Composite surfactant oil displacement system suitable for high calcium and magnesium oil reservoir, and preparation method of composite surfactant oil displacement system

A composite surfactant, high calcium and magnesium technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of weak resistance to calcium and magnesium ions, etc., achieve excellent oil displacement performance, broad application prospects, Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

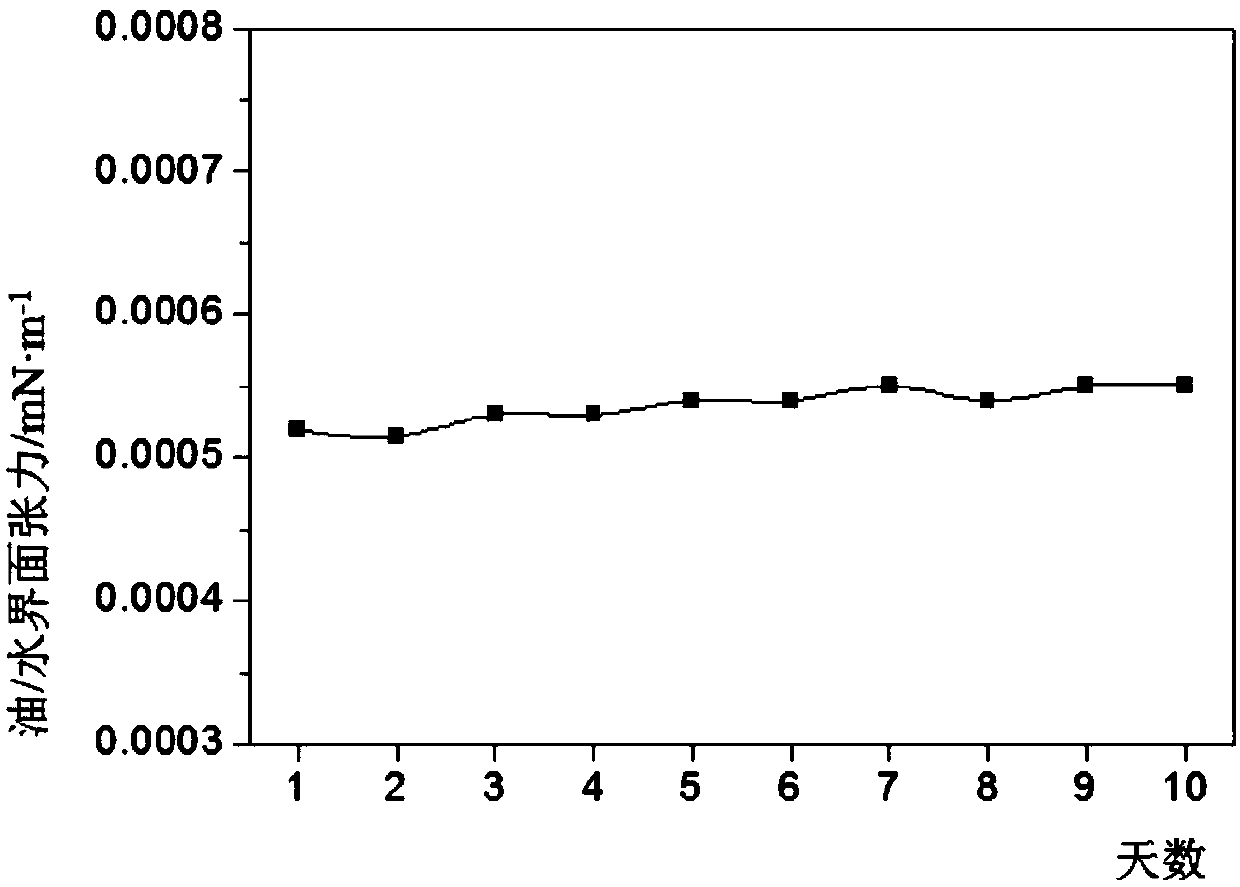

Image

Examples

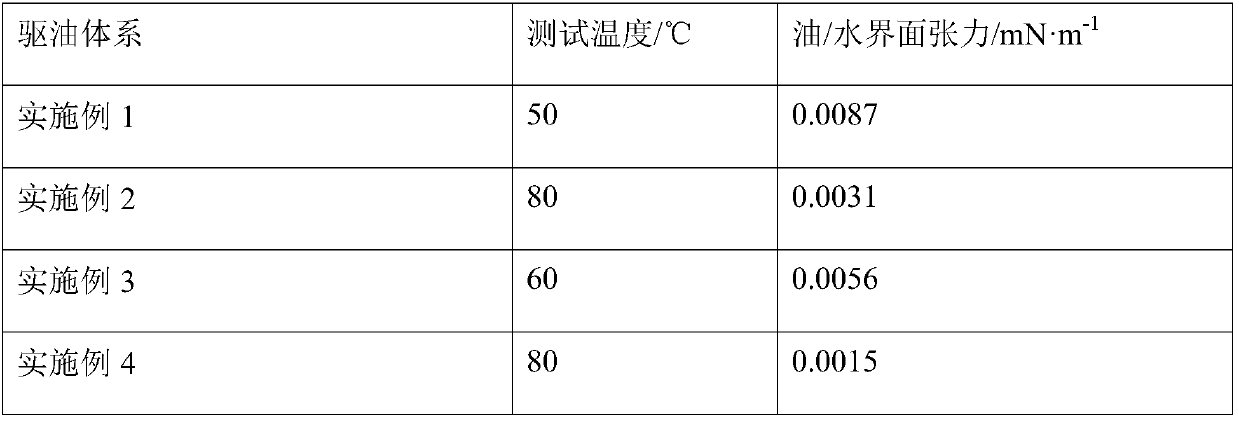

Embodiment 1

[0025] Take 0.03g of capric acid diethanolamide and 0.12g of fatty alcohol polyoxyethylene ether sodium sulfate and add them to 99.85g of simulated formation water. The calcium and magnesium ion content of the simulated formation water is 2000mg / L, and the total salinity is 60000mg / L. Stir for 0.5 hour to fully dissolve the surfactant, and then use hydrochloric acid to adjust the pH of the system to neutral to obtain a transparent oil displacement system without precipitation.

Embodiment 2

[0027] Take 0.16g of lauric acid diethanolamide and 0.04g of fatty alcohol polyoxyethylene ether sodium sulfate and add them to 99.80g of simulated formation water. The calcium and magnesium ion content of the simulated formation water is 2000mg / L, and the total salinity is 20000mg / L. Stir for 1.5 hours to fully dissolve the surfactant, and then use hydrochloric acid to adjust the pH of the system to neutral to obtain a transparent oil displacement system without precipitation.

Embodiment 3

[0029] Take 0.75g of myristic acid diethanolamide and 0.05g of fatty alcohol polyoxyethylene ether sodium sulfate and add them to 99.20g of simulated formation water. The calcium and magnesium ion content of the simulated formation water is 600mg / L, and the total salinity is 5000mg / L. Stir for 1.0 hour to fully dissolve the surfactant, and then use hydrochloric acid to adjust the pH of the system to neutral to obtain a transparent oil displacement system without precipitation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com