Engineering neurospora crassa, preparation method thereof and application of neurospora crassa

A technology of engineering bacteria and bacteria, applied in the directions of botanical equipment and methods, biochemical equipment and methods, applications, etc., can solve the problem that the cell wall of plants cannot be rapidly degraded, and achieve the effect of reducing the fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

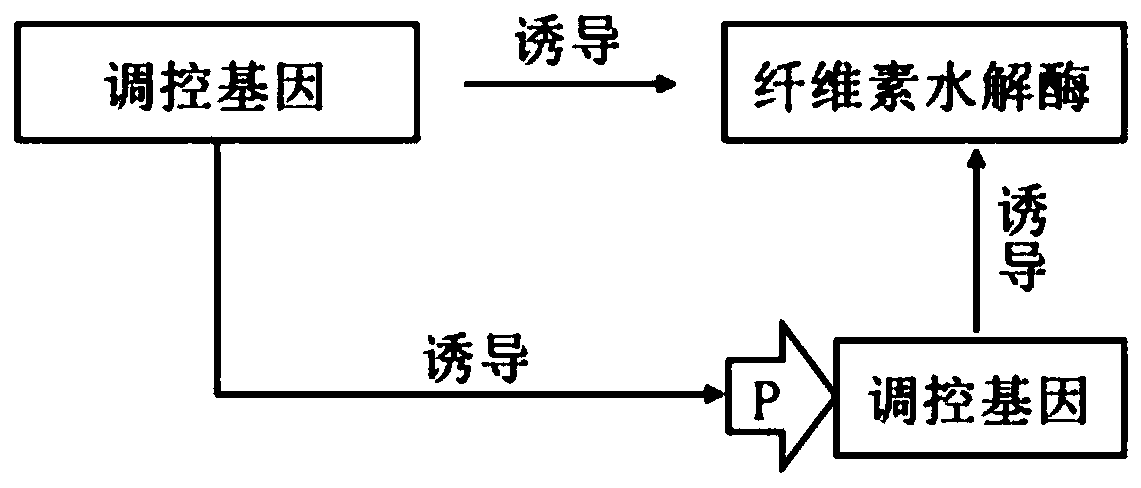

Method used

Image

Examples

Embodiment 1

[0013] Example 1 Construction of Neurospora crassa strains with positive feedback regulation of cellulase genes (1) extract the total RNA of Neurospora crassa (Neurospora crassa) FGSC 4200 (purchased from Fungal Genetics Stock Center), reverse transcription cDNA was generated and used as a template, using the upstream primer 5'-GAGGCTGAAGCTGAATTCATGGCACCATCAATGTCG-3' and the downstream primer 5'-ATGAGTTTTTGTTTCTAGAGTAGGTGTACCCATCCATA-3' to amplify the cellulase regulatory gene sequence clr -2; PCR amplification conditions are as follows: pre-denaturation at 95°C for 5 minutes, followed by 30 cycles at 95°C for 30 seconds, 56°C for 30 seconds, and 72°C for 2.5 minutes; finally, extension at 72°C for 10 minutes.

[0014] (2) The PCR product obtained in the above step (1) was purified using a small DNA purification kit (purchased from Tiangen Company). At the same time, the vector pPICZa-A was digested with EcoRI and XbaI, and the corresponding vector fragment was recovered using...

