Cultivation medium of auricularia auricula

A cultivation substrate and technology of black fungus, which is applied in cultivation, plant cultivation, mushroom cultivation, etc., can solve the problems of low yield and poor quality of black fungus, and achieve neat bacteria production, high substrate utilization rate, and high biological efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

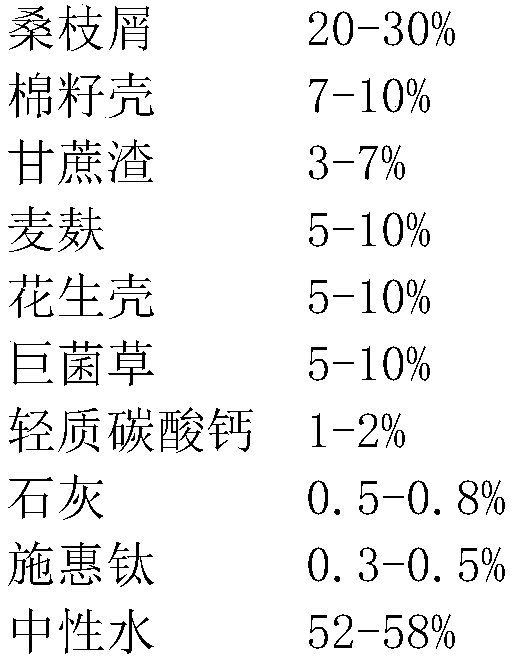

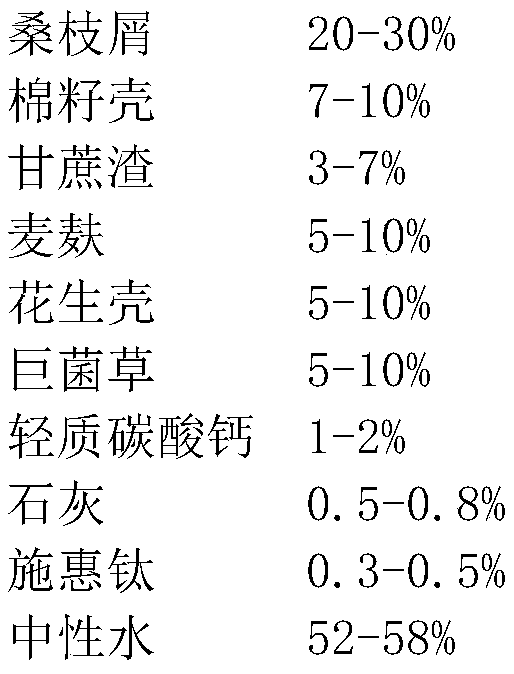

Method used

Image

Examples

Embodiment 1

[0025] (1) 5% by weight of peanut shells and 5% by weight of giant fungus are ground into sawdust-like powder;

[0026] (2) Dry the peanut shells and giant fungus grass made in the above steps, and combine them with the bran of 5% parts by weight, the benefiting titanium of 0.3% parts by weight, the light calcium carbonate of 1% parts by weight, and the Lime, 7% by weight of cottonseed hulls, 3% by weight of bagasse, and 20% by weight of mulberry twigs are mixed, fully stirred, then added with 52% by weight of neutral water, and stirred evenly;

[0027] (3) The well-mixed material is bagged, and each bag is filled with 1.2;

[0028] (4) The bagged material after bagging is sterilized by steam at 97° C. for 12 hours, and after being cooled to below 28° C., the black fungus cultivation substrate is prepared.

[0029] The particle size of the mulberry twigs is 6mm.

Embodiment 2

[0031] (1) 10% by weight of peanut shells and 10% by weight of giant fungus are ground into sawdust-like powder;

[0032] (2) Dry the peanut shells and giant fungus grass made in the above steps, and combine them with 10% by weight of bran, 0.5% by weight of titanium, 2% by weight of light calcium carbonate, and 0.8% by weight of Lime, 10% by weight of cottonseed hulls, 7% by weight of bagasse, and 30% by weight of mulberry twigs are mixed, fully stirred, then added with 58% by weight of neutral water, and stirred evenly;

[0033] (3) Pack the well-mixed material into bags, 1.8kg per bag;

[0034] (4) The bagged material after bagging is sterilized by steam at 120° C. for 16 hours, and after being cooled to below 28° C., the black fungus cultivation substrate is prepared.

[0035] As a preferred technical solution, the particle diameter of the mulberry twigs is 8mm.

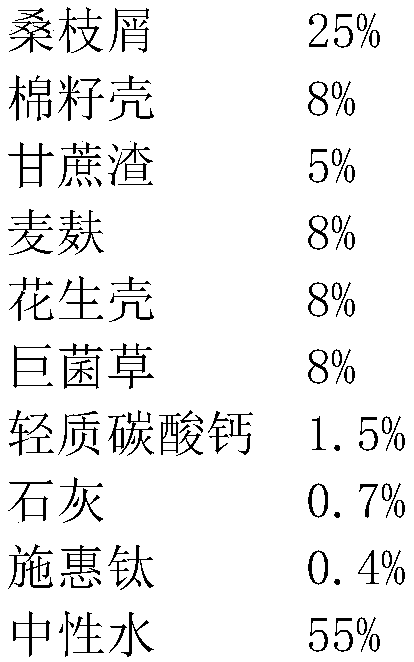

Embodiment 3

[0037] (1) 8% by weight of peanut shells and 8% by weight of giant fungus are ground into sawdust-like powder;

[0038] (2) Dry the peanut shells and giant fungus grass made in the above steps, and combine them with 8% by weight of bran, 0.4% by weight of titanium, 1.5% by weight of light calcium carbonate, 0.7% by weight of Lime, 8% by weight of cottonseed hulls, 5% by weight of bagasse, and 25% by weight of mulberry twigs are mixed, fully stirred, then added with 55% by weight of neutral water, and stirred evenly;

[0039] (3) The well-mixed material is bagged, and each bag is filled with 1.2;

[0040] (4) The bagged material is sterilized by steam at 110° C. for 14 hours at normal pressure, and after being cooled to below 28° C., the black fungus cultivation substrate is prepared.

[0041] The particle size of the mulberry twigs is 7mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com