Steel plate machining process used for steel structure production

A processing technology and steel structure technology, which is applied in the field of steel plate cutting, can solve the problems of scalding operators, troublesome replacement, easy loss, etc., and achieve the effect of avoiding scalding, avoiding burning, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

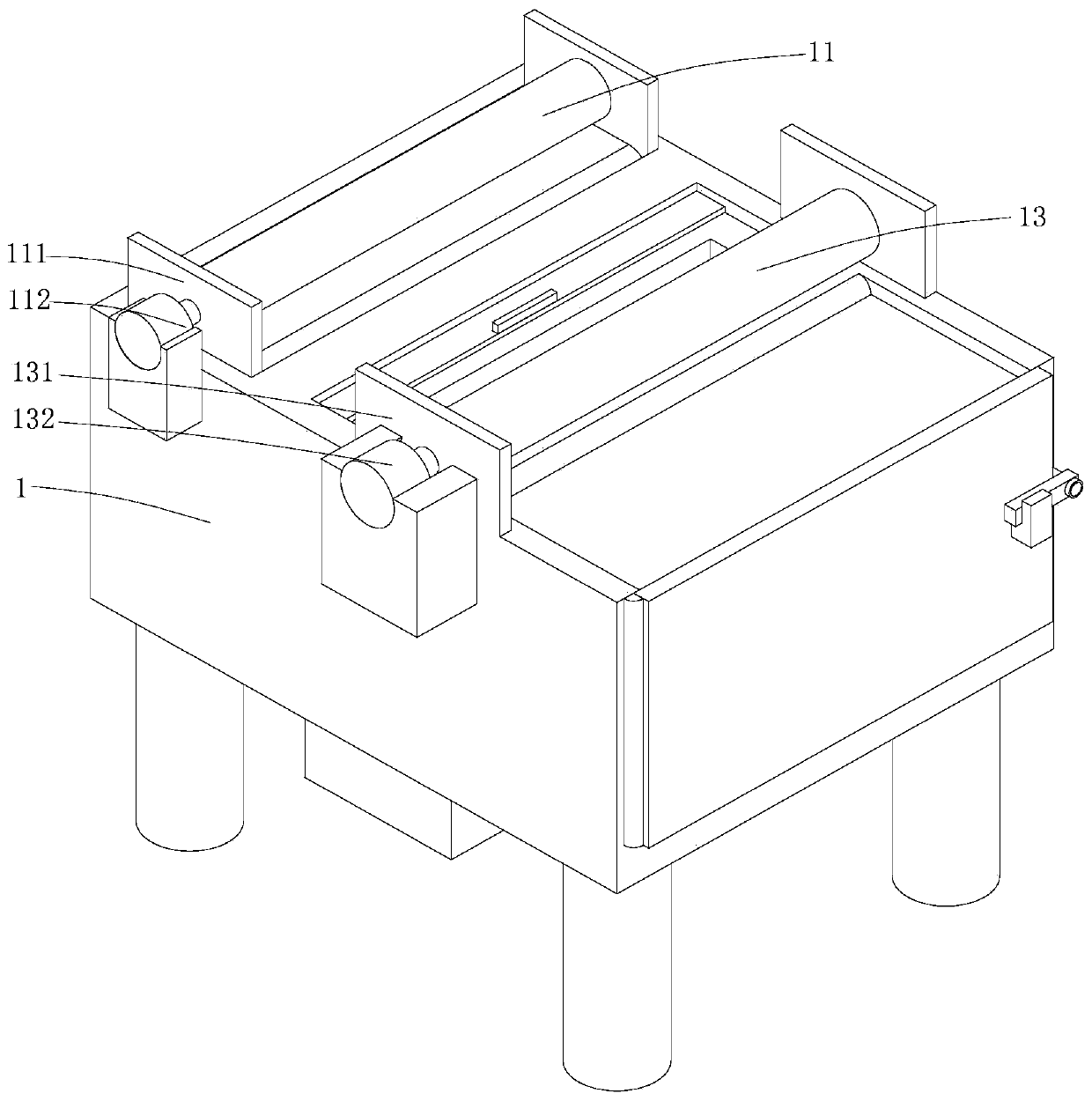

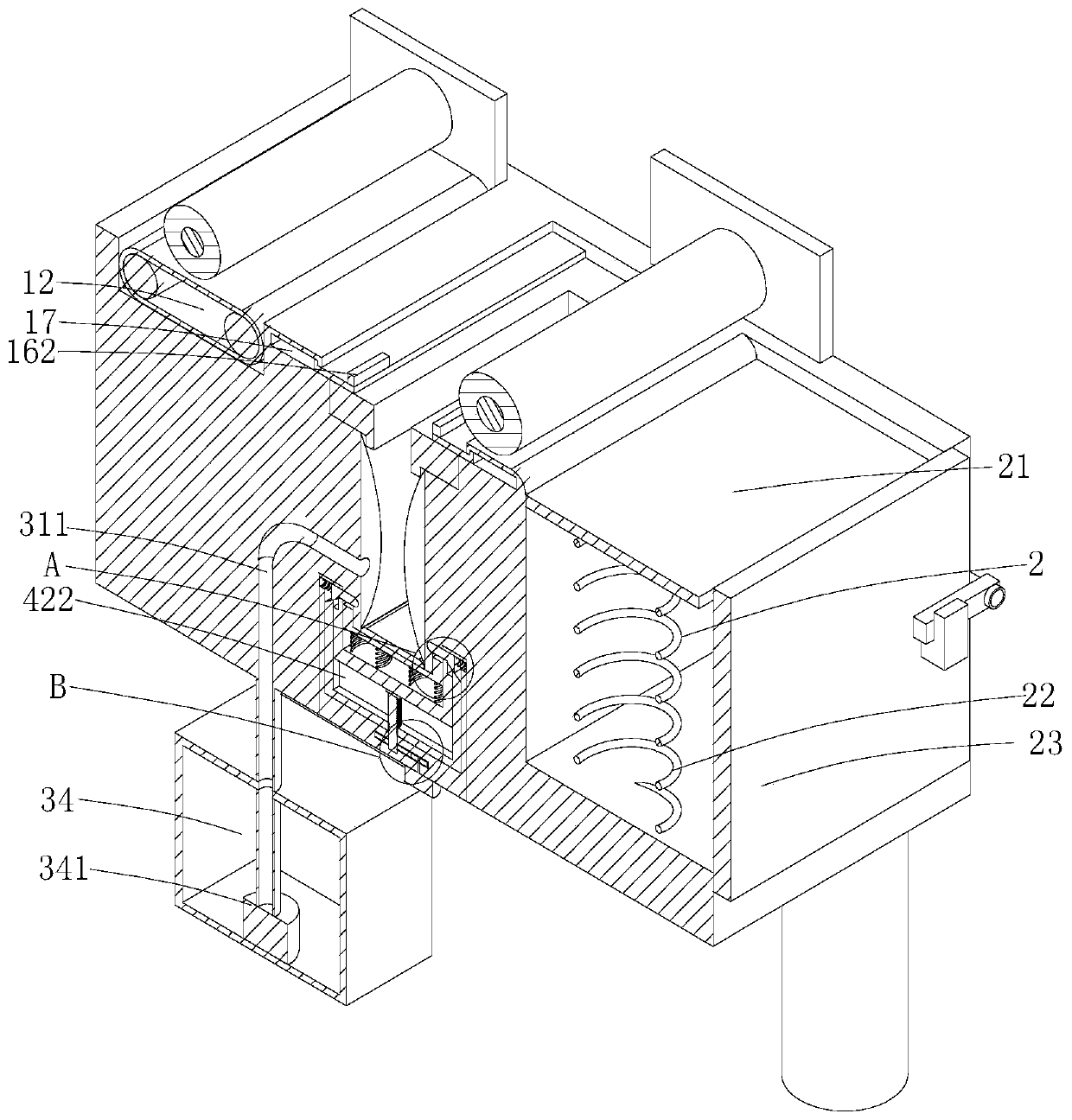

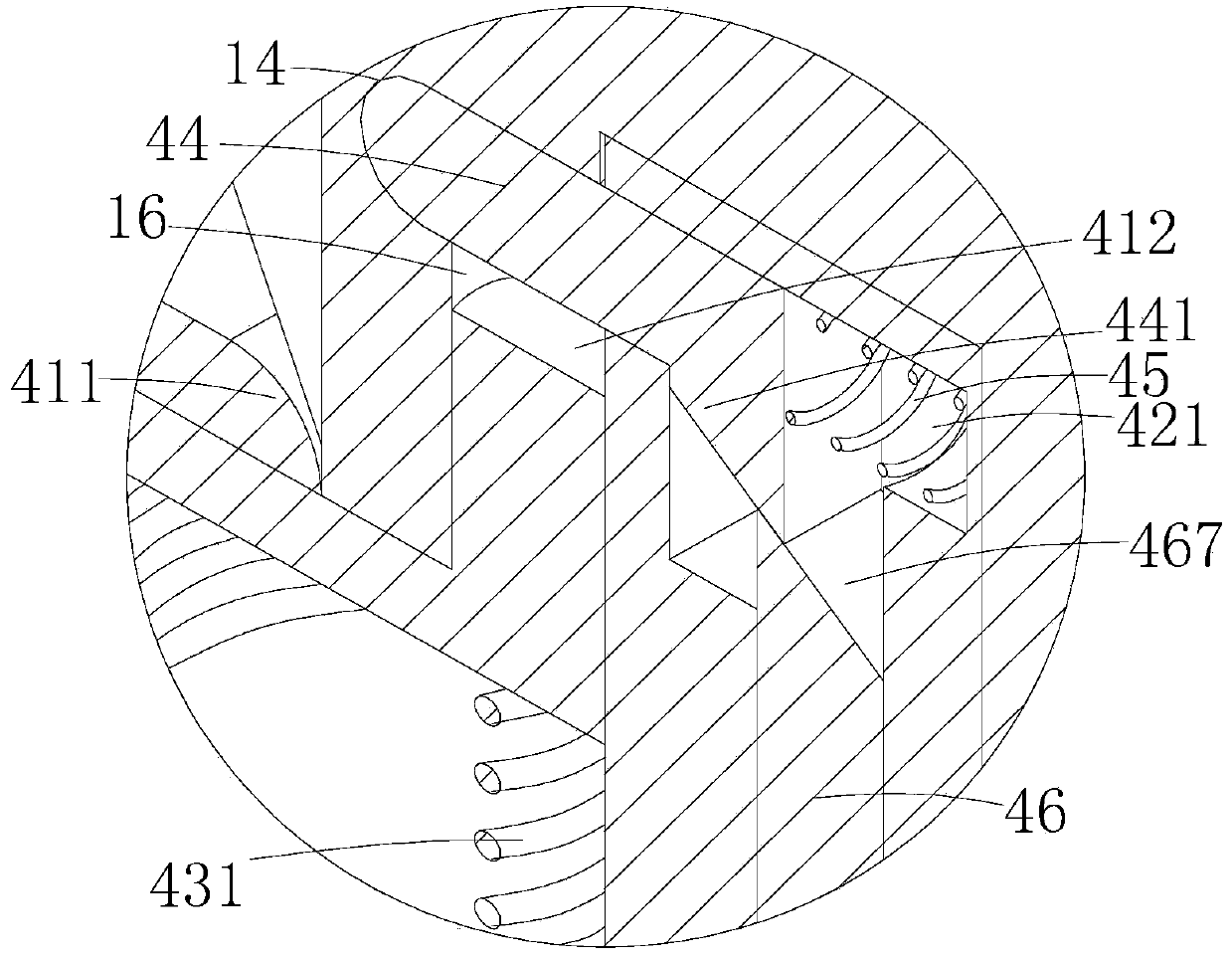

Image

Examples

Embodiment 1

[0023] A steel plate processing technology for steel structure production. The steel plate processing technology includes: a. Lofting: According to the shape and size required by the product construction details or parts and components drawings, the product or parts and components are placed in a ratio of 1:1. The entity is drawn on the lofting platform or flat plate, and the actual length is obtained and made into a sample; b. Cutting: Cut and separate the shape of the lofted and numbered parts from the raw material through the steel plate gas cutting equipment; c. Forming: According to the design requirements, use Processing equipment and certain tooling