On-site mixed emulsion explosive decoupling charge method and side slope forming blasting method

An emulsion explosive, on-site mixing technology, applied in blasting, earthwork drilling, open-pit mining and other directions, can solve the problems of inability to meet the requirements of construction efficiency and economic indicators, high unit price of slope forming blasting, and high labor intensity, etc. Achieve the effect of improving the degree of mechanized charging operation, reducing construction costs and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Conventional pre-splitting blasting and smooth blasting generally require uncoupled charge. The finished small-diameter explosive rolls are arranged in sequence and bound to skeleton materials such as bamboo chips before being sent into the blast hole. The manufacturing process of uncoupled charge is complicated and difficult. The efficiency is slow, and the consumption of auxiliary consumables is large; therefore, this embodiment provides a method for mixing emulsion explosives on site without coupling charges.

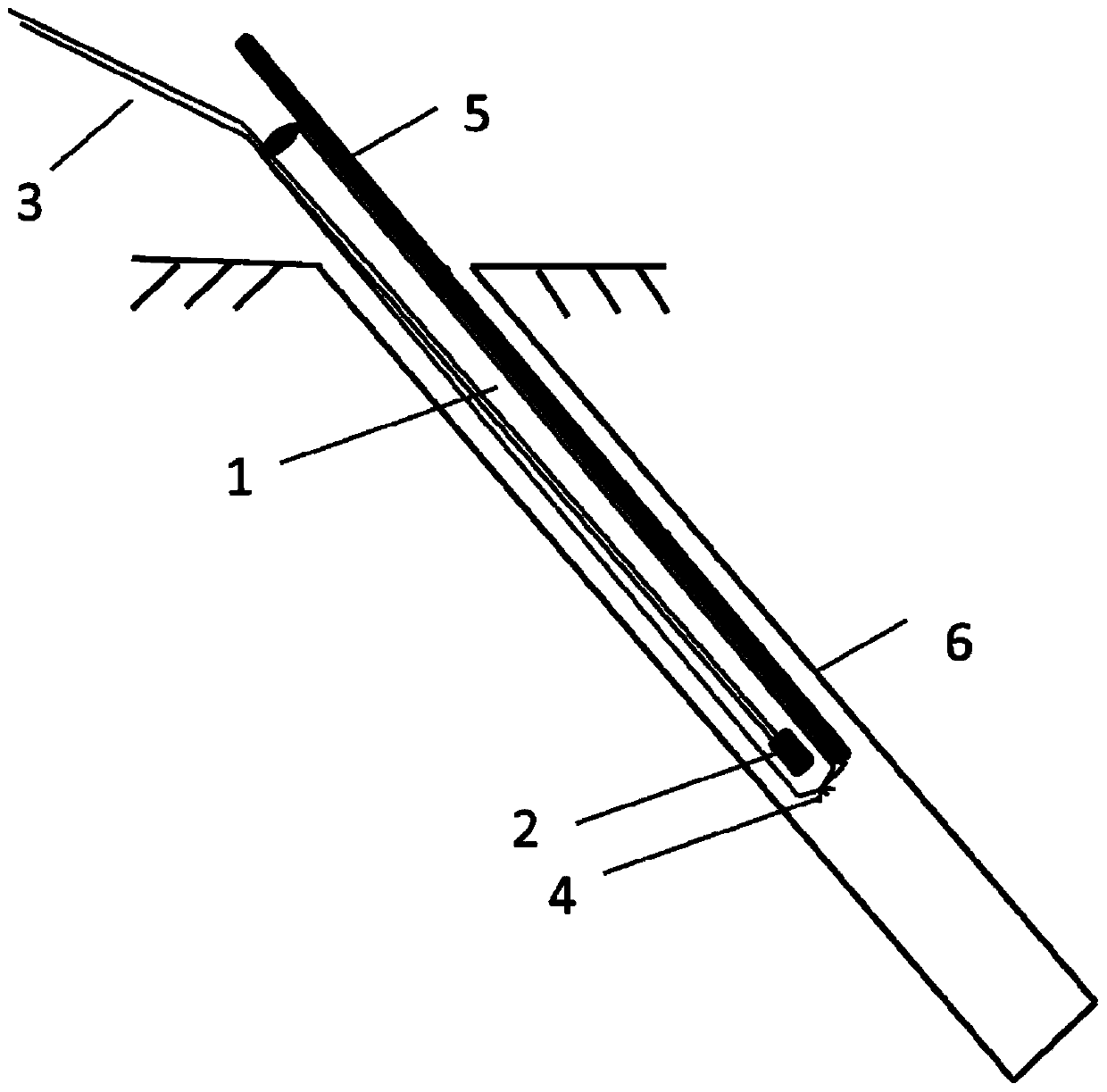

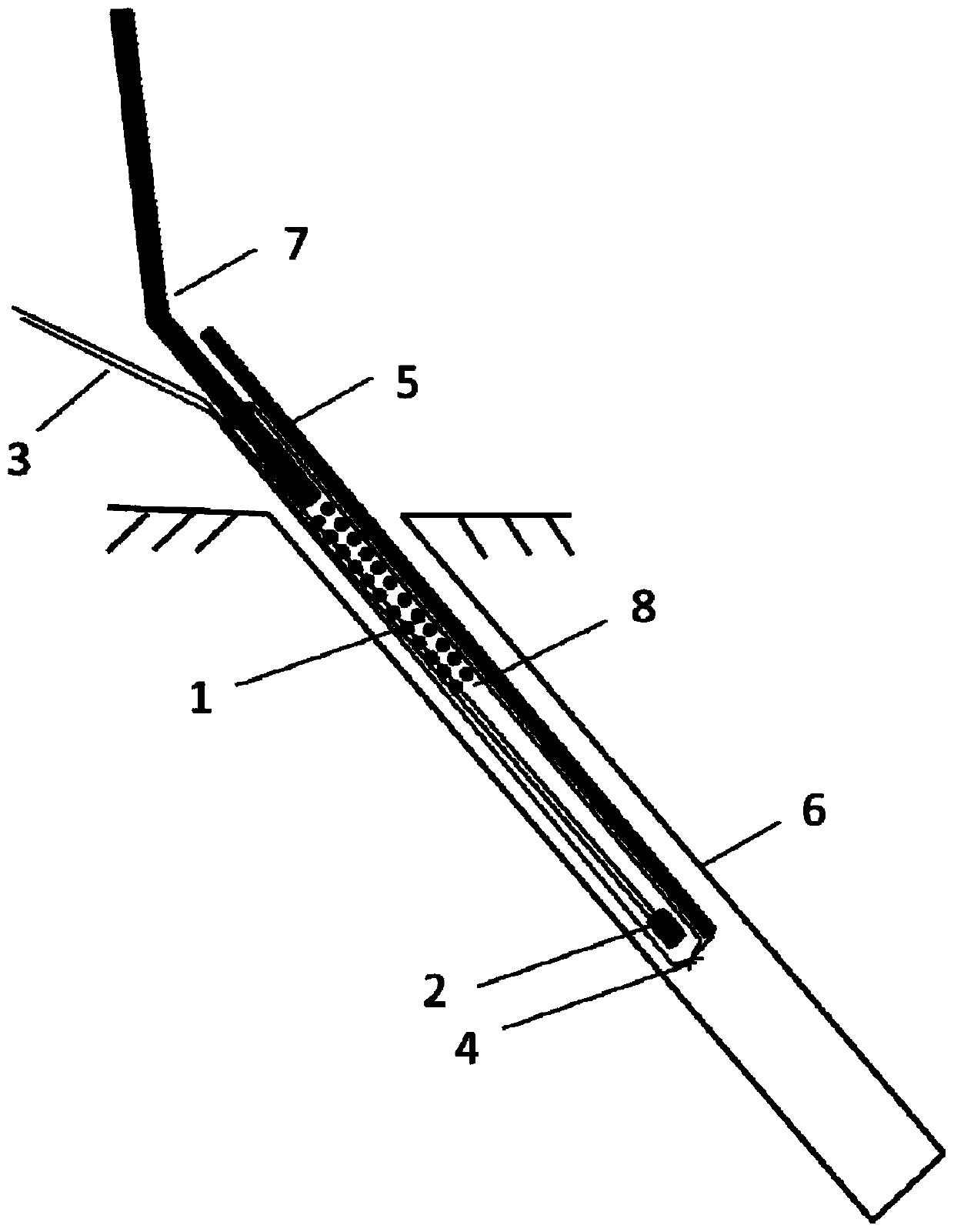

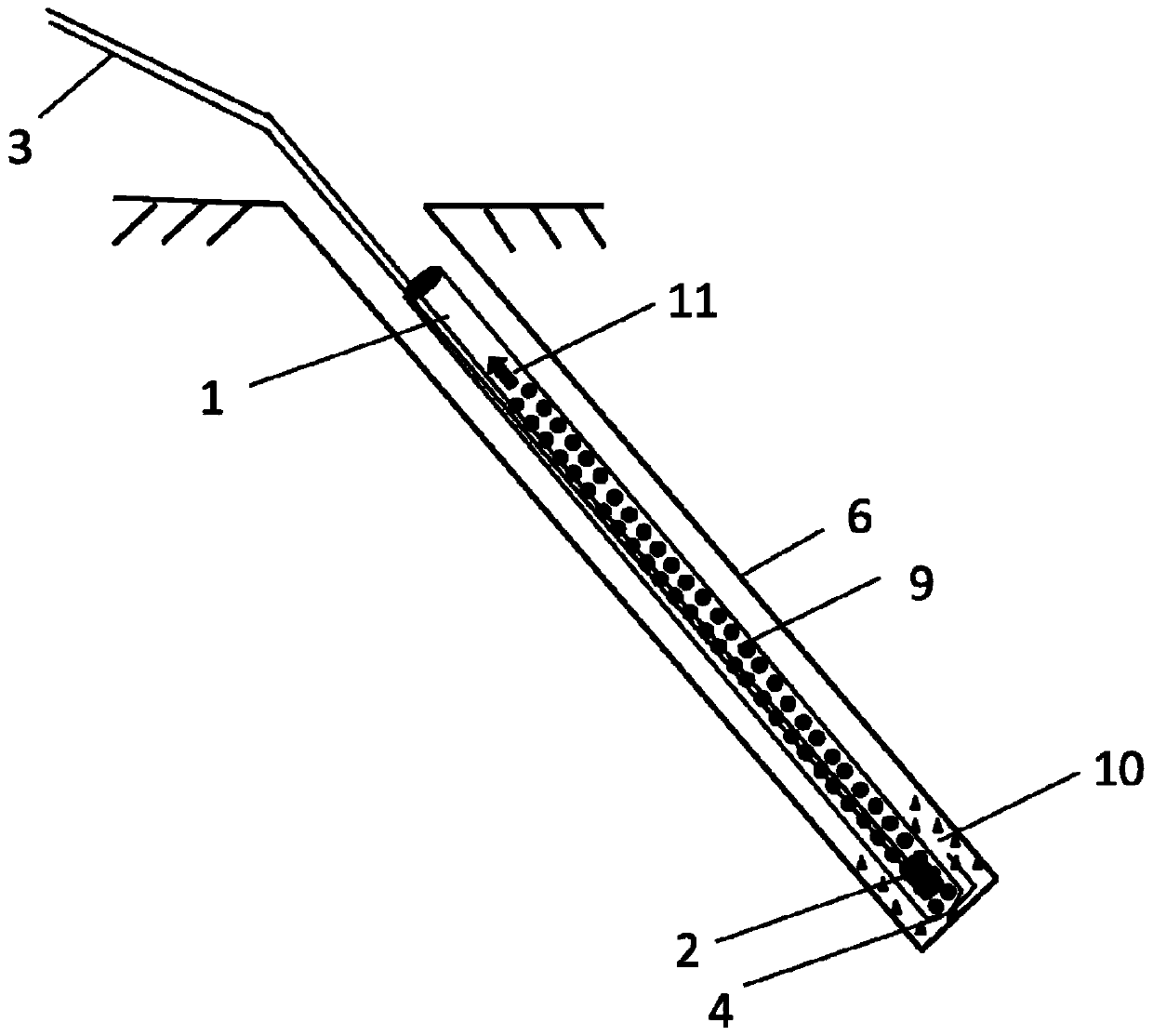

[0047] Such as figure 1 As shown, the uncoupled charge packaging preparation work involved in the on-site mixed emulsified explosive uncoupled charging method of this embodiment includes the following steps:

[0048] 1) According to the requirement of line charge density for pre-splitting blasting or smooth surface blasting, the calculation formula is q=1 / 4πd 2 ρ 0, select or order a certain diameter of the charge hose; where, d is the diameter of the charge...

Embodiment 2

[0063] In the mining process of large-scale open-pit mines, large-scale slope forming control blasting operations are required, including pre-splitting blasting and smooth blasting, to ensure the safety, stability and beauty of the open-pit mine slopes.

[0064] Slope forming controlled blasting needs to strictly control the charge volume of pre-splitting blastholes or smooth blastholes. Uncoupled charge structures are often used, that is, the charge diameter of the charge section in the blasthole is smaller than the diameter of the blasthole, and the charge in the blasthole is controlled. Extended rice charge. Usually, the finished small-diameter explosive coils are used for pre-splitting blasting and smooth blasting construction. The explosive coils are arranged in sequence and bound on skeleton materials such as bamboo chips, and each explosive coil is connected and detonated through the detonating cord. The processing and processing of blasting equipment The charging proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com