A kind of preparation method of layered composite plate of 6061 aluminum alloy and t2 copper

An aluminum alloy plate and aluminum alloy technology, applied in metal rolling and other directions, can solve the problems of high production cost, high energy consumption, long production cycle, etc., and achieve good interfacial shear bonding strength, high thermal conductivity, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific Embodiment 1: In this embodiment, a method for preparing a layered composite board of 6061 aluminum alloy and T2 copper is completed according to the following steps:

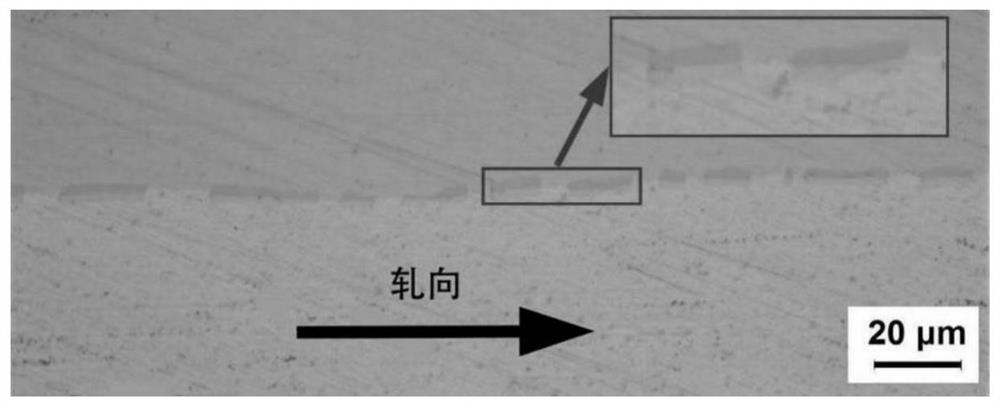

[0015] 1. Saw the 6061 aluminum alloy ingot to obtain a 6061 aluminum alloy plate with a length of 4000mm-5000mm, a width of 1200mm-1400mm, and a thickness of 400mm-450mm, and then mill the 6061 aluminum alloy plate to a thickness of 385mm-395mm. Keep the milled 6061 aluminum alloy plate at a temperature of 440°C-460°C for 20min-40min, and hot-roll the thickness of the 6061 aluminum alloy plate to 2mm-10mm under the same temperature condition; saw the T2 copper ingot Cut into a length of 4000mm-5000mm, a width of 1200mm-1400mm, and a thickness of 400mm-450mm to obtain a T2 copper plate, keep the T2 copper plate at a temperature of 480°C-500°C for 20min-40min, and heat the T2 copper plate under the same temperature condition. The thickness of the copper plate is hot-rolled to 2mm-10mm, and finall...

specific Embodiment approach 2

[0021] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the main elements and mass fractions contained in the 6061 aluminum alloy ingot described in step 1: Si is 0.2% to 1.0%, and Fe is 0.5% to 1.0% %, Cu is 0.15%~0.50%, Mn is 0.10%~0.50%, Mg is 0.04%~0.50%, Cr<0.40%, Zn is 0.10%~0.15%, Ti is 0.02%~0.04%, and total impurities< 0.15%, the balance is Al.

[0022] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the 6061 aluminum alloy ingot described in step 1 is prepared according to the following steps:

[0024] (1) Weigh pure aluminum ingots, pure magnesium ingots, pure zinc ingots, aluminum-silicon master alloys, aluminum-manganese master alloys, aluminum-copper master alloys and aluminum-titanium master alloys according to the main elements and mass fractions contained in 6061 aluminum alloy ingots;

[0025] (2) After melting part of the pure aluminum ingots weighed in step (1), pour them into the base in the crystallizer, and then pour the pure zinc ingots, aluminum-silicon intermediate alloys, and aluminum-manganese intermediates weighed in step (1) Alloy, aluminum-copper master alloy, aluminum-titanium master alloy and the remaining pure aluminum ingots are added to the melting furnace, the temperature is raised to 740 ° C ~ 760 ° C, after melting, stirring is carried out and the slag is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com