Filling method of special wax

A special wax and filling technology, which is applied in the direction of special packaging objects, packaging, transportation and packaging, etc., can solve the problem of clogged production line, and achieve the effect of high stability, low cost and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

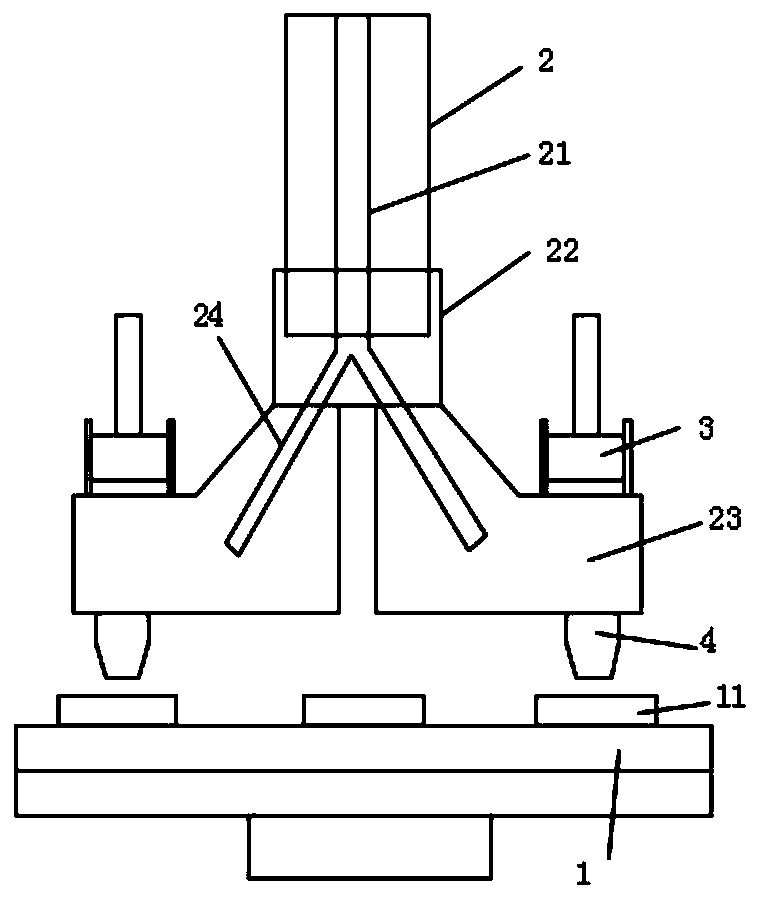

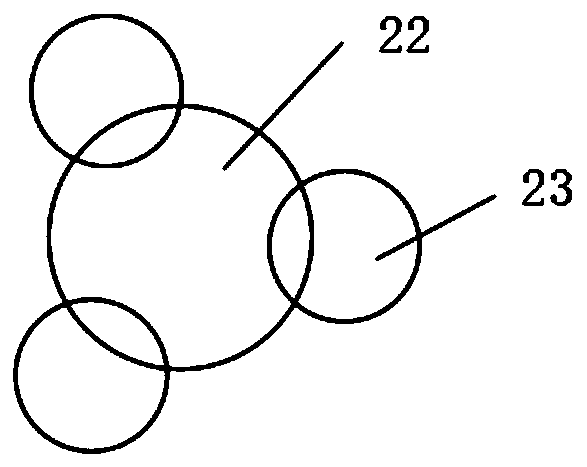

[0040] see Figure 1-Figure 4 , the specific embodiment adopts a novel filling system, and the filling system includes an operating platform 1, a wax delivery pipe 2, and an extruding device 3; the operating platform 1 is a disc-type rotating platform; The inside is provided with a heat pipe 21; the heat pipe 21 is inserted in the center of the wax pipe 2; the tail of the wax pipe 2 is provided with a distribution head 22; each feed pipe 23 of the distribution head 22 is connected with a The corresponding extrusion device 3 is connected; the bottom of the extrusion device 3 is provided with a discharge port 4; the discharge port 4 cooperates with the filling body 11 on the operating platform 1; the extrusion device 3 passes through the cylinder Forming squeezes love pushing wax. The feed pipe 23 is provided with a heat pipe branch 24 .

[0041] Wherein, the edge of the operation platform 1 is provided with the inlet and outlet of the tank body, and the tank body can be opera...

Embodiment 2

[0048] see Figure 2-Figure 5 , the present specific embodiment adopts a novel filling system, and the filling system includes an operating platform 1, a wax delivery pipe 2, and an extruding device 3; the operating platform 1 is a disc-type rotating platform; Contains outer layer 213, insulation layer 212, heat conduction layer 211 and heat transfer layer 210; the inner surface of the heat transfer layer 210 is a polished surface; the heat conduction layer 211 is a metal heat conduction layer, and the temperature rises quickly; the outer layer 213 It is an insulating layer, also a protective cover layer, and has an anti-corrosion function; the tail of the wax feeding pipe 2 is provided with a distribution head 22; each feeding pipe 23 of the distribution head 22 is connected to a corresponding extruding device 3 The bottom of the extruding device 3 is provided with a discharge port 4; the discharge port 4 cooperates with the filling body 11 on the operating platform 1; the wa...

Embodiment 3

[0059] see Figure 2-Figure 4 , Figure 6 This specific embodiment adopts a new type of filling system, and the filling system includes an operation platform 1, a wax delivery pipe 2, and an extruding device 3; the operation platform 1 is a disc-type rotating platform; A heat pipe 21 is provided; the heat pipe 21 is inserted in the center of the wax pipe 2; the wax pipe 2 includes an outer layer 213, a thermal insulation layer 212, a heat conduction layer 211 and a heat transfer layer 210; the heat transfer layer 210 The inner surface of the inner surface is a polished surface; the heat conduction layer 211 is a metal heat conduction layer, and the temperature rises quickly; the outer layer 213 is an insulating layer, which is also a protective cover layer, and has an anti-corrosion function; Distribution head 22; each feed pipe 23 of the distribution head 22 is connected with a corresponding extrusion device 3; the bottom of the extrusion device 3 is provided with a discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com