Preparation method of nano-cobalt-supported nitrogen-doped three-dimensional porous carbon and its application in lithium-sulfur batteries

A three-dimensional porous, nano-cobalt technology, applied in nanotechnology, battery electrodes, nanotechnology, etc., can solve the problems of lack of mesopores, macroporous structure, low yield, difficulty in accommodating the volume change of sulfur cathodes, etc. Quantity, increase yield, and increase the effect of adsorbing polysulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention proposes a preparation method of nitrogen-doped three-dimensional porous carbon supported by nano-cobalt, comprising the following steps:

[0026] (1) adding inorganic nanospheres to methanol for ultrasonic dispersion, then adding cobalt salt and stirring to dissolve, then adding 2-methylimidazole methanol solution to obtain a precursor solution;

[0027] Preferably, the concentration of inorganic nanospheres in the precursor solution is 5-50 g / L; the concentration of cobalt salt in the precursor solution is 0.01-0.1 mol / L; the cobalt salt and 2-methylimidazole The molar ratio of 1: (0.5 ~ 10) to form the ZIF67 precursor. The number of mesopores and macropores is controlled by controlling the amount of cobalt salt and inorganic nanospheres added, and the wall thickness of the three-dimensional porous carbon in the product is controlled by controlling the ratio of cobalt salt and inorganic nanospheres.

[0028] Preferably, the inorganic nanospheres...

Embodiment 1

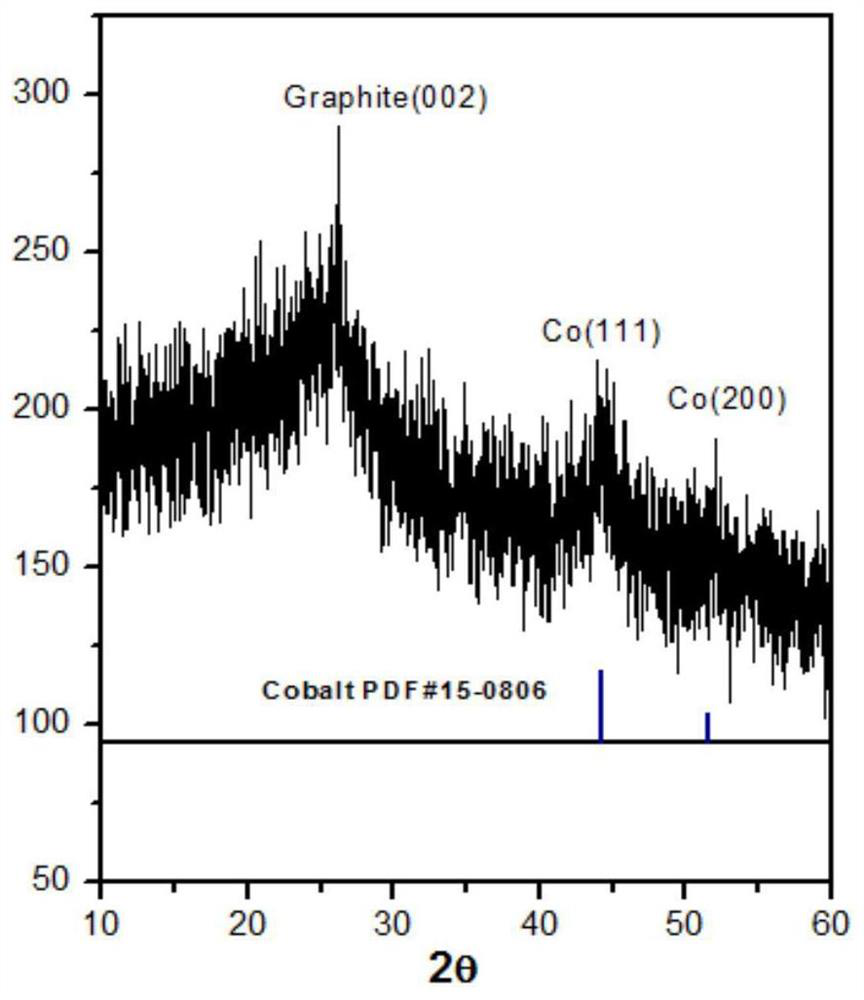

[0041] This embodiment provides a method for preparing nano-cobalt-supported nitrogen-doped three-dimensional porous carbon, comprising the following steps:

