Wet metallurgy process of high-silicon zinc concentrate

A technology of hydrometallurgy and zinc concentrate, which is applied in the direction of photography process, photography auxiliary process, and process efficiency improvement, etc., can solve the problem of silica gel affecting liquid-solid separation, and achieves the solution of liquid-solid separation problem, the process is simple, and the process is feasible. Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. The main components of high silicon zinc concentrate are shown in the table below

[0042] element Zn SiO 2

S Fe Pb Cd Cu content / % 56.82 8.08 28.06 1.40 0.68 0.24 0.057

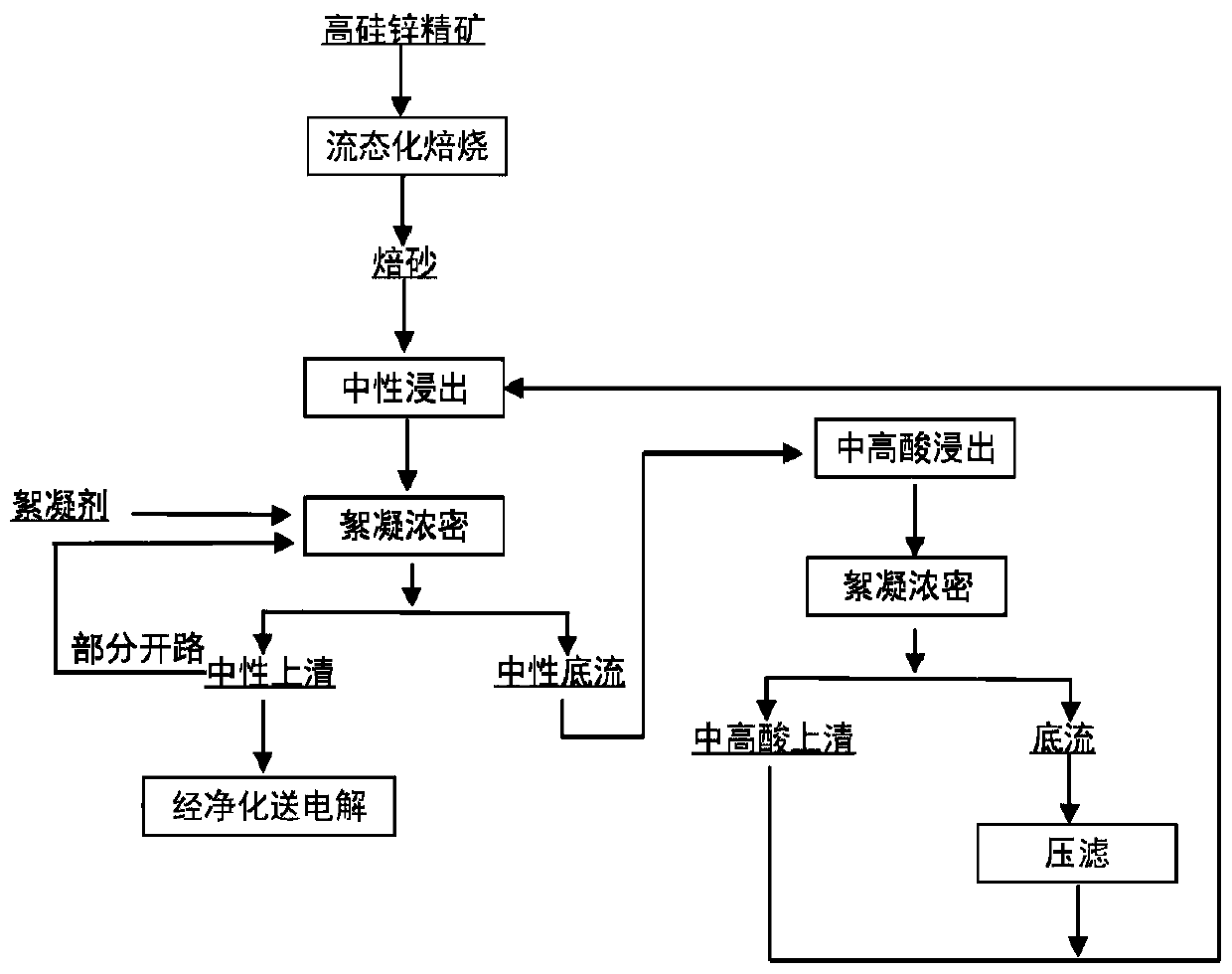

[0043] Two, the main process

[0044] Fluidized roasting of high-silicon zinc concentrate, neutral leaching of calcined sand with oxidizing solution of conventional wet zinc smelting process, thick neutral leaching pulp, overflow sent to purify and recover zinc; middle leaching underflow is carried out with waste electrolyte Medium and high acid leaching, after leaching, the ore pulp is flocculated densely with flocculant.

[0045] 3. Main process conditions and results

[0046] 1. Zinc concentrate particle size: -250 mesh sieve ≥ 82wt%.

[0047] 2. Fluidized roasting of high-silicon-zinc concentrate, the roasting temperature is 900°C, the excess air coefficient is 1.3, and the furnace bottom pressure is 12kPa. The yield of calcined sand is 84.60%, the...

Embodiment 2

[0051] Take high-silicon-zinc concentrate containing 51% zinc, 27.5% sulfur, and 12.3% silicon dioxide; carry out fluidized roasting on the high-silicon-zinc concentrate, the roasting temperature is 880°C, and the roasting desulfurization rate is 98.5%; The oxidizing solution in the zinc smelting process of the method is used for neutral leaching of calcined sand. The oxidizing solution for intermediate leaching is composed of spent electrolyte, mixed solution, anode mud slurry and manganese ore slurry. The intermediate leaching temperature is 80°C, and the leaching liquid-solid ratio is 10:1. The leaching time is 3 hours, the pH value of the leaching end point is 5.2, the neutral leaching pulp is dense, and the overflow is sent to purify to recover zinc; the middle and high acid leaching is carried out with the waste electrolyte in the middle leaching bottom flow, and the temperature is controlled at 70°C. The ratio of leaching liquid to solid is 5:1. After 3 hours, the pH val...

Embodiment 3

[0053] 1. The main components of high silicon zinc concentrate are shown in the table below

[0054] element Zn S Fe SiO 2

Pb mn CaO MgO content 57.00 30.08 1.58 7.37 0.41 0.026 0.42 0.12 element Al Ni co Cu Cd Ga Ge In content 0.58 0.0012 0.0011 0.049 0.25 <0.0005 <0.0005 <0.0005 element Hg As Sb Cr F Cl Ag(g / t) content 0.001 0.008 0.0020 0.046 0.008 0.01 18.73

[0055] Two, the main process

[0056] Fluidized roasting of high-silicon zinc concentrate, neutral leaching of calcined sand with oxidizing solution of conventional wet zinc smelting process, thick neutral leaching pulp, overflow sent to purify and recover zinc; middle leaching underflow is carried out with waste electrolyte Medium and high acid leaching, after leaching, the ore pulp is flocculated densely with flocculant.

[0057] 3. Main process conditions and results

[0058] 1. Zinc concentrate particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com