A device and method for treating mining waste by in-situ carbonization of biomass

A carbonization treatment and treatment method technology, which is applied in the field of biomass in-situ carbonization treatment of mining wastes, can solve the problems of pollutant leakage endangering the environment and human health, prone to invisible hazards, damage to building materials, etc., and achieves accelerated physical The effects of weathering, improving fertility, and regulating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

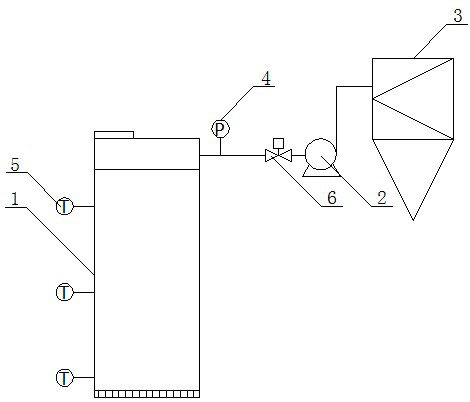

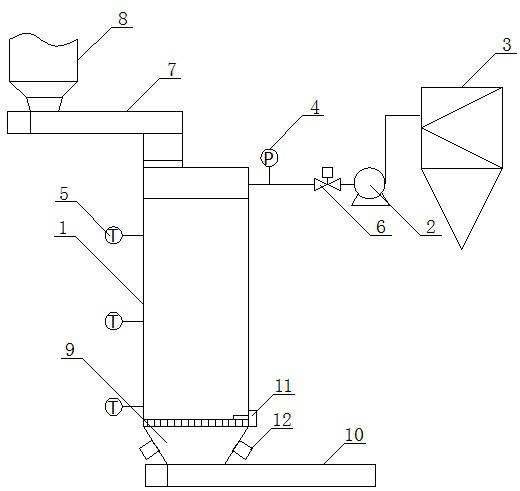

[0044] A treatment method for a device for in-situ carbonization of biomass to treat mining waste, comprising the following steps:

[0045] S1. Mixed material preparation: crush the biomass and mining waste according to the mass ratio of 3:7 and mix them evenly;

[0046] S2. Feeding: Add the mixed material prepared in step S1 into the reactor 1, the feeding rate is 50~150kg / min, and the feeding amount is 2 / 3 of the volume of the reactor 1;

[0047] S3. Carbonization reaction of the mixed material: ignite from the discharge ventilation grid structure, ignite the mixture material, start the fan 2, and the combustion air enters the reactor 1 from the discharge ventilation grid structure and goes upward, and the smoke generated by combustion is blown The fan 2 is introduced into the dust collector 3 for dust removal. During the reaction period, the flow rate of the combustion-supporting air entering the reactor 1 is controlled by the flow valve 6 to be 15L / min. When the temperatur...

Embodiment 2

[0050] A treatment method for a device for in-situ carbonization of biomass to treat mining waste, comprising the following steps:

[0051]S1. Preparation of mixed materials: crush biomass and mining waste in a mass ratio of 3:7, wherein the mining waste is polluted soil and waste earth and stone in a mass ratio of 5:1, crush and mix evenly;

[0052] S2. Feeding: Add the mixed material prepared in step S1 into the reactor 1, the feeding rate is 50~150kg / min, and the feeding amount is 2 / 3 of the volume of the reactor 1;

[0053] S3. Carbonization reaction of the mixed material: ignite the mixed material from the discharge ventilation grid structure, start the fan 2, and the combustion-supporting air enters the reactor 1 from the discharge ventilation grid structure and goes upward, and the smoke generated by combustion is blown The fan 2 is introduced into the dust collector 3 for dust removal. During the reaction period, the flow rate of the combustion-supporting air entering ...

Embodiment 3

[0056] A treatment method for a device for in-situ carbonization of biomass to treat mining waste, comprising the following steps:

[0057] S1. Preparation of mixed materials: crush biomass and mining waste in a mass ratio of 3:7, wherein the mining waste is polluted soil and tailings in a mass ratio of 5:2, pulverize and mix evenly;

[0058] S2. Feeding: Add the mixed material prepared in step S1 into the reactor 1, the feeding rate is 50~150kg / min, and the feeding amount is 2 / 3 of the volume of the reactor 1;

[0059] S3. Carbonization reaction of the mixed material: ignite the mixed material from the discharge ventilation grid structure, start the fan 2, and the combustion-supporting air enters the reactor 1 from the discharge ventilation grid structure and goes upward, and the smoke generated by combustion is blown The fan 2 is introduced into the dust collector 3 for dust removal. During the reaction period, the flow rate of the combustion-supporting air entering the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com