A method and application of controlling co-based amorphous fiber to form core-shell structure

A shell structure and fiber technology, which is applied in the field of controlling Co-based amorphous fibers to form a core-shell structure, can solve the problems of poor mechanical properties, low GMI properties and other related performance parameters, and achieve improved tensile breaking strength and excellent soft magnetic properties. and giant magneto-impedance performance, the effect of eliminating internal residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

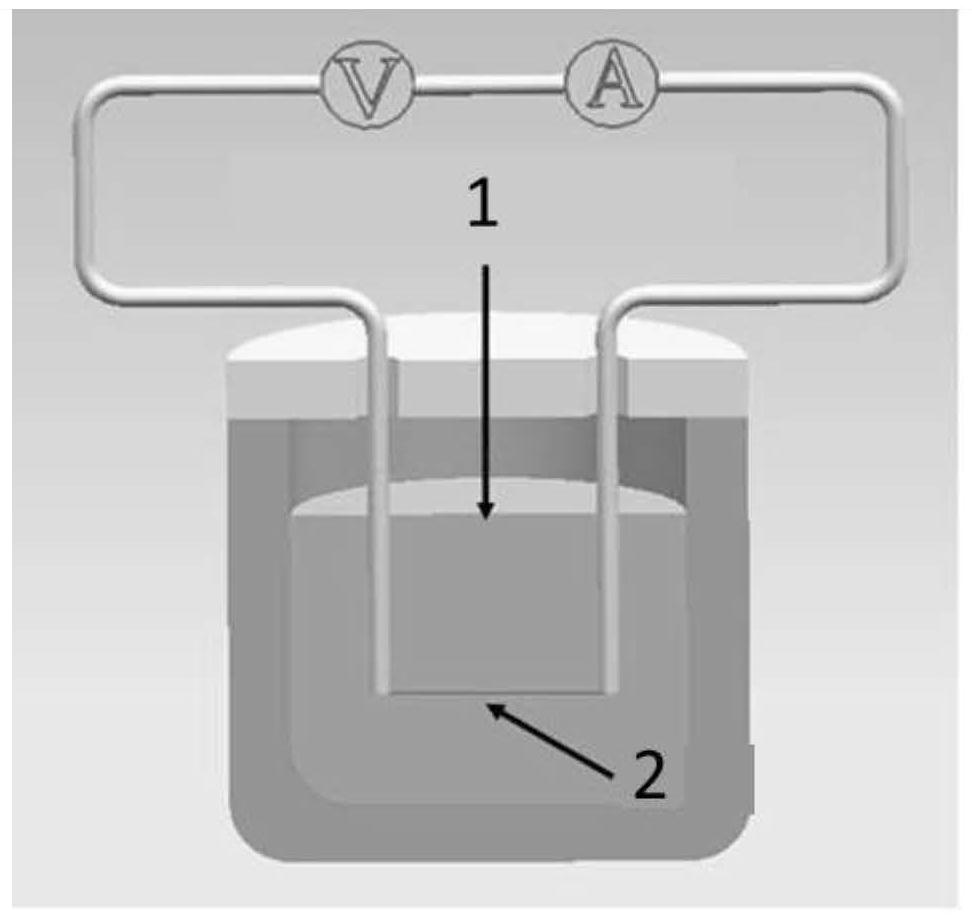

[0031] The embodiment of the present invention is aimed at melt drawing Co 68.15 Fe 4.35 Si 12.25 B 15.25-x Zr x , where x=1, 2 or 3, the special "core-shell" structure of the composite amorphous fiber is structurally characterized. The preparation method is the melt drawing method. The diameter of the amorphous fiber is 35-55um. Carry out in body drawing equipment, vacuum degree is 10 -5 Pa, heating power of power supply is 18-20kW, linear speed of Cu roller is 20-25m / s, feeding speed of master alloy is 30μm / s, and the included angle of roller is about 60°. Stepped DC current annealing was carried out after being prepared into fibers. Embodiments will now be described in detail in conjunction with the accompanying drawings of the present invention. The specific steps for preparing amorphous fibers by the melt drawing method are as follows:

[0032] The master alloy melting and suction casting for melt drawing is carried out on the vacuum magnetron tungsten electric arc...

Embodiment 1

[0041] Example 1. Formation of Co-based amorphous fiber core-shell structure.

