Plasma jet safety grounding device

A safe grounding and plasma technology, applied in the direction of connecting contact materials, etc., to achieve reliable insulation, ensure grounding safety, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

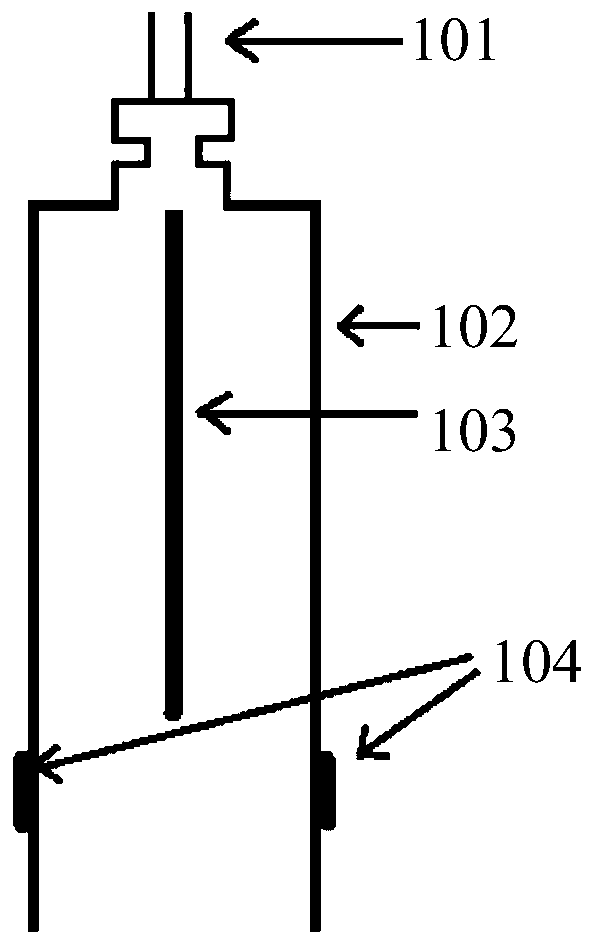

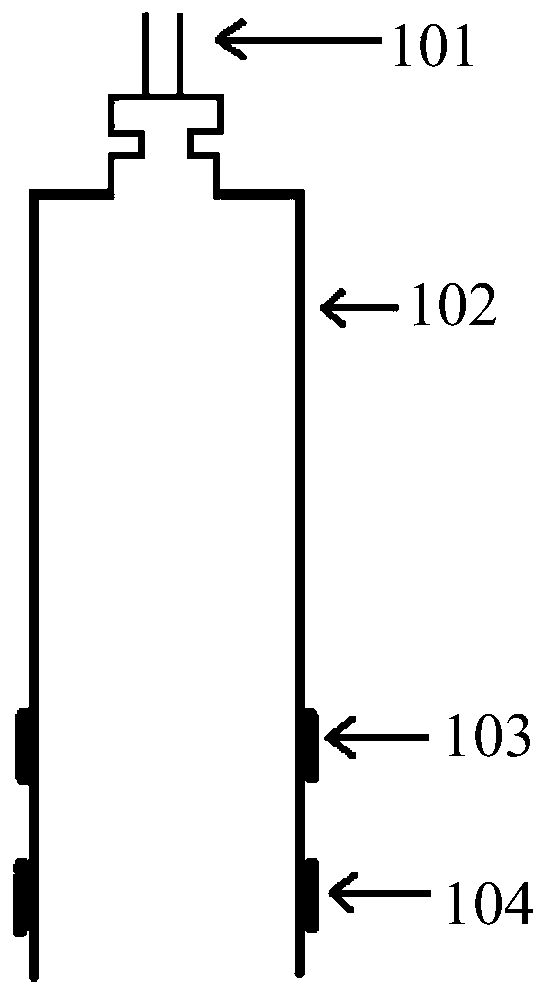

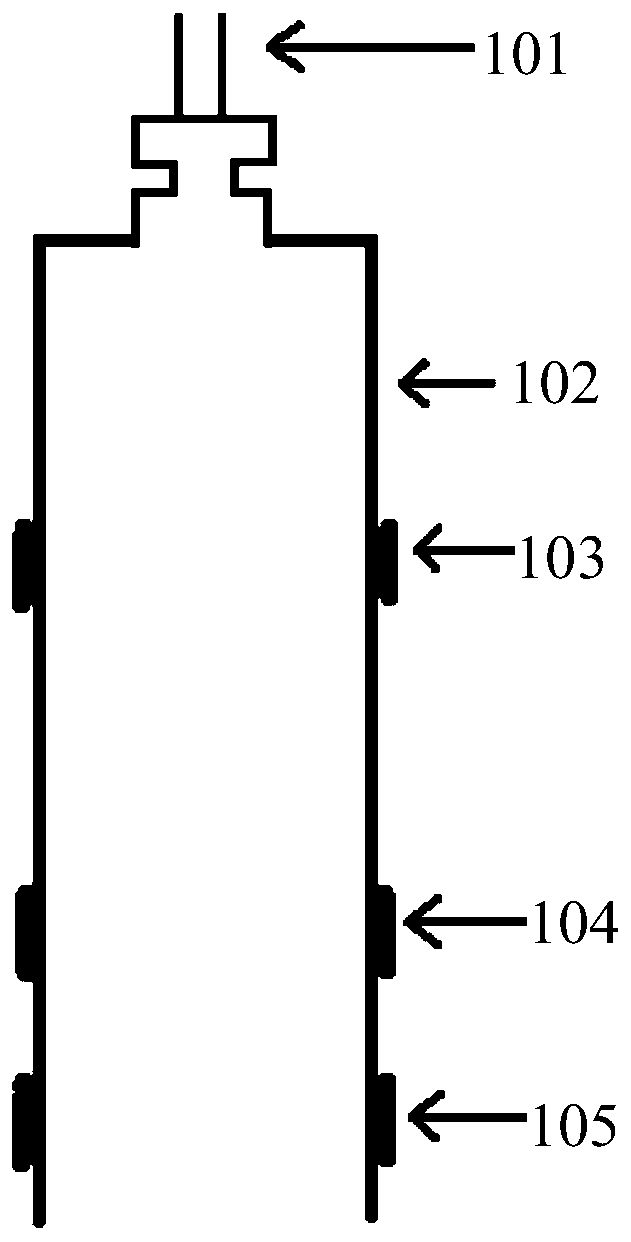

[0044] Such as Figure 4 , Figure 5 As shown, the plasma jet safety grounding device includes a first insulating sleeve 1 and a second insulating sleeve 2; the first insulating sleeve forms a tight package on the quartz glass tube, and the inner side of the first insulating sleeve corresponds to Each ring electrode on the outer wall of the quartz glass tube 102 has a concave structure formed as an air gap 1a left by the ring electrode. The concave structure also has a radially penetrating channel 1b for wiring; second insulation The sleeve is sleeved and fixed on the outside of the first insulating sleeve, and there is a gap between the sleeve and the first insulating sleeve.

[0045] The parts of the quartz glass tube adjacent to the upper and lower ends of the ring electrode are tightly wrapped by the first insulating sleeve. The thickness of the ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com