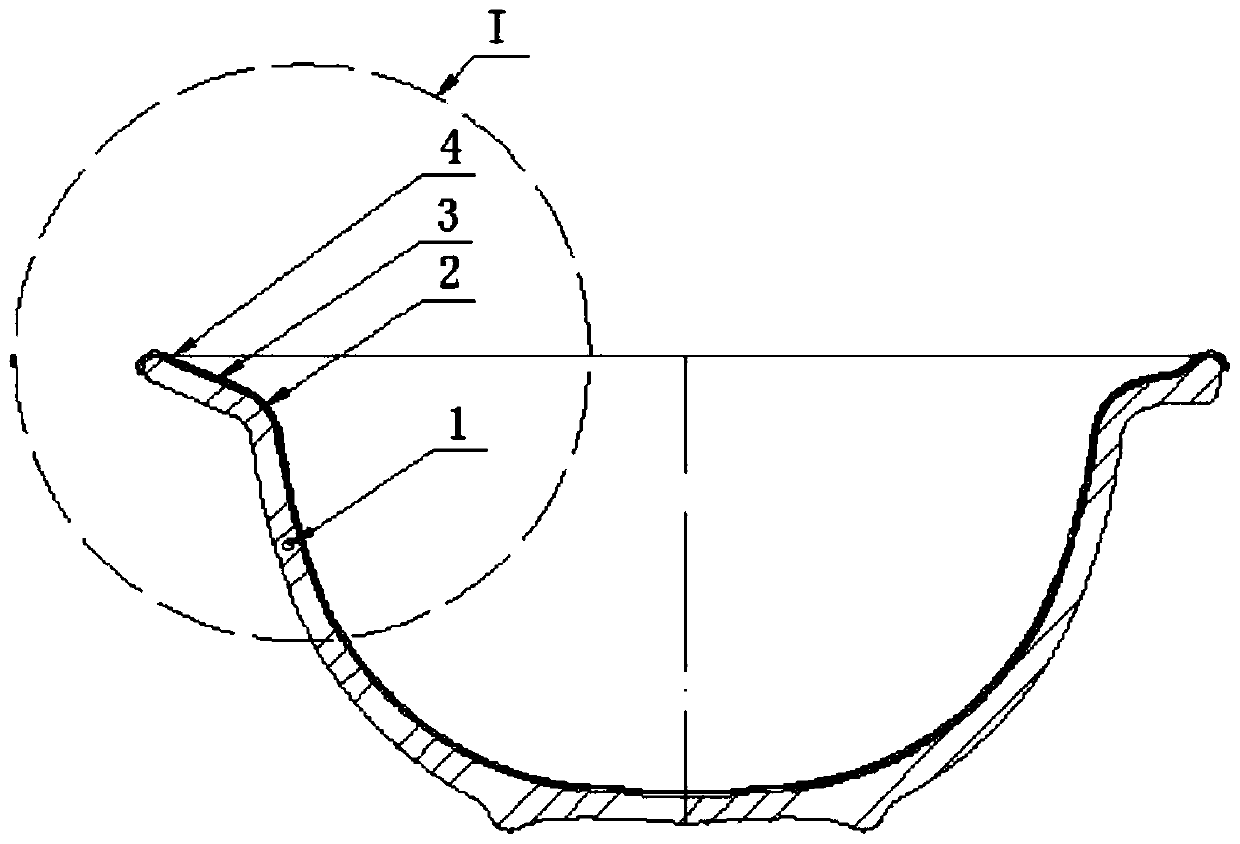

Glassware coated with non-sticky coating layer, and preparation technology thereof

A technology of non-stick coating and glassware, applied in the direction of coating, epoxy resin coating, etc., can solve the problems of inconvenient processing of vessels, large pollution in the processing process, and food sticking on the inner surface, so as to increase useful new Functional, easy to use, labor-saving, and easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

