Preparation method of W/O type mini emulsion

An emulsion and micro technology, applied in the field of skin care products, can solve problems such as heating, temperature control, homogenization, stirring, etc., and achieve the effects of short preparation time, energy saving, and water-encapsulating capacity improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of W / O type microemulsion provided by the invention, comprises the following steps successively:

[0035] 1) mixing and stirring the polyether-modified silicone emulsifier, monohydric alcohol, preservative and humectant evenly to obtain the first mixture;

[0036] 2) Add the fat, thickener and monohydric alcohol into the emulsification pot, stir evenly and homogenize to obtain the second mixture;

[0037] 3) Add preservatives, humectants and water into the water phase pot, stir and heat to 75-80°C, keep warm to dissolve, stir and cool down to below 40°C, stand by to obtain the third mixture;

[0038] 4) Add the co-emulsifier and the first mixture into the emulsification pot, mix with the second mixture evenly, then add the third mixture into the emulsification pot, stir evenly, and emulsify at a low speed to obtain a W / O microemulsion .

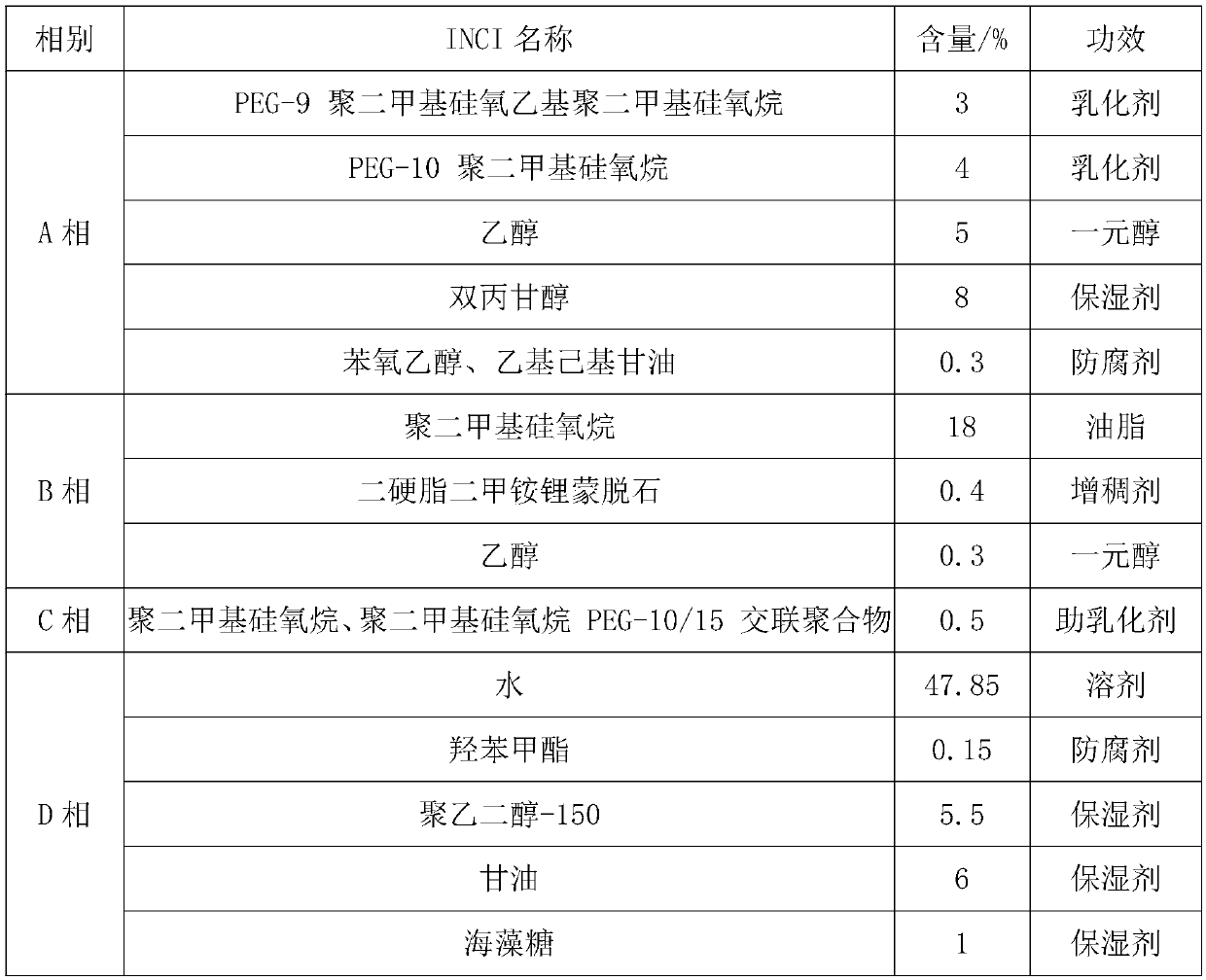

[0039] Each component in its emulsion is shown in Table 1.

