Method for preparing natural benzaldehyde byspraying and continuous hydrolysis

A benzaldehyde and natural technology, which is applied in the field of spraying continuous hydrolysis to prepare natural benzaldehyde, can solve the problems of reducing the natural degree of benzaldehyde, uneven dispersion of cinnamaldehyde, and long retention time of cinnamaldehyde, so as to improve the utilization rate of raw materials and the natural degree High, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

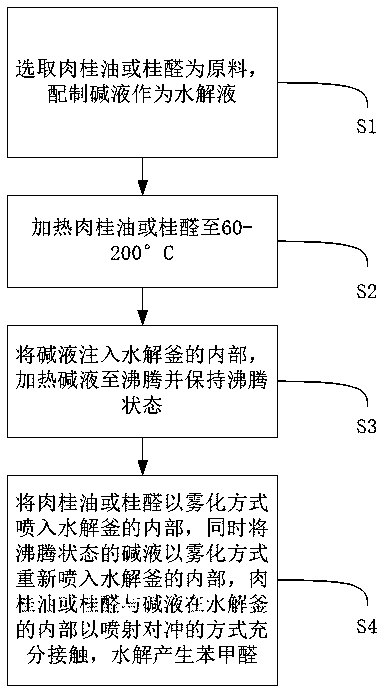

Method used

Image

Examples

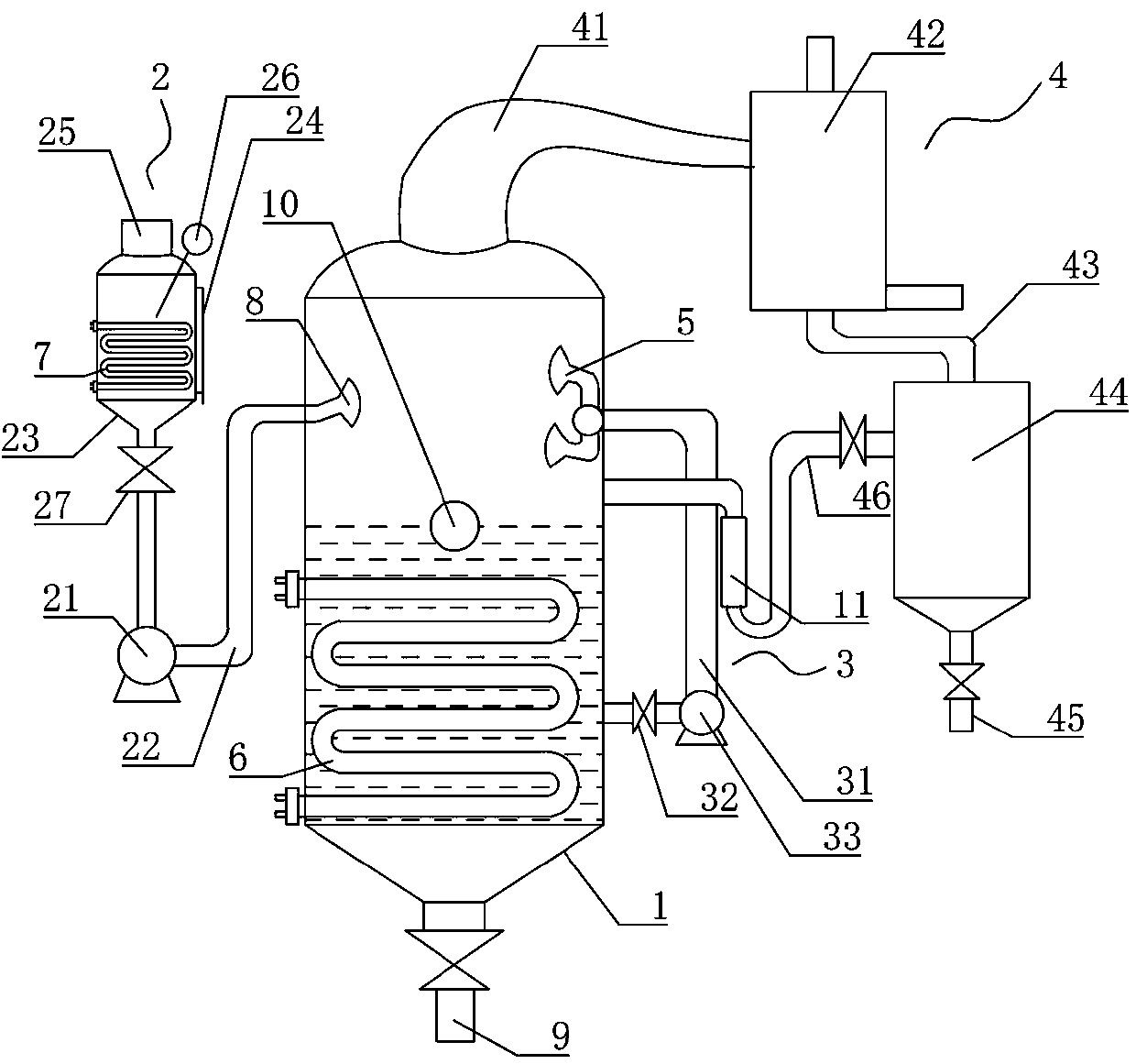

Embodiment 1

[0050] 1. Add clean water to the oil-water separator until the water comes out of the return pipe.

[0051] 2. Prepare lye with NaOH solution with a mass concentration of 2% and Na2CO3 solution with a mass concentration of 2%, then add the prepared lye to the middle of the sight glass of the hydrolysis kettle, turn on the steam, and the steam enters the lye heating coil , through the lye heating coil to heat the lye to a boiling state, the generated steam is collected and condensed to the return pipe of the oil-water separator and returned to the hydrolysis kettle, and the flow rate of the returned water reaches 250kg / h.

[0052] 3. Spray continuous hydrolysis: Start the lye circulation pump, control the flow rate to 300kg / h, and the pressure to 0.09MPa, and spray lye into the hydrolysis kettle from 10 lye nozzles installed in the hydrolysis kettle. Start the raw material metering pump, and spray 110°C hydrolyzed raw material cinnamaldehyde (cinnamaldehyde content 95.2%) into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com