Smelting furnace capable of automatically adjusting temperature

A smelting furnace and automatic technology, applied in the field of smelting furnaces, can solve problems such as CO leakage, CO waste, and environmental pollution, and achieve the effects of avoiding waste, protecting the environment, and realizing collection and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

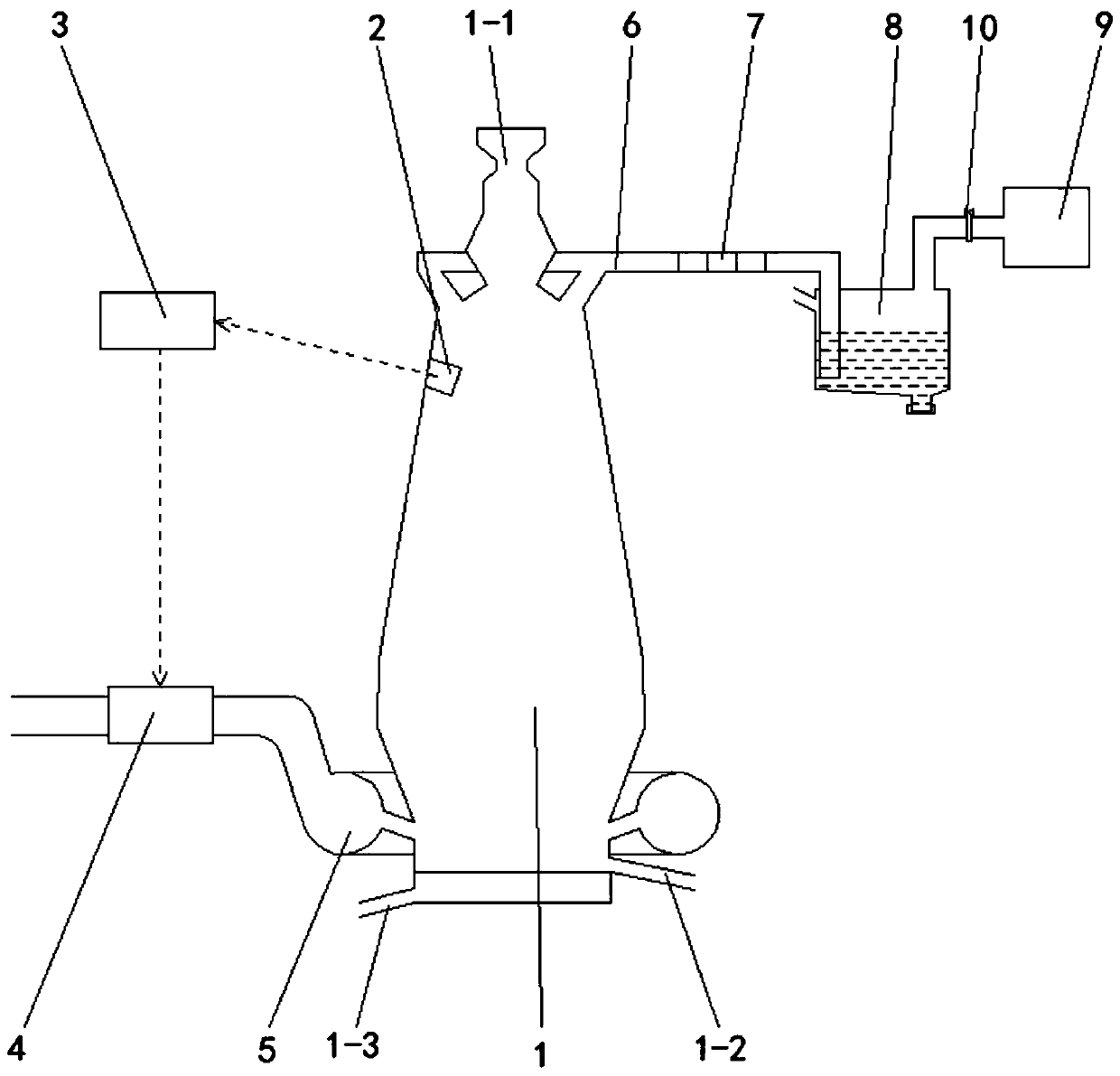

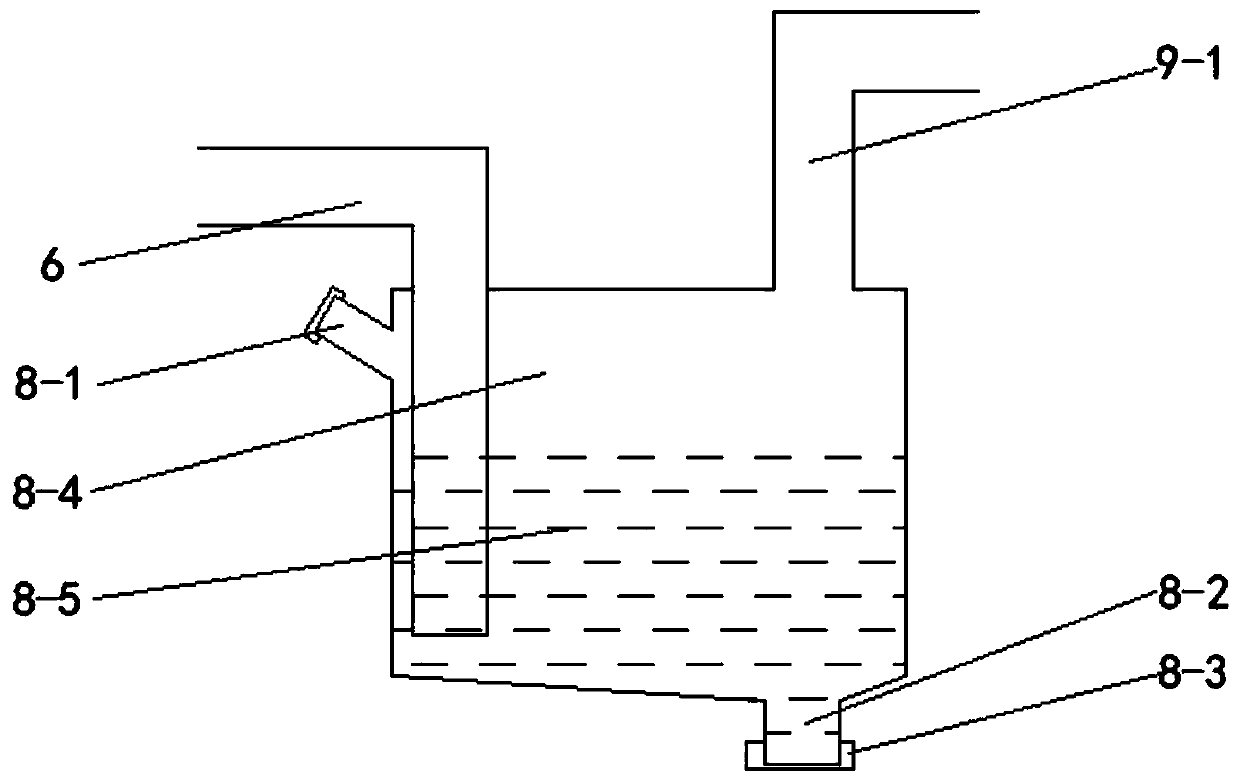

[0014] Specific implementation one: as Figure 1 to Figure 3 As shown, the present invention discloses a smelting furnace with automatic temperature adjustment, including a furnace body 1, a hot air pipe 5, a temperature sensor 2, a temperature control system 3, an automatic flow valve 4, a dust suction mechanism 7, a CO separation device 8, The CO storage device 9 and the flue gas pipe 6 are arranged in communication with the furnace body 1 and the hot air pipe 5 and the flue gas pipe 6. A temperature sensor 2 is fixed inside the furnace body 1, and the output end of the temperature sensor 2 It is connected with the input end of the temperature control system 3, and the output end of the temperature control system 3 is connected with the input end of the automatic flow valve 4. The automatic flow valve 4 is arranged on the hot air pipe 5; the flue gas pipe 6 is provided with a dust suction mechanism 7 and the outlet end is arranged in communication with the inlet end of the C...

