Haematococcus pluvialis JNU 35 with high astaxanthin yield, culture method and application thereof

A technology of Haematococcus pluvialis and its cultivation method, applied in the field of Haematococcus pluvialls JNU35 and its cultivation, can solve the problems of complex induction conditions, difficulty in achieving biomass of Haematococcus pluvialis, low astaxanthin production, etc. Achieve the effects of increasing biomass and astaxanthin content, good industrial production prospects, and high operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

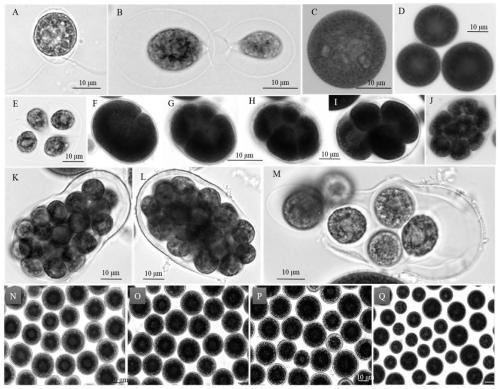

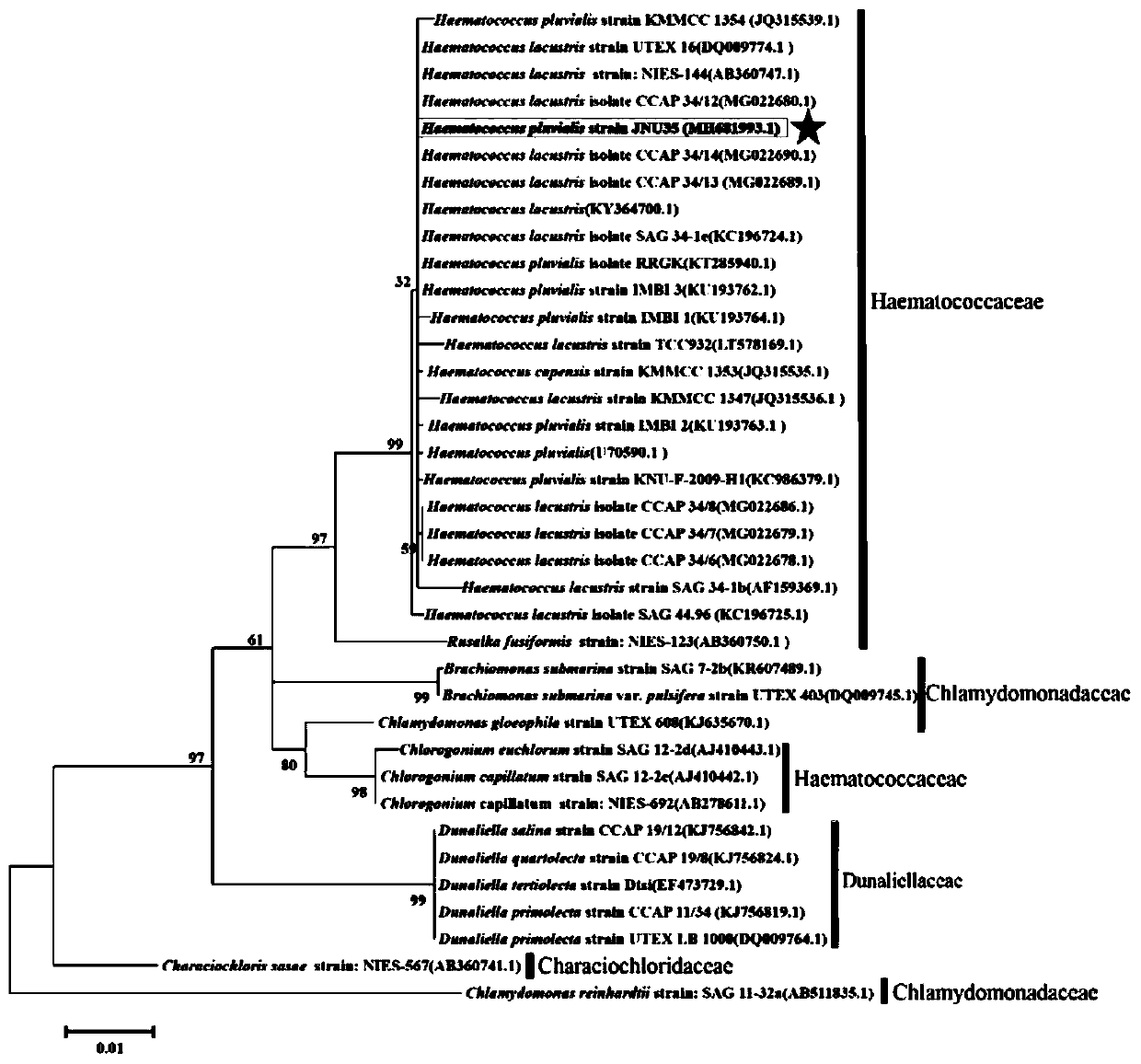

[0052] Isolation and Identification of Embodiment 1 JNU35

[0053] 1. Algae sample collection, separation and purification

[0054] The improved BG-11 medium in this example is to add NaNO with a nitrogen concentration of 18mmol / L to the above-mentioned nitrogen-free improved BG-11 medium 3 be made of.

[0055] Take the water sample from the small sand pond beside the Jiageng stream in Gongga Mountain, Sichuan, at an altitude of 3948 meters, back to the laboratory, take 1mL water sample, add it to a 100mL triangular flask containing 50mL of improved BG-11 medium, and set up 5 In parallel, culture under continuous light at 25°C for 5 days, then transfer 1 mL of the culture sample to a 1.5 mL sterile EP tube under aseptic operation every day, observe whether there are algae cells growing, and take 5 μL of algae containing the target algae smeared on the solid plate of improved BG-11 medium (solid medium was added to agar 20g / L), and cultured under continuous light at 25°C. Af...

Embodiment 2

[0072] The influence of embodiment 2 different initial nitrogen concentrations on JNU35

[0073] 1. Preparation of Algae Seeds

[0074] Firstly, the aseptic JNU35 algae species preserved in the conical flask were amplified step by step into a glass columnar photobioreactor with a light path of 10 cm. After the algae cultured to the logarithmic growth phase are settled and washed with sterile water, the algae cells are collected as the secondary algae species, and then the subsequent culture is carried out.

