Formula of neutral anti-slip agent for ceramic tiles and preparation method of neutral anti-slip agent

A technology of anti-slip agent and ceramic tile, which is applied in the field of anti-slip agent, and can solve the problems of increasing the cost of anti-slip agent, increasing the volatilization speed of anti-slip agent, and fast air flow speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

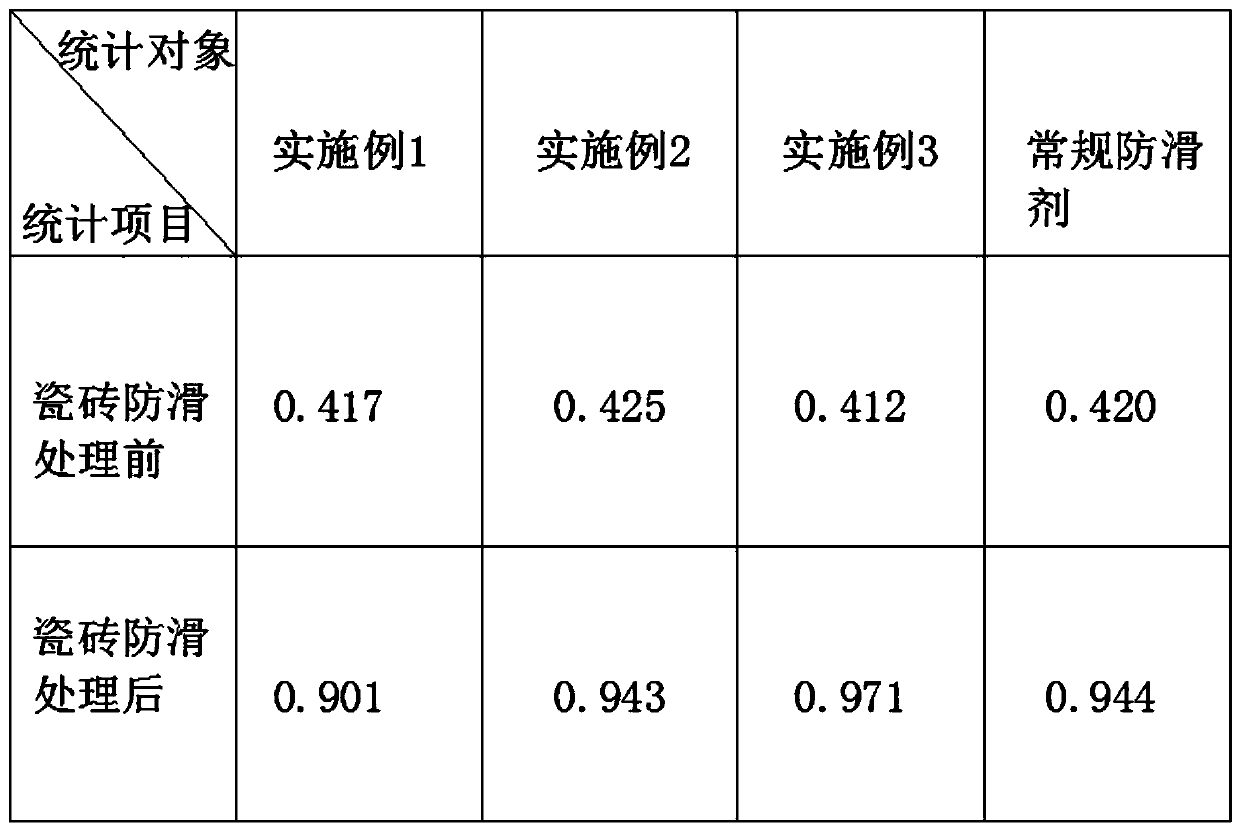

Examples

Embodiment 1

[0028] S1. Preparation of purified water: Weigh 600 parts of tap water into the crucible through a measuring cup, heat to boiling, and continue heating for 15-20 minutes to carry out disinfection treatment to remove bacteria in the water. After filtering through the filter, pass through the measuring cup Put it in full bloom to obtain sterilized purified water;

[0029] S2. Extraction of plant extract: more than one kind of bark, branches and leaves selected from the components composed of Chrysanthemum chrysanthemum and phoenix phoenix are washed with water, and the washed bark, branches and leaves are crushed and ground with a pestle, and yeast powder is added Seal it for fermentation, ferment at 20-25°C for 3-5 days, and filter to obtain the plant extract;

[0030] S3. Mix the anti-slip agent evenly: add 600 parts of purified water in the prescription amount to the reactor, heat it to 70°C, add 150 parts of inorganic salt in the prescription amount and 3 parts of plant extr...

Embodiment 2

[0033] S1. Preparation of purified water: Weigh 650 parts of tap water into the crucible through a measuring cup, heat to boiling, continue heating for 15-20 minutes to carry out disinfection treatment to remove bacteria in the water well, filter through the filter and pass through the measuring cup Put it in full bloom to obtain sterilized purified water;

[0034]S2. Extraction of plant extract: more than one kind of bark, branches and leaves selected from the components composed of Chrysanthemum chrysanthemum and phoenix phoenix are washed with water, and the washed bark, branches and leaves are crushed and ground with a pestle, and yeast powder is added Seal it for fermentation, ferment at 20-25°C for 3-5 days, and filter to obtain the plant extract;

[0035] S3. The anti-slip agent is mixed evenly: add 650 parts of purified water in the prescribed amount to the reactor, heat it to 70°C, add 175 parts of inorganic salts in the prescribed amount and 4 parts of plant extract ...

Embodiment 3

[0038] S1. Preparation of purified water: Weigh 600 parts of tap water into the crucible through a measuring cup, heat to boiling, and continue heating for 15-20 minutes to carry out disinfection treatment to remove bacteria in the water. After filtering through the filter, pass through the measuring cup Put it in full bloom to obtain sterilized purified water;

[0039] S2. Extraction of plant extract: more than one kind of bark, branches and leaves selected from the components composed of Chrysanthemum chrysanthemum and phoenix phoenix are washed with water, and the washed bark, branches and leaves are crushed and ground with a pestle, and yeast powder is added Seal it for fermentation, ferment at 20-25°C for 3-5 days, and filter to obtain the plant extract;

[0040] S3. Mix the anti-slip agent evenly: add 600 parts of purified water in the prescription amount to the reactor, heat it to 70°C, add 200 parts of inorganic salt in the prescription amount and 5 parts of plant extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com