Hypersonic aircraft thermal protection material ground simulation test system and method

A thermal protection material and ground simulation technology, applied in the field of laser technology and application, can solve the problems of lack of hot air flow conditions, low test cost, and inability to truly simulate the oxidation and ablation effect of re-entry environment, so as to avoid long preparation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

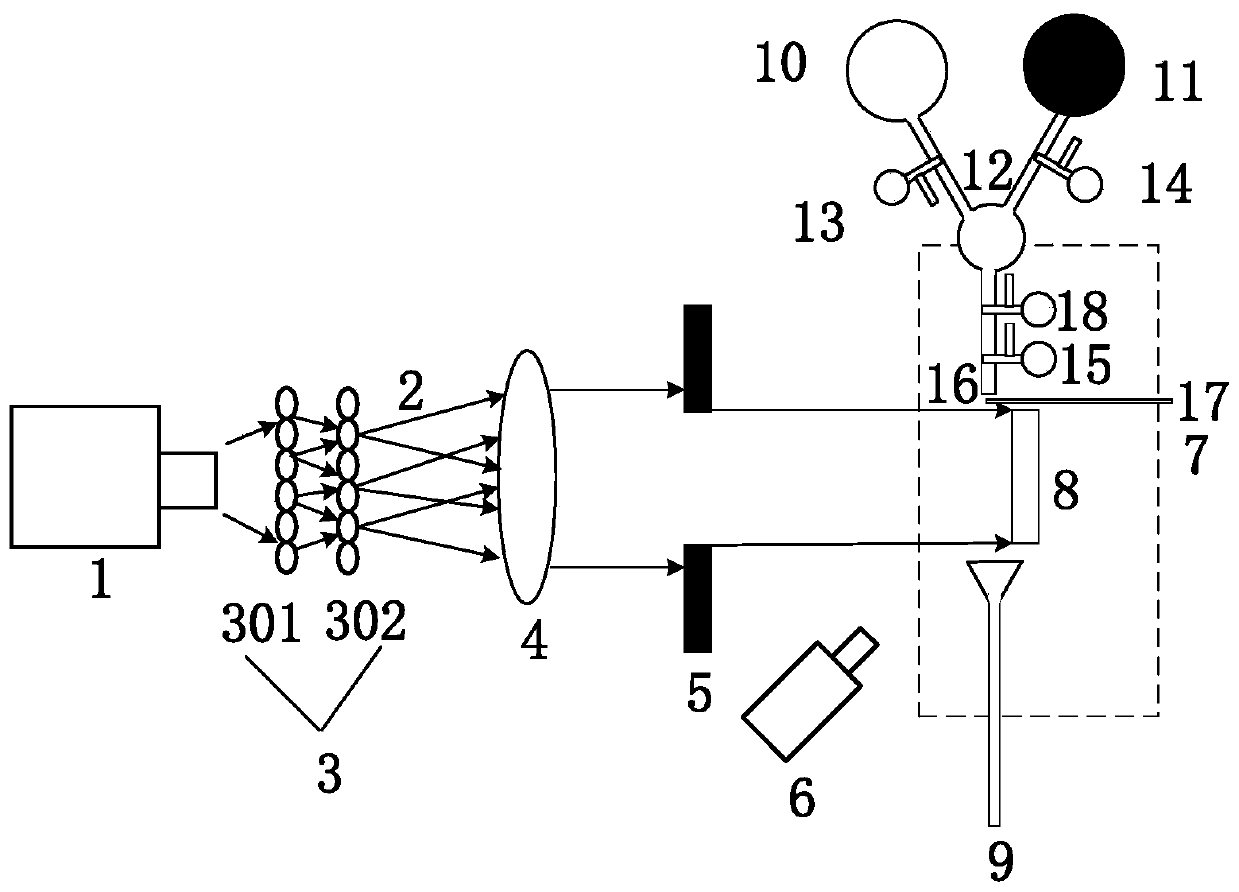

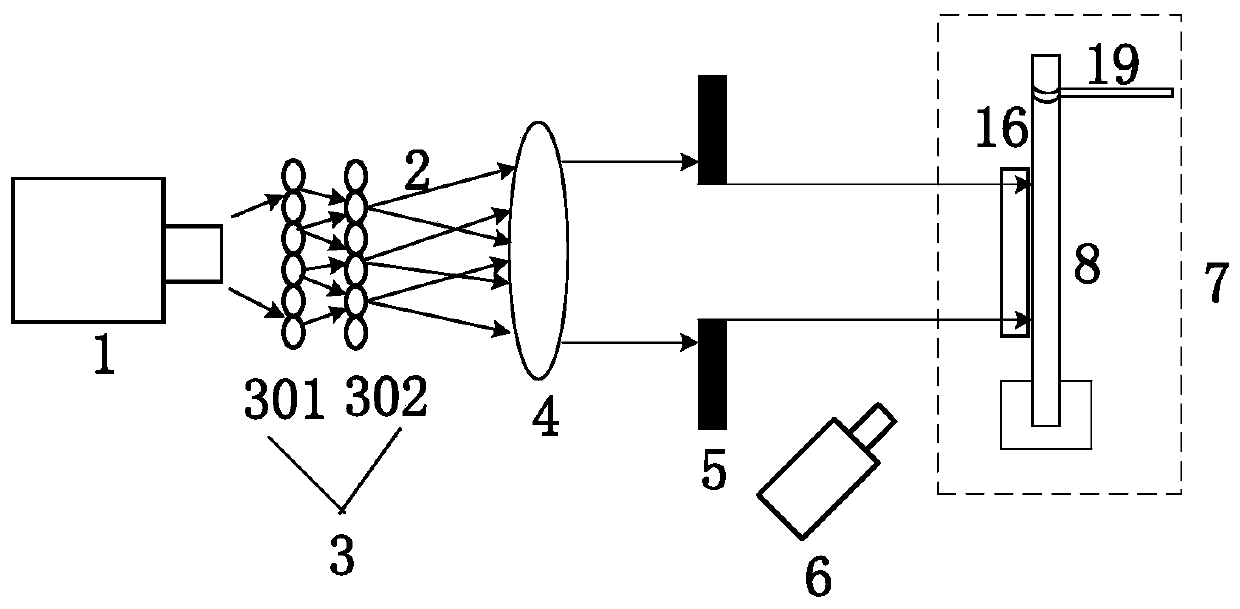

[0078] see figure 1 and figure 2 , a ground simulation test system for thermal protection materials for hypersonic aircraft, including a laser 1, a laser beam 2, a microlens array 3, a collimating lens 4, a graphite diaphragm 5, a thermal imager 6, an electronic universal testing machine 7, and a test piece 8. Down suction device 9, oxygen cylinder 10, nitrogen cylinder 11, mixing container 12, oxygen flow control valve 13, nitrogen flow control valve 14, mixed gas flow control valve 15, air flow nozzle 16, pitot tube 17 , barometer 18 and mechanical loading rod 19;

[0079] The test piece 8 is installed on the electronic universal testing machine 7;

[0080] The laser beam 2 generated by the laser 1 passes through the microlens array 3, the collimator lens 4 and the graphite diaphragm 5 in sequence, and then the laser beam emitted from the small hole of the graphite diaphragm 5 covers the test piece 8 completely;

[0081] The thermal imager 6 is used to monitor the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com