molds bend the plate or section steel into a certain shape; d. Correction: force the steel to reverse deformation through external force or heating, so that the steel reaches the straight or geometric shape required by the technical standard; e. Edge processing: for To ensure the quality of the weld seam, the edge of the stee...

Embodiment 2

[0032] A steel plate processing technology for steel structure production. The steel plate processing technology includes: a. Lofting: According to the shape and size required by the product construction details or parts and components drawings, the product or parts and components are placed in a ratio of 1:1. The entity is drawn on the lofting platform or flat plate, and the actual length is obtained and made into a sample; b. Cutting: Cut and separate the shape of the lofted and numbered parts from the raw material through the steel plate gas cutting equipment; c. Forming: According to the design requirements, use Processing equipment and certain tooling molds bend the plate or section steel into a certain shape; d. Correction: force the steel to reverse deformation through external force or heating, so that the steel reaches the straight or geometric shape required by the technical standard; e. Edge processing: for To ensure the quality of the weld seam, the edge of the stee...

Embodiment 3

[0035]A steel plate processing technology for steel structure production. The steel plate processing technology includes: a. Lofting: According to the shape and size required by the product construction details or parts and components drawings, the product or parts and components are placed in a ratio of 1:1. The entity is drawn on the lofting platform or flat plate, and the actual length is obtained and made into a sample; b. Cutting: Cut and separate the shape of the lofted and numbered parts from the raw material through the steel plate gas cutting equipment; c. Forming: According to the design requirements, use Processing equipment and certain tooling molds bend the plate or section steel into a certain shape; d. Correction: force the steel to reverse deformation through external force or heating, so that the steel reaches the straight or geometric shape required by the technical standard; e. Edge processing: for To ensure the quality of the weld seam, the edge of the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com