Manufacturing process of optical fiber preform

An optical fiber preform and manufacturing process technology, which is applied to manufacturing tools, glass manufacturing equipment, glass deposition furnaces, etc., can solve the problems of internal airflow disturbance, large size of the torch, affecting the deposition quality of silica particles, etc., and achieve spatial disturbance. The effect of reducing, good deposition quality and ensuring deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

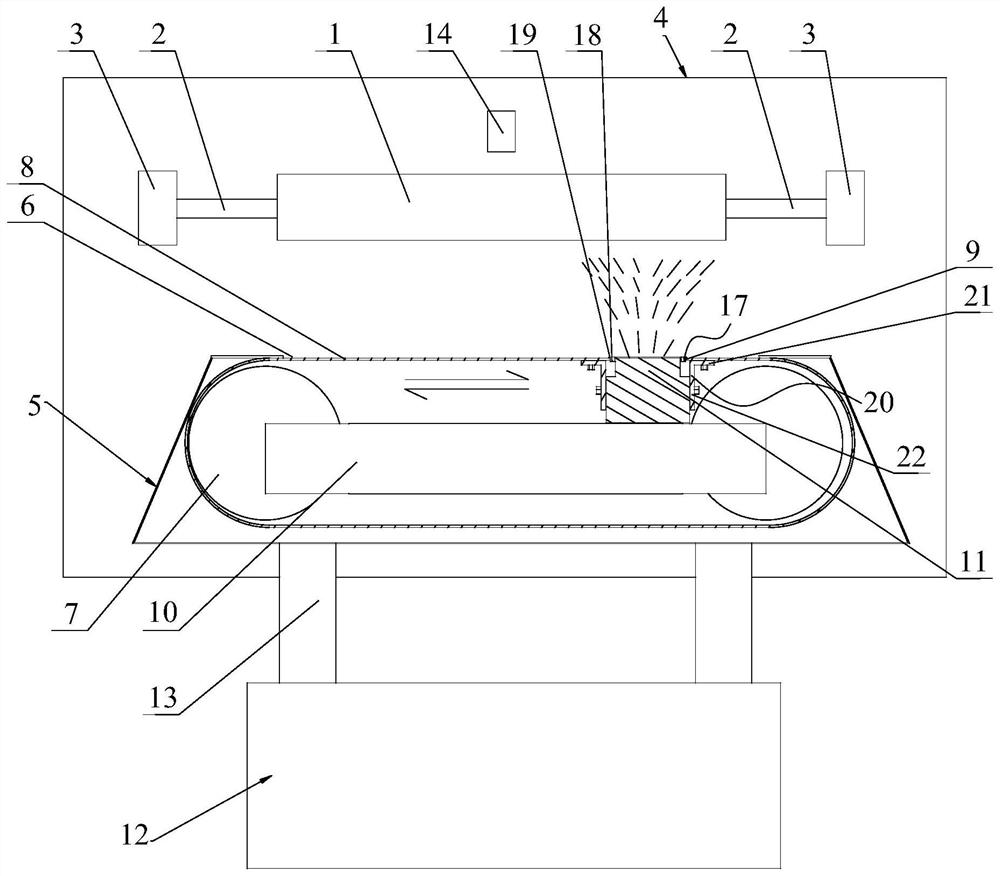

[0045] Below in conjunction with each accompanying drawing, the present invention is described in detail.