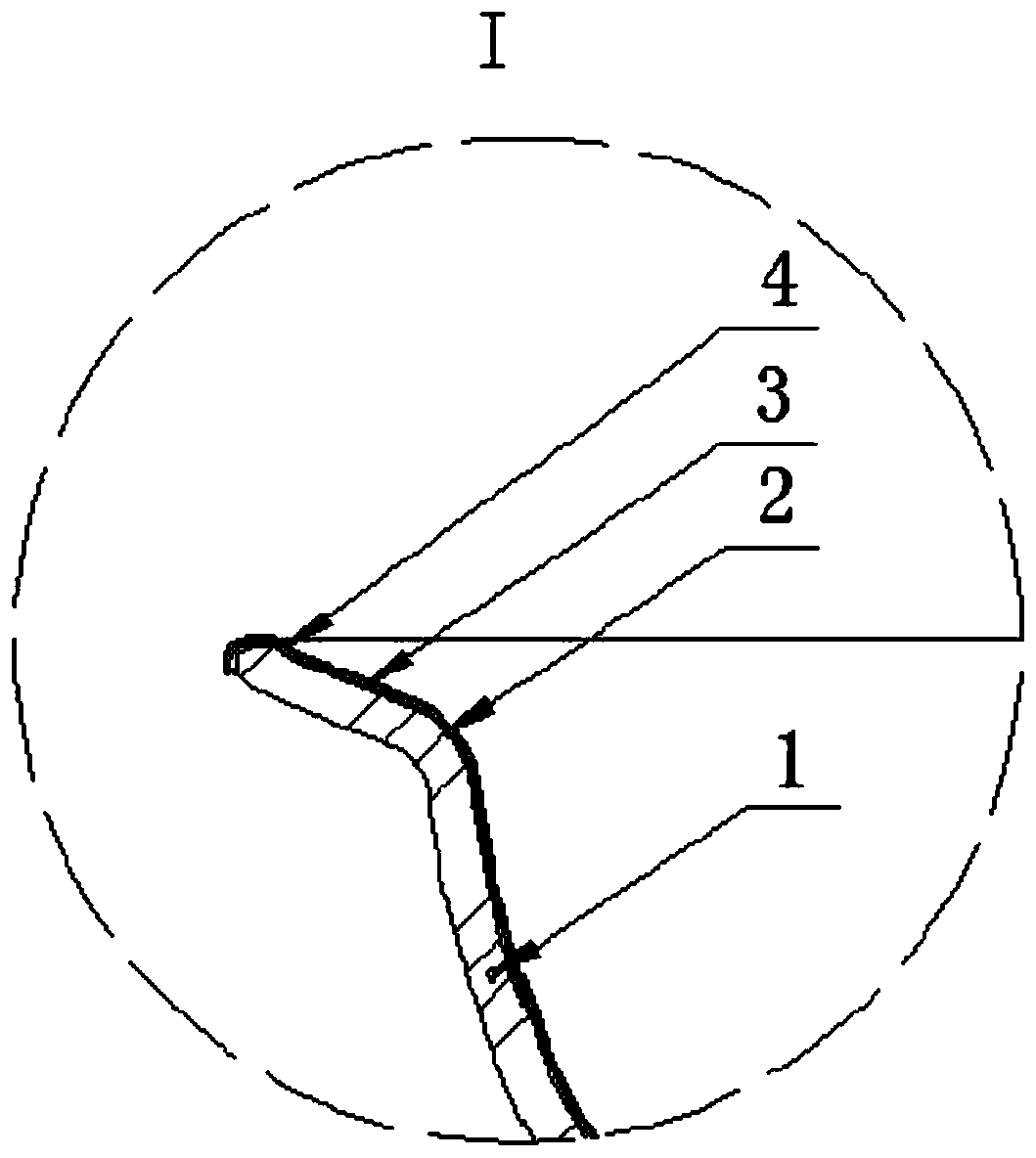

[0062] The present embodiment provides a glassware coated with a non-stick coating, which is prepared through the following steps:

[0063] (1) Pretreatment of the inner surface of the glassware: degrease the inner surface of the glassware, wash it with hot water and wash it with pure water in order to remove impurities on the inner surface, and dry the inner surface with cold air after cleaning;

