Preheating ignition method and device for electric melting furnace

A technology of electric melting and charge, which is applied in the field of preheating ignition method and device of electric melting furnace, can solve problems such as unstable arc combustion, large amount of smoke generated, unbalanced three-phase current, etc., and achieves outstanding substantive features, The effect of fast arc speed and three-phase current balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

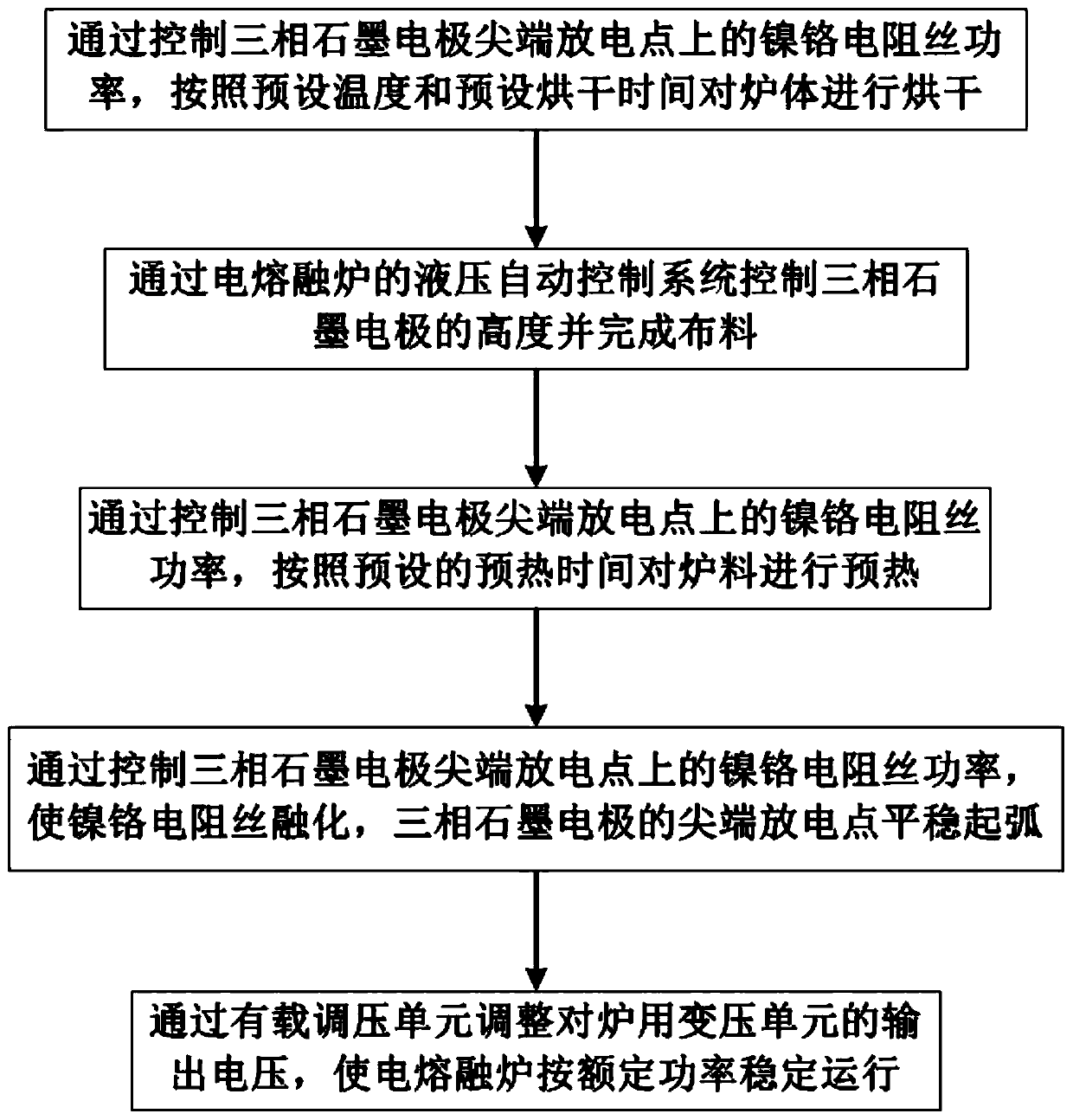

[0037] Such as figure 1 Shown a kind of preheating ignition method that is used for electric fusion furnace, comprises the steps:

[0038] Step 1: By controlling the heating power of the nickel-chromium resistance wire at the tip discharge point of the three-phase graphite electrode, the furnace body is dried according to the preset temperature and preset drying time.