[0040] Table 1

[0041]

Embodiment 2

[0043] A kind of preparation method of W / O type microemulsion provided by the invention, comprises the following steps successively:

[0044] 1) mixing and stirring the polyether-modified silicone emulsifier, monohydric alcohol and humectant evenly to obtain the first mixture;

[0045] 2) Add the fat, thickener and monohydric alcohol into the emulsification pot, stir evenly and homogenize to obtain the second mixture;

[0046] 3) Add preservatives, moisturizers, skin conditioning agents and water into the water phase pot, stir and heat to 80°C, keep warm to dissolve, stir and cool down to below 40°C, and stand by to obtain the third mixture;

[0047] 4) Add the co-emulsifier, emollient, fragrance and the first mixture into the emulsification pot, mix evenly with the second mixture, then add the third mixture into the emulsification pot, stir evenly, and emulsify at a low speed, that is A W / O type microemulsion was obtained.

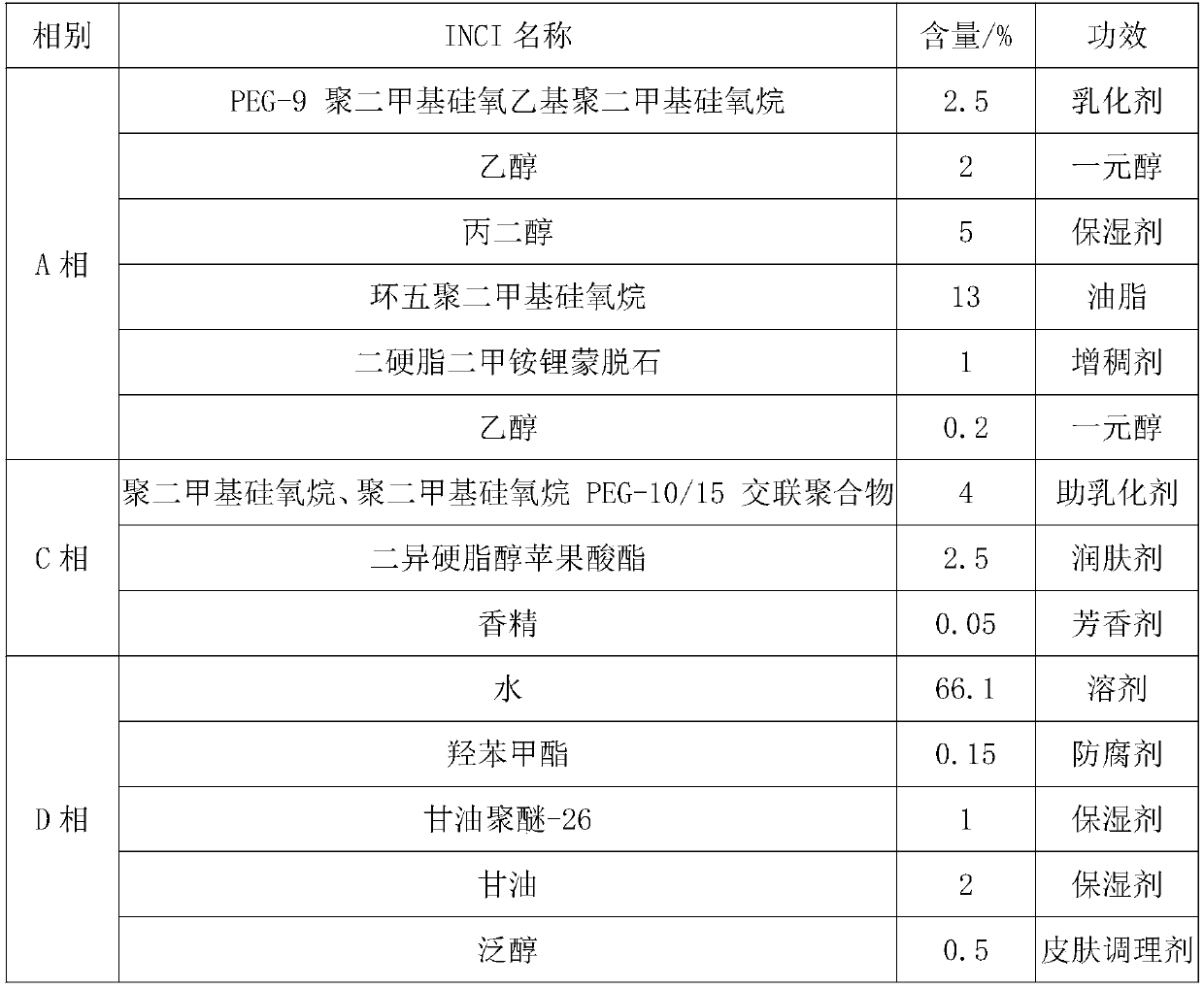

[0048] Each component in its emulsion is shown in...

