Multi-dripper UV photocuring water-based capsule production equipment

A production equipment, light curing technology, applied in microcapsule preparation, microsphere preparation, tobacco and other directions, can solve the problem of complete loss of water dispersion of capsules, cannot limit the difference of drop-making capsules from the root, and cannot become a regular spherical shape, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1: the water-based capsule production equipment of multi-dropper UV photocuring of the present invention

[0068] The implementation mode of this embodiment is as follows:

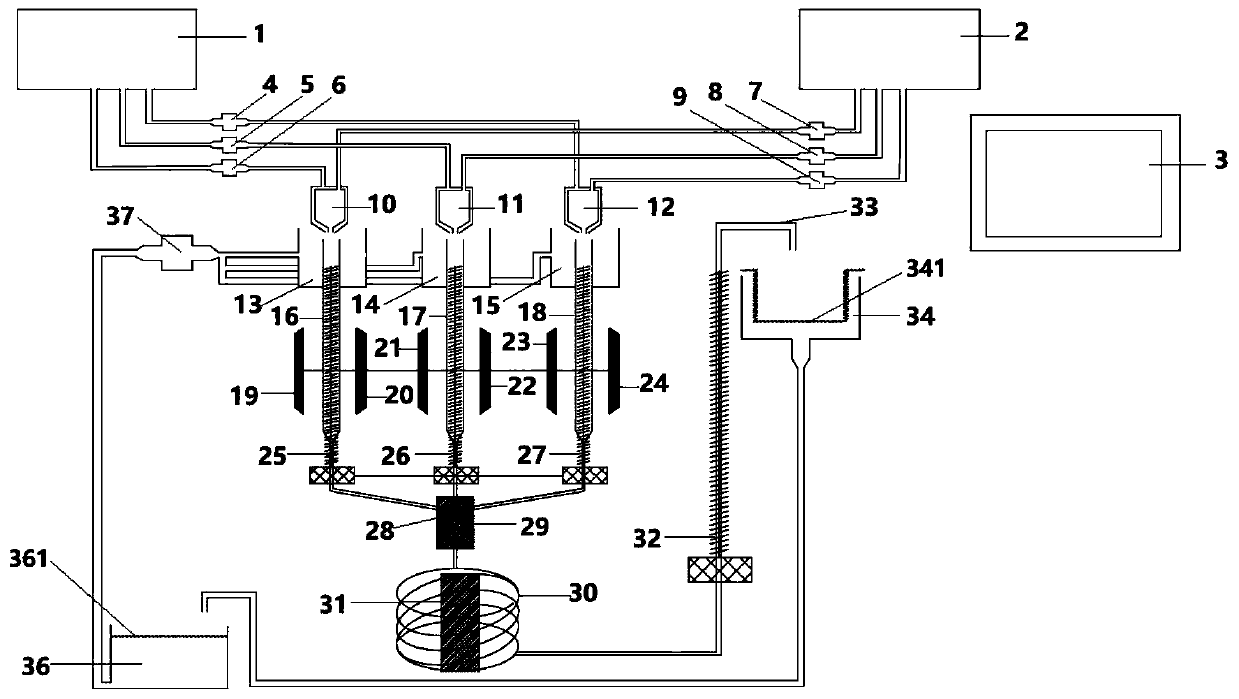

[0069] The UV light-cured water-based capsule production equipment includes a core liquid tank 2 and a UV glue tank 1, and the production equipment is composed of a feed system A, a molding system B, a circulation system C and a control system D; wherein:

[0070] Feeding system A consists of core liquid tank 1, UV glue liquid tank 2, core liquid pump A 4, core liquid pump B 5, core liquid pump C 6, UV glue pump A7, UV glue pump B 8, UV glue Pump C 9, capsule dripper A 12, capsule dripper B 11 and capsule dripper C 10; core liquid tank 1 is connected to capsule dripper A through core liquid pump A 4, core liquid pump B5, core liquid pump C 6 12. The capsule dripper B 11 is connected to the corresponding interface of the capsule dripper C 10; the UV glue tank 2 is connected to the capsule d...