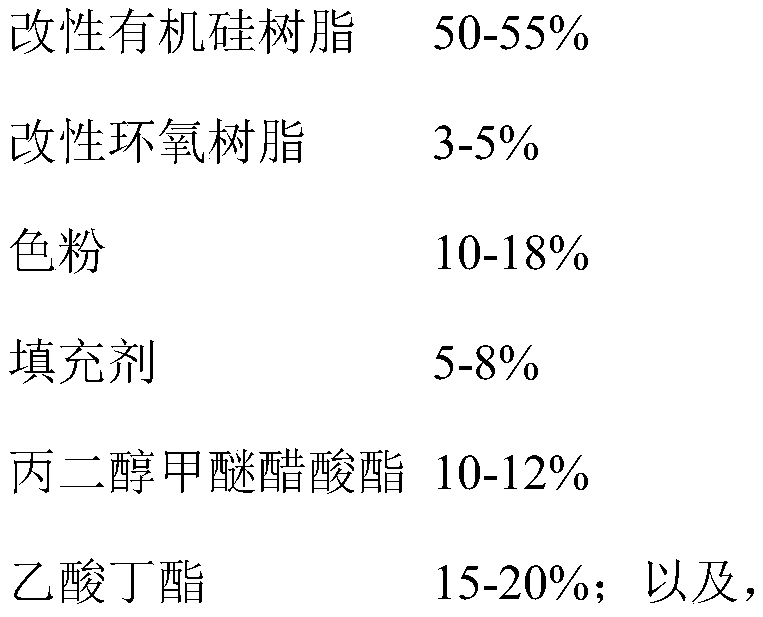

[0064] (2) Adhesive layer spraying: configure the adhesive layer raw materials according to the following mass percentages: 50% modified epoxy resin, 19% amino resin, 1% leveling agent, 5% thickener, 10% propylene glycol methyl ether acetate , 15% butyl acetate, after batching, put modified epoxy resin, amino resin, propylene glycol methyl ether acetate, and butyl acetate into the grinder for grinding, and the grinding fineness is below 10 μm; then add leveling agent, thickener After the agent is uniformly dispersed by a homogenizer, the viscosity is adjusted, and after being filter...

Embodiment 2

[0069] The borosilicate glassware coated with non-stick coating provided in this embodiment is prepared through the following steps:

[0070] (1) Pretreatment of the inner surface of the high borosilicate glassware: the inner surface of the high borosilicate glassware is degreased, washed with hot water and washed with pure water in sequence, and the inner surface is dried with cold air after cleaning;

[0071] (2) Adhesive layer spraying: Configure the adhesive layer raw materials according to the following mass percentages: 40% modified epoxy resin, 20% amino resin, 2% leveling agent, 8% thickener, 12% propylene glycol methyl ether acetate , 18% butyl acetate, after mixing and stirring evenly, spray on the inner surface of high borosilicate glassware, the thickness of spraying is 8μm;

[0072] (3) Bottom spraying: configure the bottom raw materials according to the following mass percentages: 50% modified silicone resin, 5% modified epoxy resin, 10% toner, 5% filler, 10% pro...

Embodiment 3

[0076] The borosilicate glassware coated with non-stick coating provided in this embodiment is prepared through the following steps:

[0077] (1) Pretreatment of the inner surface of the high borosilicate glassware: the inner surface of the high borosilicate glassware is subjected to degreasing cleaning, hot water cleaning and pure water cleaning in sequence, and the inner surface is dried after cleaning;

[0078] (2) Adhesive layer spraying: configure the adhesive layer raw materials according to the following mass percentages: 44% modified epoxy resin, 15% amino resin, 1% leveling agent, 8% thickener, 12% propylene glycol methyl ether acetate , 20% butyl acetate, after mixing and stirring evenly, spray on the inner surface of high borosilicate glassware, the thickness of spraying is 7μm;

[0079] (3) Bottom spraying: configure the bottom raw materials according to the following mass percentages: 55% modified silicone resin, 3% modified epoxy resin, 11% toner, 5% filler, 10% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com