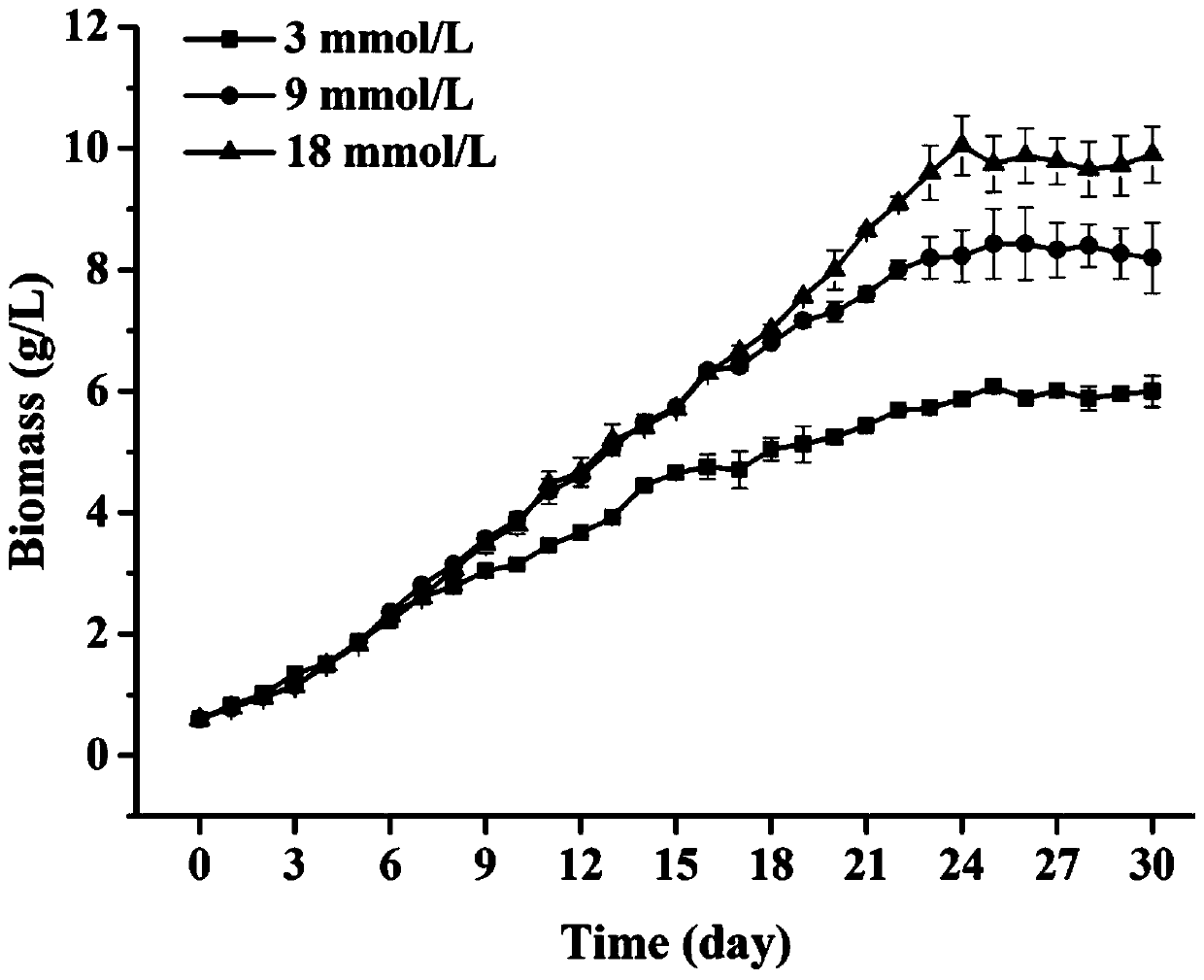

[0075] 2. Changes in biomass under different initial nitrogen concentrations

[0076] With the initial inoculum concentration of OD750=0.50~0.90, in The glass columnar photobioreactor was cultivated, and a two-step culture strategy was adopted. In the first stage, the improved BBM medium was selected, and CO(NH 2 ) 2 As the nitrogen source, set different initial nitrogen concentrations (3mmol / L, 9mmol / L and 18mmol / L), and the 24h single-side light intensity is 100-200...

Embodiment 3

[0082] The influence of embodiment 3 different light intensities on JNU35

[0083] exist The glass columnar photobioreactor was cultivated, inoculated with the initial concentration of OD750=0.50~0.90, the medium of the first stage was the improved BBM medium, and the nitrogen source was CO(NH 2 ) 2 (Nitrogen concentration is 18mmol / L), 24h single side light intensity 100~200μmol·m -2 ·s -1 Continuous light, culture temperature 25~30℃, feed with 1% CO 2 compressed air for agitation. After 15 days of culture, transfer to the second stage, transfer the algae cells to the nitrogen-free BBM medium, and set the light intensity on one side for 24 hours to 300 μmol·m -2 ·s -1 and double-sided light intensity 300μmol·m -2 ·s -1 Continuous light, other conditions are consistent with the first stage. Comparison of the effects of light intensity on JNU35 growth and astaxanthin accumulation.

[0084] Such as Figure 5 It shows that the biomass of JNU35 reaches 5.1g / L after 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com