specific Embodiment approach 2

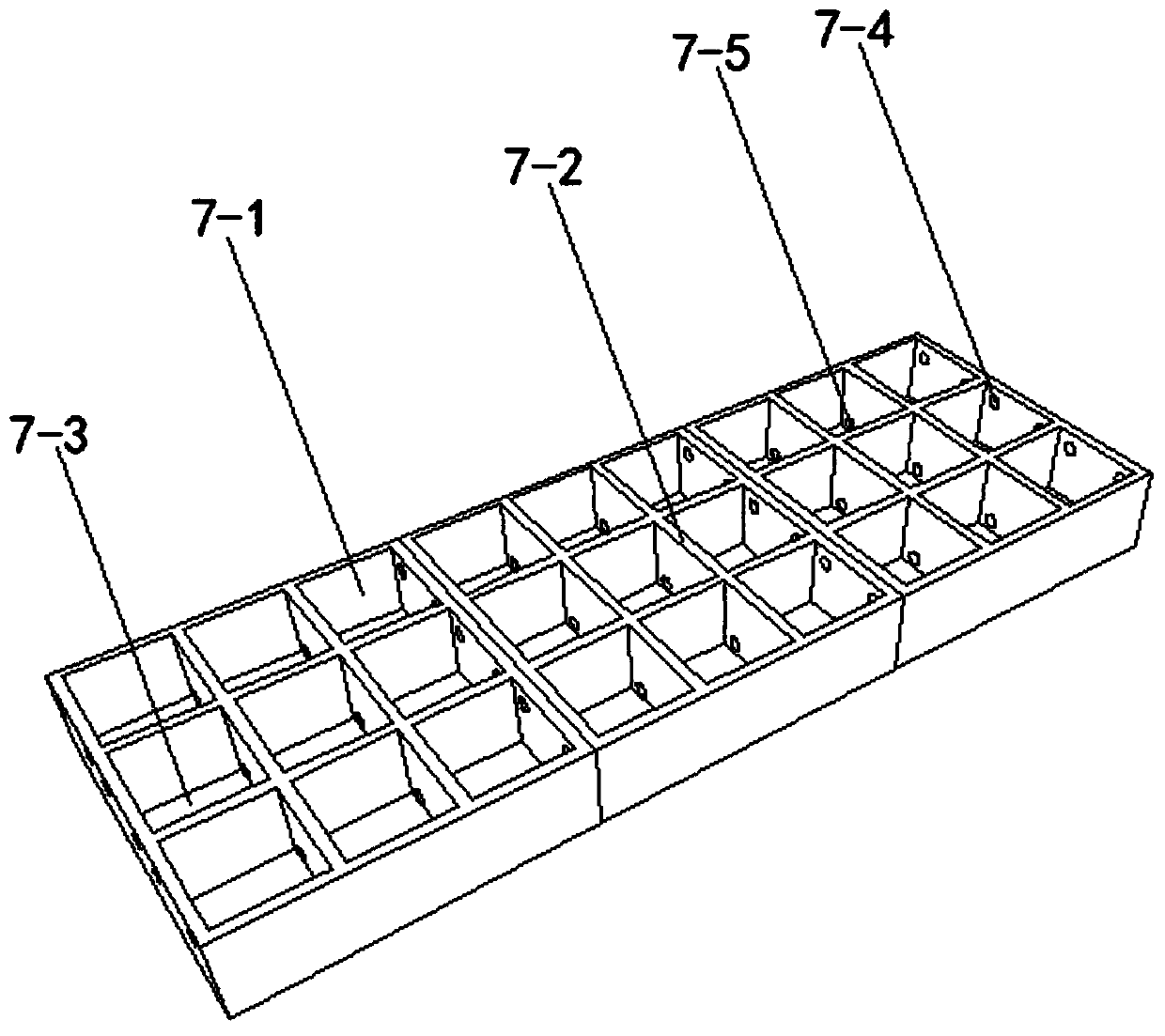

[0015] Specific implementation two: as figure 2 As shown, this embodiment is a further description of the specific embodiment 1. The dust suction mechanism 7 includes a vibration motor and a plurality (three) of electrostatic adsorption boxes 7-1. The plurality (three) of electrostatic adsorption boxes 7-1. The boxes 7-1 are plug-connected in close proximity to each other along the axial direction of the flue gas pipe 6. The plug-in arrangement facilitates the separation of a plurality of electrostatic adsorption boxes 7-1 from each other for replacement during use. One of the electrostatic adsorption boxes 7-1 It is fixedly connected with the output shaft of the vibration motor, and the inner cavity of each electrostatic adsorption box 7-1 is divided into a plurality of adsorption chambers 7-3 by a plurality of horizontal and vertical partitions 7-2, preferably equally divided, Each of the adsorption chambers 7-3 is provided with a triboelectric nanogenerator and filled with...

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment is a further description of Embodiment 2. The plurality of electrostatic adsorption boxes 7-1 are made of insulating materials, and the plurality of separators 7-2 are made of metal materials. to make.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com