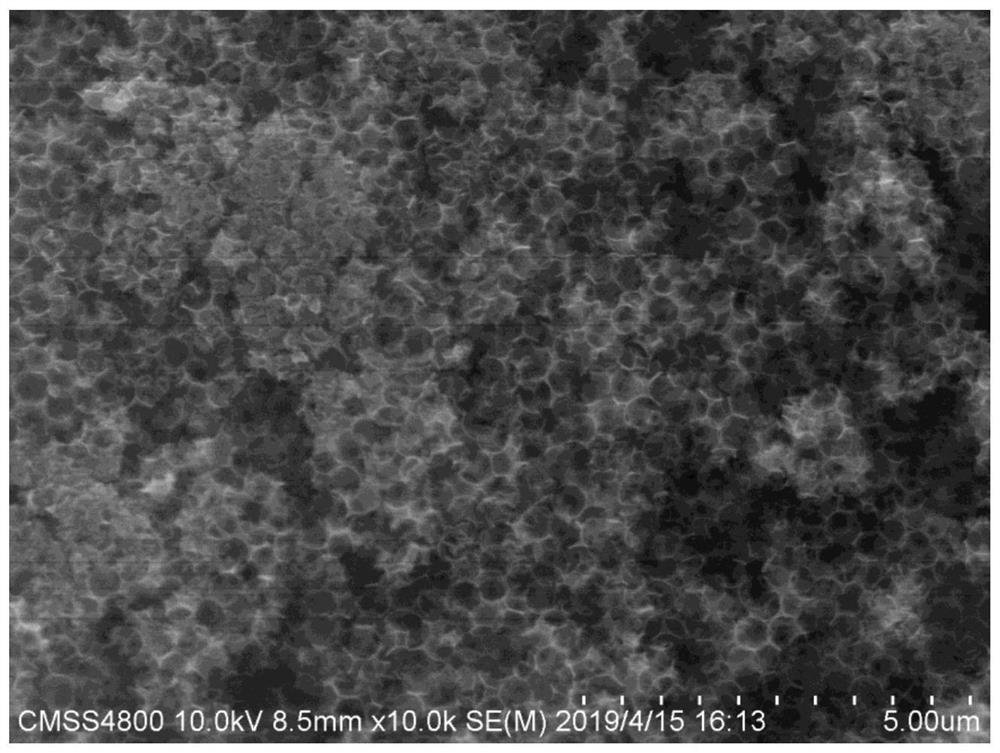

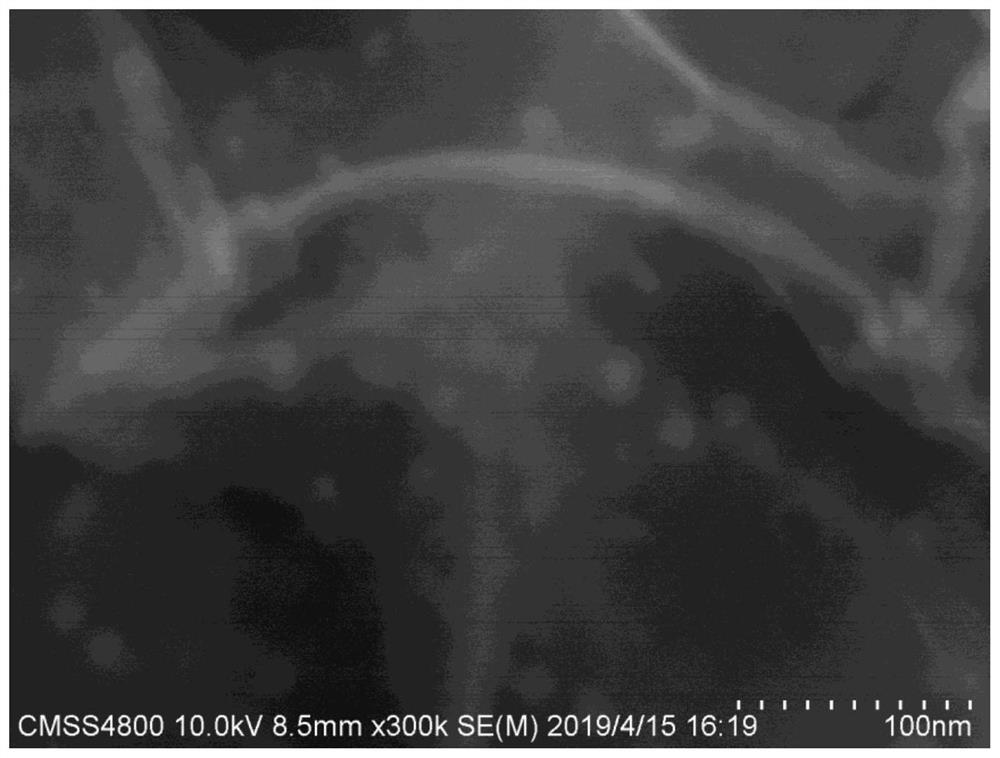

[0042] (1) Add 15ml tetraethyl orthosilicate to a mixed solvent composed of 10ml ammonia water, 200ml ethanol, and 100ml water under magnetic stirring, stir at 30°C for 2h, filter, wash and dry the resulting product to obtain a particle size of 300nm Silica nanosphere powder left and right.

[0043] (2) get the 3.0g white SiO obtained in step (1) 2 The nanosphere powder was ultrasonically dispersed in 100ml methanol for 2h, and then 0.8g Co(NO 3 ) 2 Stir to dissolve, then add 100ml of methanol solution containing 1.0g of 2-methylimidazole to obtain a precursor solution.

[0044] (3) The precursor solution was stirred and reacted at 30°C for 1 hour, and then stirred and evaporated to dryness at 80°C to obtain gray-purple precursor powder;

[0045] (4) Place the gray-purple precursor powder in a tube furnace under high...

Embodiment 2

[0054] This embodiment provides a method for preparing nano-cobalt-supported nitrogen-doped three-dimensional porous carbon, comprising the following steps:

[0055] (1) Add 15ml of tetraethyl orthosilicate to a mixed solvent consisting of 5ml of ammonia water, 200ml of ethanol, and 20ml of water under magnetic stirring, stir at 30°C for 2 hours, filter, wash and dry the resulting product to obtain a particle size of 100nm Silica nanosphere powder left and right.

[0056] (2) get the SiO of 3.0g that step (1) obtains 2 The nanosphere powder was ultrasonically dispersed in 100ml methanol for 2h, and then 0.8g Co(NO 3 ) 2 Stir to dissolve, and then add 100 ml of methanol solution containing 1.0 g of 2-methylimidazole to obtain a precursor reaction solution.

[0057] (3) The precursor reaction solution obtained in step (2) was stirred and reacted at 40°C for 0.5h, and then stirred and evaporated to dryness at 90°C to obtain gray-purple precursor powder;

[0058] (4) Place the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com