Embodiment 2

[0081] Embodiment 2: the water-based capsule production equipment of multi-dropper UV photocuring of the present invention

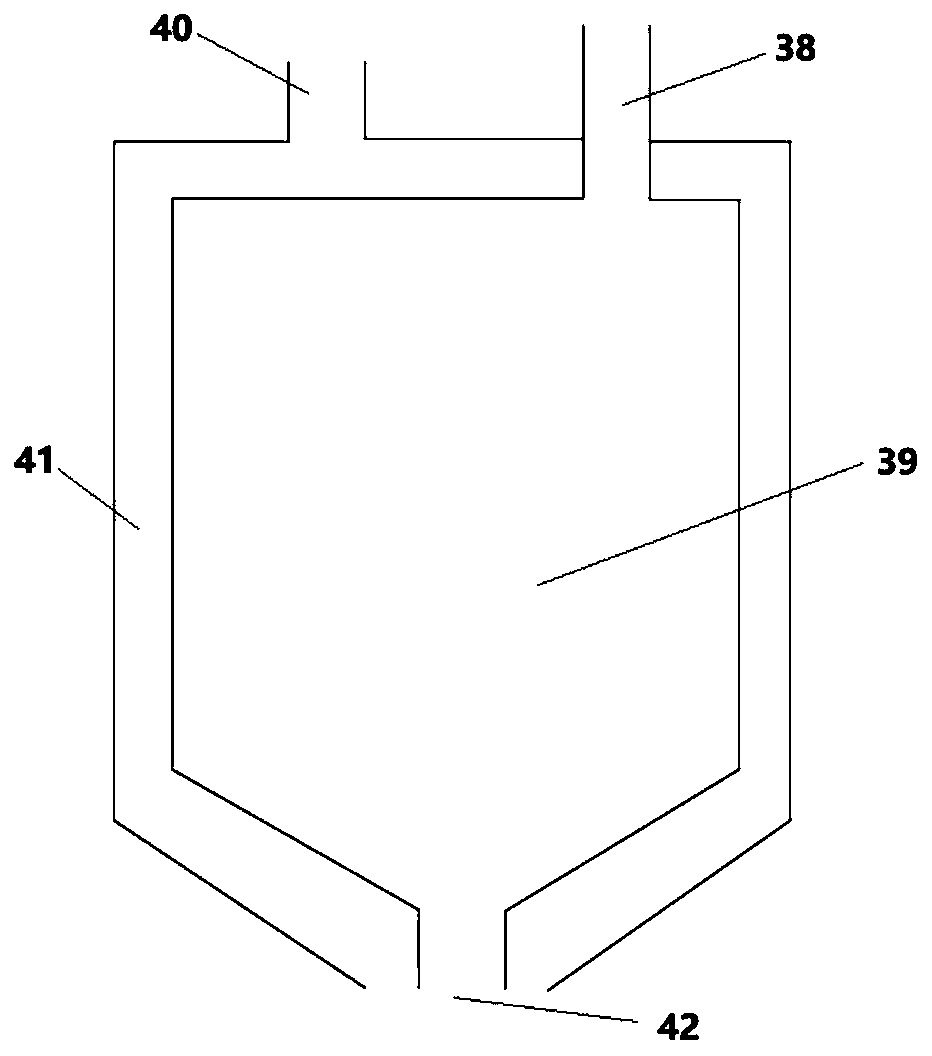

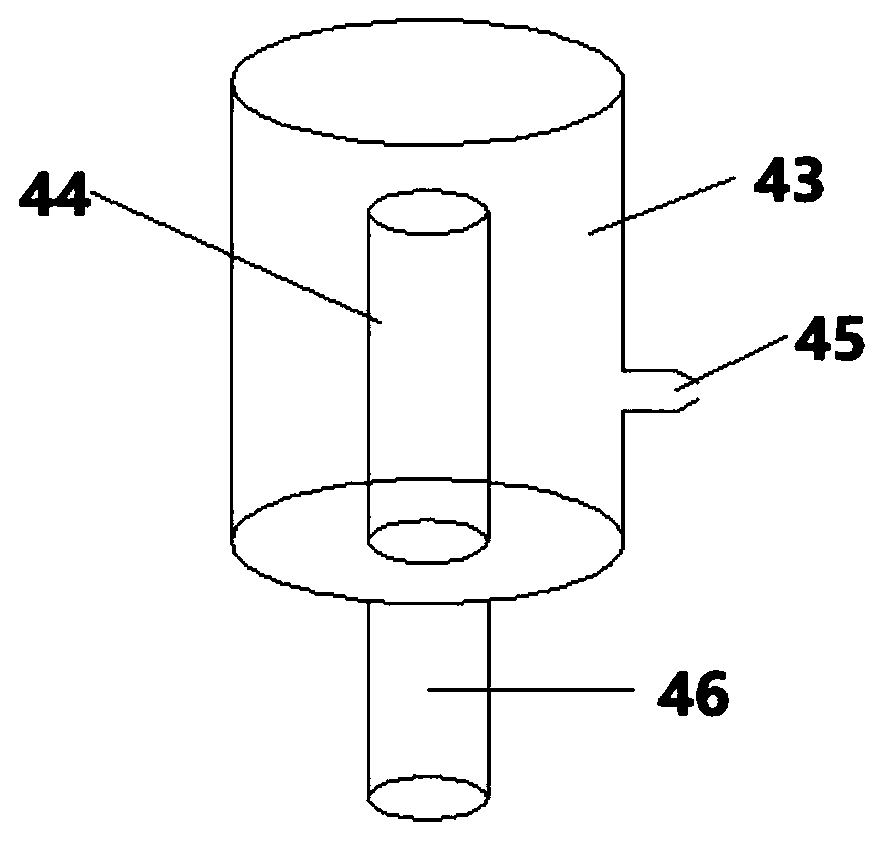

[0082] The implementation of this embodiment is the same as that of Example 1, except that the diameter ratio of the inner channel 39 of the dripper to the outer channel 41 of the dripper is 1:0.2; The internal diameter ratio is 1:1; Shearing cups 13, 14, 15 are made of the acrylic material sold by Yiwu Boyi Acrylic Products Firm under the trade name High Transparent Hard Acrylic. Confluence cup 29 is made of glass quality material; Forming standpipe 16,17,18 and forming coil pipe 30 are made of glass quality material; A modular PLC sold under the trade name DBL-8DI.

[0083] According to the GB 5606.4-2005 national standard, sensory evaluation was carried out on the popping beads prepared by the multi-dropper UV light-cured water-based capsule production equipment of this embodiment, and the specific evaluation results are listed in Table 2. At the sa...

Embodiment 3

[0086] Embodiment 3: the water-based capsule production equipment of multi-dropper UV photocuring of the present invention

[0087] The implementation of this embodiment is the same as that of Example 1, except that the diameter ratio of the inner channel 39 of the dripper to the outer channel 41 of the dripper is 1:2.0; The inner diameter ratio is 3:1; the shear cups 13, 14, 15 are made of glass material. Confluence cup 29 is to be made with transparent plastic material; Forming standpipe 16,17,18 and forming coil pipe 30 are to be made with transparent plastic material; Stacked PLC sold under the name FX2N.

[0088] According to the GB 5606.4-2005 national standard, sensory evaluation was carried out on the popping beads prepared by the multi-dropper UV light-cured water-based capsule production equipment of this embodiment, and the specific evaluation results are listed in Table 3. At the same time, under the same environmental conditions and formula, the pop-up beads pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com