A kind of soybean protein adhesive, plywood and preparation method thereof

A soybean protein and adhesive technology, which is applied in the preparation of protein adhesives, animal glue or gelatin, adhesives, etc., can solve the problems that limit the improvement of the quality of solid wood particle boards, formaldehyde release exceeds the standard, and endanger human health. The effect of formaldehyde emission exceeding the standard, improving mechanical strength and water resistance, and reducing exercise resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

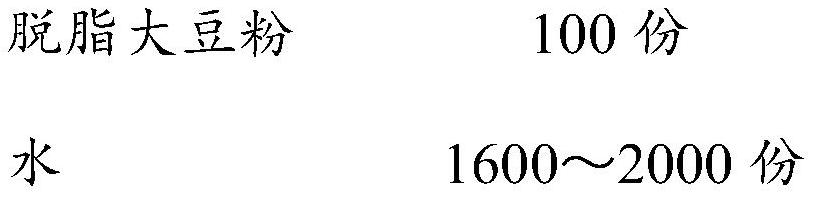

[0021] 1, the soybean protein adhesive of the present embodiment adopts the raw material of following parts by weight to make:

[0022]

[0023]

[0024] 2. Preparation of plywood

[0025] Step 1. Prepare the soybean protein adhesive: according to the above ratio, mix the defatted soybean powder with water uniformly, dissolve the aluminum hydroxide alkali, and add malic acid, glutamic acid, dodecylbenzenesulfonic acid, and dispersant in turn , stirring and mixing to modify it to obtain soybean protein adhesive.

[0026] Step 2. Cut the wood raw material into wood chips of the required specifications;

[0027] Step 3, after sorting the obtained wood chips and shaving out qualified shavings, drying until the shavings reach a moisture content of 5%, and shaving the core layer to obtain core layer particles;

[0028] Step 4, spraying glue on the obtained core layer particles, adding 5% of the soy protein adhesive by weight of the wood raw material when spraying glue, then ...

Embodiment 2

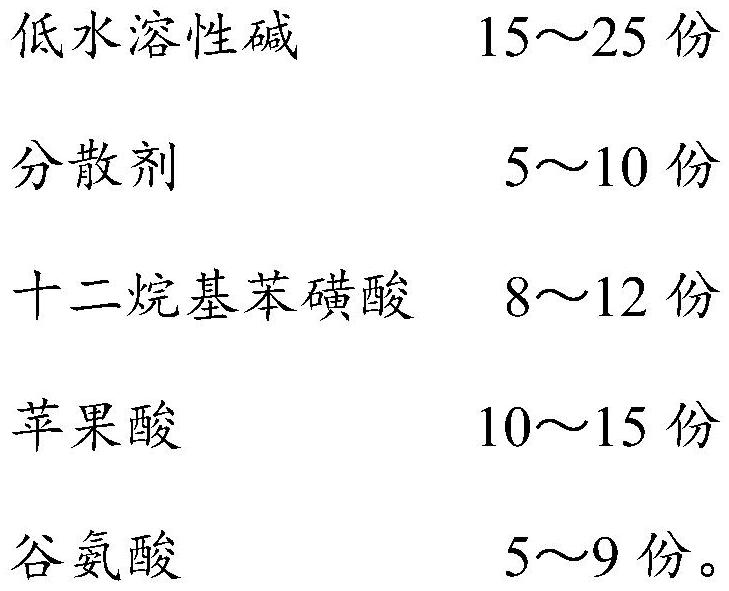

[0032] 1, the soybean protein adhesive of the present embodiment adopts the raw material of following parts by weight to make:

[0033]

[0034]

[0035] 2. Preparation of plywood

[0036] Step 1. Prepare the soybean protein adhesive: according to the above ratio, mix the defatted soybean powder with water uniformly, dissolve the aluminum hydroxide alkali, and add malic acid, glutamic acid, dodecylbenzenesulfonic acid, and dispersant in turn , stirring and mixing to modify it to obtain soybean protein adhesive.

[0037] Step 2. Cut the wood raw material into wood chips of the required specifications;

[0038] Step 3, after sorting the obtained wood chips and shaving out qualified shavings, drying until the shavings reach a moisture content of 2%, and shaving the core layer to obtain core layer particles;

[0039] Step 4, spray glue on the obtained core layer particles, add 1% of the soy protein adhesive by weight of the wood raw material when spraying the glue, then ad...

Embodiment 3

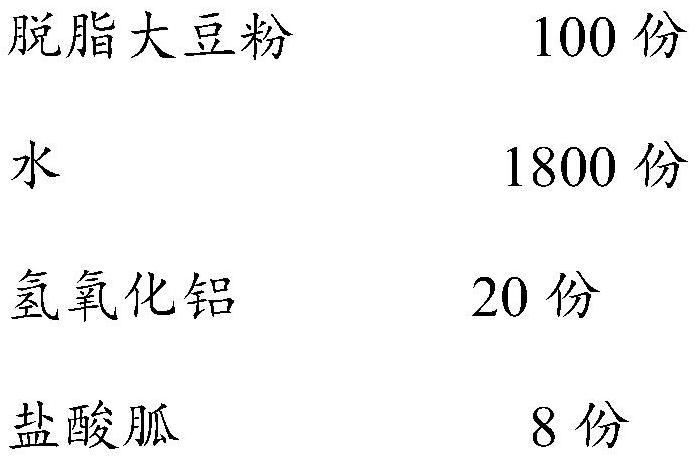

[0043] 1, the soybean protein adhesive of the present embodiment adopts the raw material of following parts by weight to make:

[0044]

[0045]

[0046] 2. Preparation of plywood

[0047] Step 1. Prepare the soybean protein adhesive: according to the above ratio, mix the defatted soybean powder with water uniformly, dissolve the aluminum hydroxide alkali, and add malic acid, glutamic acid, dodecylbenzenesulfonic acid, and dispersant in turn , stirring and mixing to modify it to obtain soybean protein adhesive.

[0048] Step 2. Cut the wood raw material into wood chips of the required specifications;

[0049] Step 3, after sorting the obtained wood chips and shaving out qualified shavings, drying until the shavings reach a moisture content of 8%, and shaving the core layer to obtain core layer particles;

[0050] Step 4, spray glue on the obtained core layer particles, add 10% of the soy protein adhesive by weight of the wood raw material when spraying the glue, then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com