Lubricant composition and preparation method thereof and preparation of trace lubricant by composition

A lubricant composition and a technology for trace lubricants, which are applied in the field of lubrication, can solve problems such as being unsuitable for the technical field of metal cutting processing, and achieve the effects of remarkable environmental protection effect and consumption saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

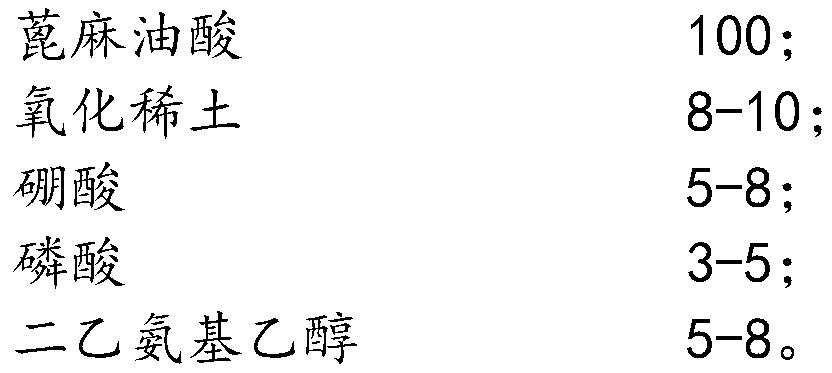

[0037] Step 1: Weigh 100 g of ricinoleic acid, 10 g of lanthanum oxide, 8 g of boric acid, and 5 g of phosphoric acid (effective concentration 85%) and add them together into a stirrer, stir and heat to 120° C., and fully react for 2 hours.

[0038] Step 2: When the temperature is lowered to below 45° C., 8 g of diethylaminoethanol is added and stirred for 2 hours to obtain a translucent substance, which is a lubricant composition.

[0039] The above lubricant composition was subjected to the four-ball extreme pressure test using the GB / T12583 experimental method, and the test result: P D >6080N.

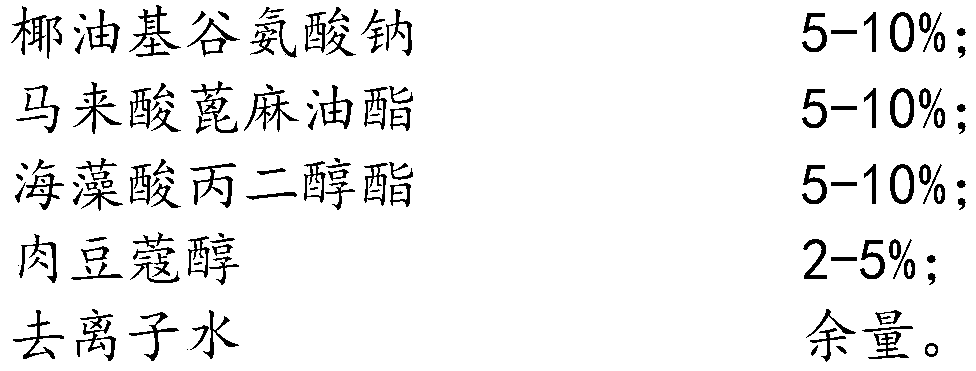

[0040] Take above-mentioned lubricant composition 20g, isononyl isononanoate 30g, sodium cocoyl glutamate 10g, castor oil maleate 10g, propylene glycol alginate 10g, myristyl alcohol 2g, deionized water 18g in When mixed and stirred at 40°C until transparent or translucent, it is a micro lubricant.

[0041] The preparation method of the above-mentioned castor oil maleate: Weigh 92...

Embodiment 2

[0043] Step 1: Weigh 100 g of ricinoleic acid, 8 g of cerium oxide, 5 g of boric acid, and 6 g of phosphoric acid (50% effective concentration) and add them together into a stirrer, stir and heat to 100° C., and fully react for 3 hours.

[0044] Step 2: When the temperature is lowered to below 45° C., add 5 g of diethylaminoethanol and stir for reaction for 1 hour to obtain a translucent substance, which is a lubricant composition.

[0045] Take above-mentioned lubricant composition 100g, isononyl isononanoate 400g, sodium cocoyl glutamate 50g, castor oil maleate 50g, propylene glycol alginate 50g, myristyl alcohol 50g, deionized water 300g in When mixed and stirred at 60°C until transparent or translucent, it is a micro lubricant.

[0046] The preparation method of the above-mentioned castor oil maleate: Weigh 929.26g (1mol) of castor oil and 116.07g (1mol) of maleic acid into the reaction kettle together, stir and heat to 200°C, fully react for 8 hours, and drain 2 times, a...

Embodiment 3

[0048] Step 1: Weigh 100 g of ricinoleic acid, 9 g of lanthanum oxide, 6 g of boric acid, and 8 g of phosphoric acid (50% effective concentration) and add them together into a stirrer, stir and heat to 110° C., and fully react for 2.5 hours.

[0049] Step 2: When the temperature is lowered to below 45° C., add 6 g of diethylaminoethanol and stir for 1.5 hours to react to obtain a translucent substance, which is a lubricant composition.

[0050] Take above-mentioned lubricant composition 125g, isononyl isononanoate 350g, sodium cocoyl glutamate 80g, castor oil maleate 70g, propylene glycol alginate 70g, myristyl alcohol 30g, deionized water 275g in When mixed and stirred at 50°C until transparent or translucent, it is a micro lubricant.

[0051]The preparation method of the above-mentioned castor oil maleate: Weigh 929.26g (1mol) of castor oil and 116.07g (1mol) of maleic acid into the reaction kettle together, stir and heat to 220°C, fully react for 6 hours, and drain 1 hour i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com