Embodiment 3

[0052]A kind of preparation method of W / O type microemulsion provided by the invention, comprises the following steps successively:

[0053] 1) mixing and stirring the polyether-modified silicone emulsifier, glycol, preservative and humectant evenly to obtain the first mixture;

[0054] 2) Add the fat, thickener and monohydric alcohol into the emulsification pot, stir evenly and homogenize to obtain the second mixture;

[0055] 3) Add the humectant and water into the water phase pot, stir and heat to 78°C, keep warm to dissolve, stir and cool down to below 40°C, and set aside to obtain the third mixture;

[0056] 4) Add the co-emulsifier, emollient, fragrance and the first mixture into the emulsification pot, mix evenly with the second mixture, then add the third mixture into the emulsification pot, stir evenly, and emulsify at a low speed, that is A W / O type microemulsion was obtained.

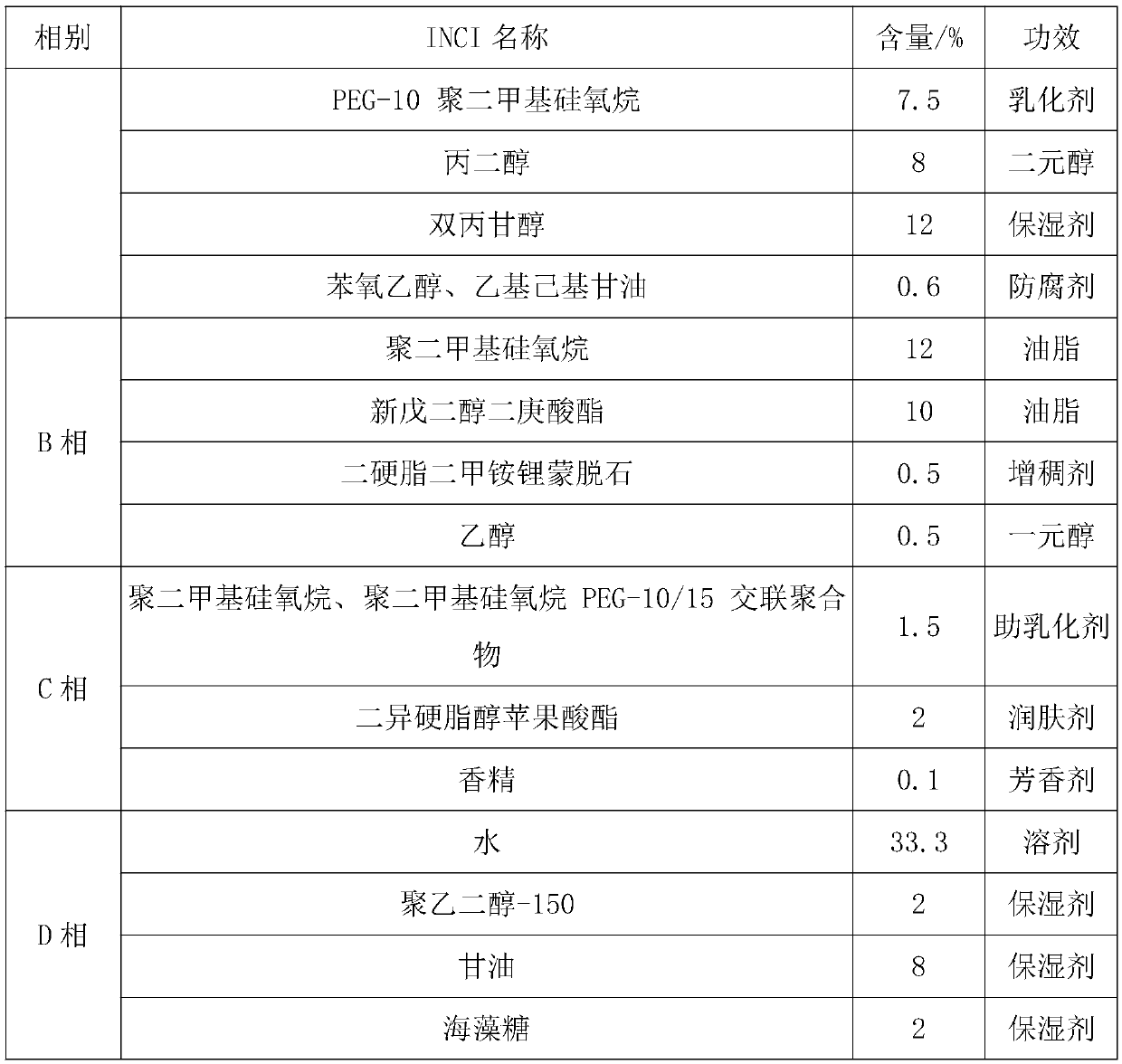

[0057] Each component in its emulsion is shown in Table 3.

[0058] table 3

[0059] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com