[0046] A manufacturing process for an optical fiber preform, comprising the following steps:

[0047] 1) An auxiliary rod is welded at both ends of the mandrel, and the two auxiliary rods are respectively clamped on two chucks, and the chuck drives the auxiliary rod and the mandrel to rotate;

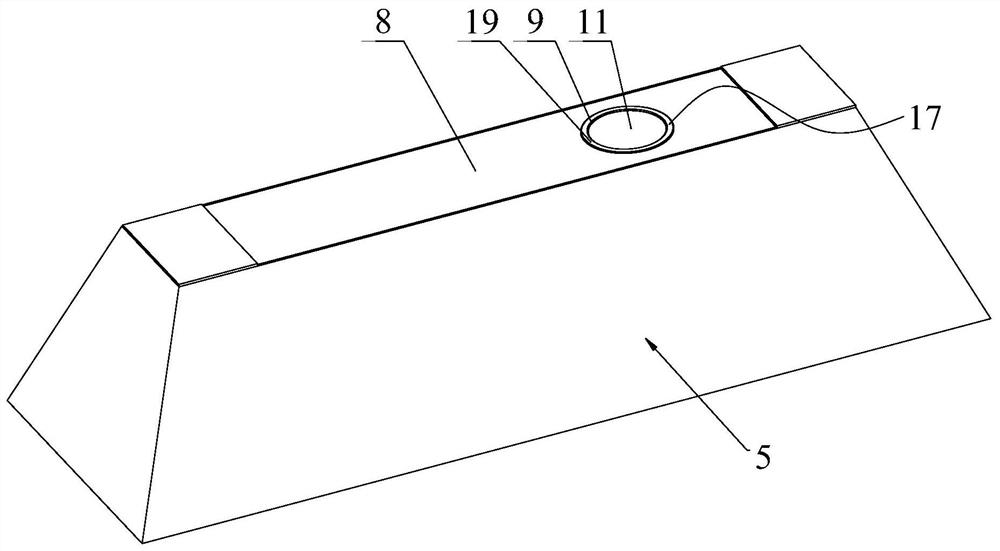

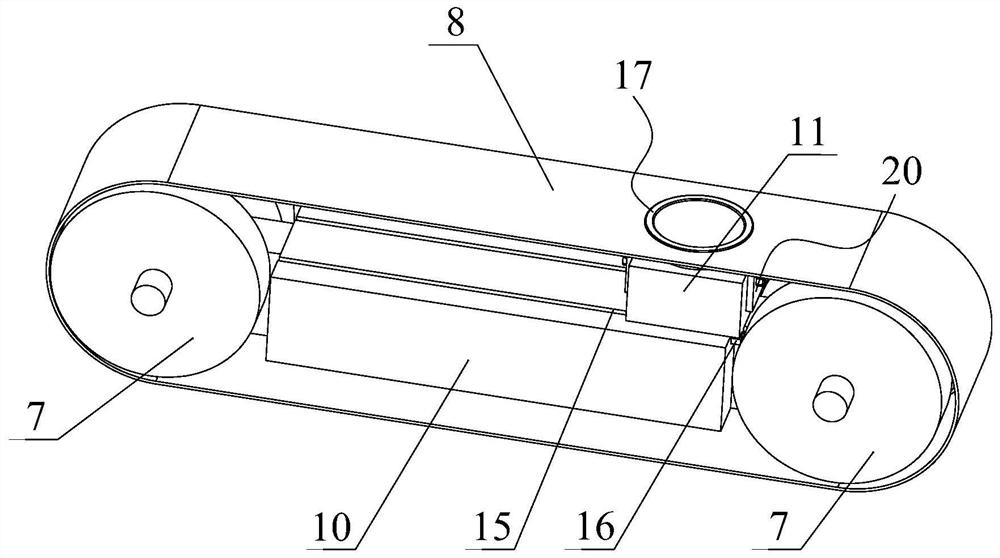

[0048] 2) Set the conveyor belt under the mandrel, the conveyor belt is provided with a through hole, set the blowtorch inside the conveyor belt and connect with the conveyor belt, and the nozzle of the blowtorch is located inside the through hole or flush with the upper surface of the conveyor belt through the through hole, and the conveyor belt reciprocates The movement drives the blowtorch to reciprocate along the length direction of the mandrel, and the blowtorch makes the outer surface of the mandrel precipitate loose particles;

[0049] 3) Measure the outer diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com