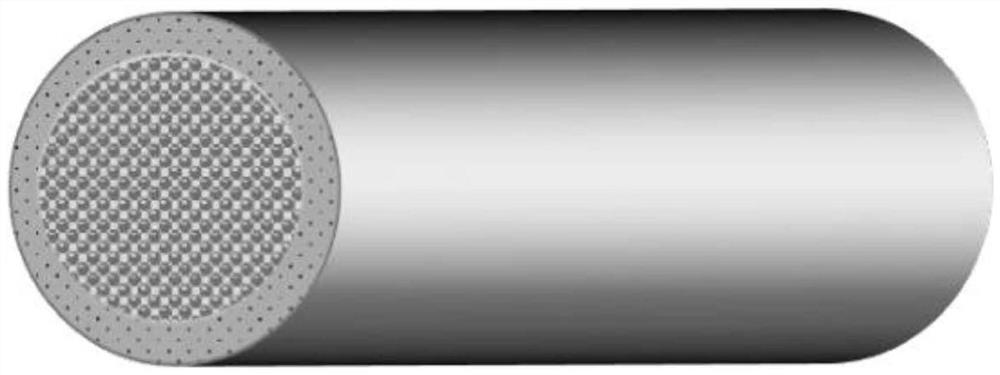

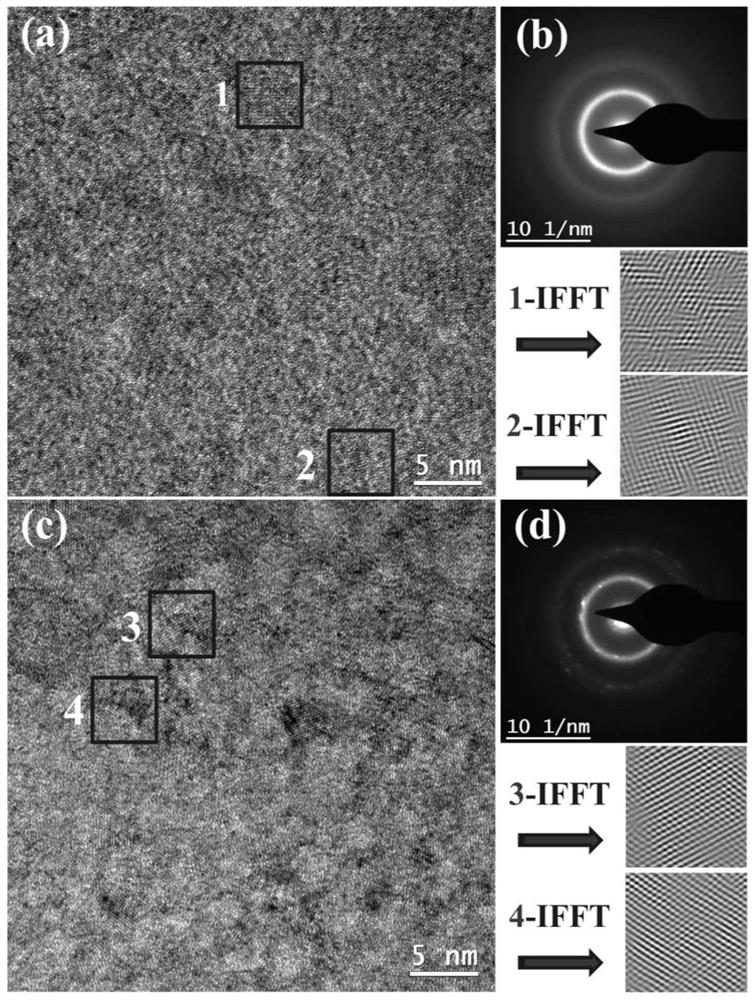

[0042] Preparation of Co by the melt-drawing method 68.15 Fe 4.35 Si 12.25 B 13.25 Zr 1 Amorphous fibers, obtained fibers with a diameter of 45 μm, high roundness and smooth surface. Then stepwise DC current annealing was carried out, and the DC current initial amplitude was 40mA (the current density was 3.0×10 7 A / m 2 ), the step is set to 20mA (the current density is 1.5×10 7 A / m 2 ), the annealing time of each step is 0.5min, and it is terminated at 140mA (the current density is 1.05×10 8 A / m 2 ), complete annealing, and perform high-resolution transmission microscopy analysis on the core of the fiber sample. The Co-based amorphous fiber with a core-shell structure obtained in this example has a diameter of 45 μm, a core diameter of 39 μm, and a shell thickness of 6 μm.

Embodiment 2

[0044] Example 2. Formation of Co-based amorphous fiber core-shell structure.

[0045] Preparation of Co by the melt-drawing method 68.15 Fe 4.35 Si 12.25 B 13.25 Zr 2 Amorphous fibers, obtained fibers with a diameter of 45 μm, high roundness and smooth surface. Then stepwise DC current annealing was carried out, and the DC current initial amplitude was 40mA (the current density was 3.0×10 7 A / m 2 ), the step is set to 20mA (the current density is 1.5×10 7 A / m 2 ), the annealing time of each step is 0.5min, and it is terminated at 80mA (the current density is 5×10 7 A / m 2 ), complete annealing, and perform high-resolution transmission microscopy analysis on the core of the fiber sample. The Co-based amorphous fiber with a core-shell structure obtained in this example has a diameter of 45 μm, a core diameter of 35 μm, and a shell thickness of 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com