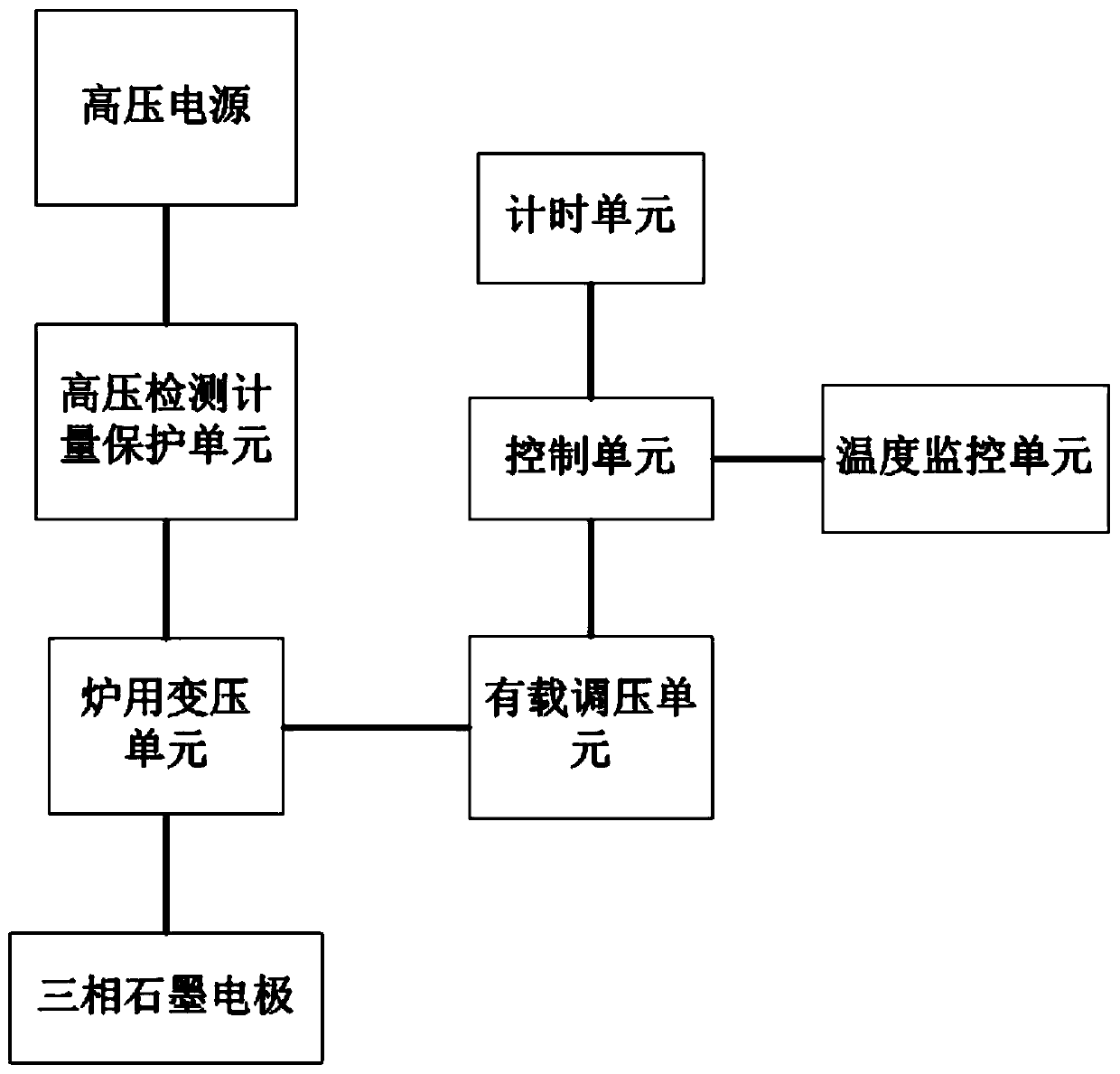

[0039] This step realizes the drying of the furnace body before the operation of the electric melting furnace. At the discharge point at the tip of the three-phase graphite electrode, the three phases are respectively connected (the three-phase graphite electrode head can be drilled with a thread, and the resistance wire joint can be crimped with a screw and a flat pad) 30kW nickel-chromium resistance wire, through the on-load voltage regulation The unit adjusts the low-end voltage to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com