Embodiment 2

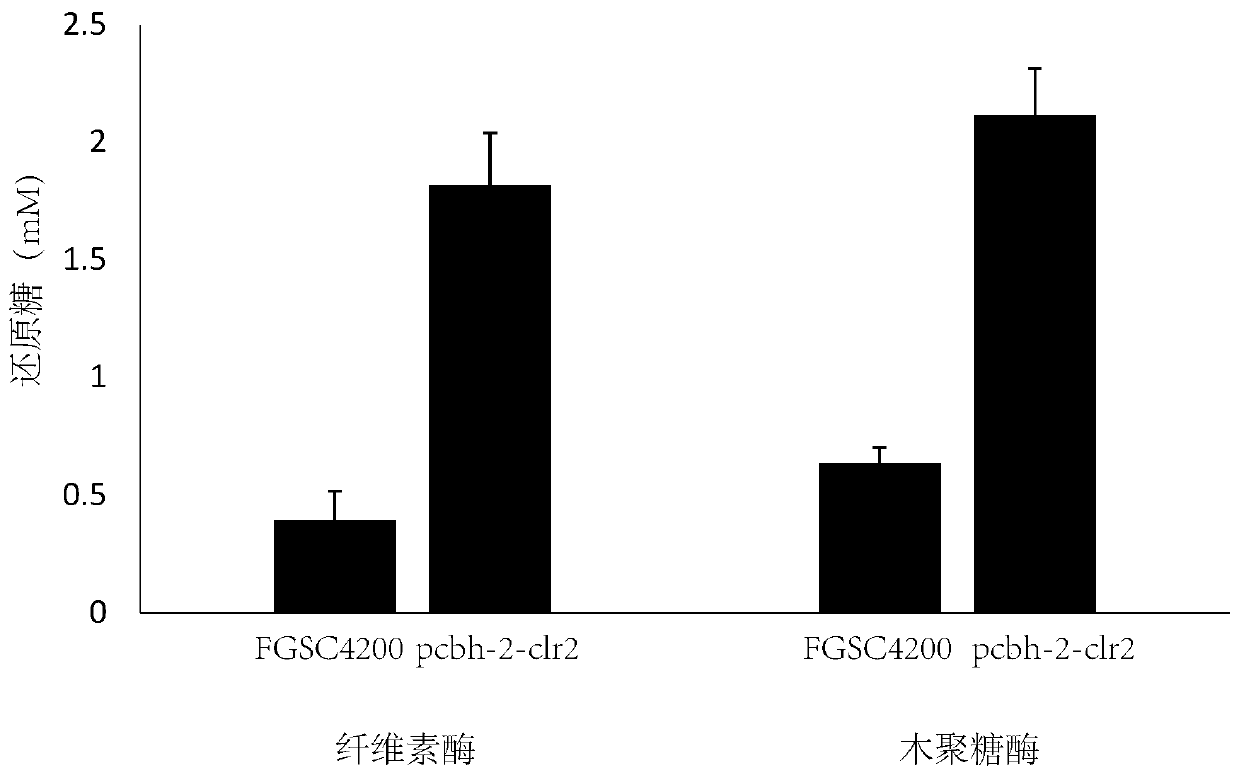

[0019] The comparison of cellulase and xylanase activity of embodiment 2 Neurospora crassa bacterial strains

[0020] 1. Analysis of clr-2 protein expression

[0021] Neurospora crassa (Neurospora crassa) Pcbh-2-clr2 was inoculated into vogel's medium, with 0.5% CMC as the sole carbon source, and cultured at 30°C for 5 days. The cells were disrupted with glass beads, and the expression of clr-2 protein (antibody: c-myc) was detected by western blot. The results showed that clr-2 was highly expressed under this condition. Its protein size is about 91 kDa.

[0022] 2. Analysis of cellulase activity

[0023]Configure 50mL Vogel's medium, use the treated straw as the single carbon source, inoculate N.crassa FGSC4200 and Neurospora crassa (Neurospora crassa) Pcbh-2-clr2 into the medium (the final concentration of spores is 10 6 individual / mL). Take 500 uL of the day 3 culture supernatant, centrifuge, and transfer the supernatant to a new storage tube. Take 100uL of supernatan...

Embodiment 3

[0026] Example 3 The effect of accelerating the composting of straw after adding the mixed bacterial solution

[0027] 1. Analysis of temperature shock period

[0028] In the fermentation process without the addition of the bacterial liquid, there is a period of temperature fluctuations in the early fermentation stage. Usually when the temperature reaches 70 degrees Celsius, the compost pile needs to be turned over to increase sufficient oxygen and maintain the normal operation of microorganisms. temperature. It is generally about 7 days from the beginning of fermentation to when the temperature reaches 70 degrees Celsius. The period from the first turning to the second turning is also about 7 days, the temperature from the second turning to the third turning is about 10 days, and the period from the third to the fourth is about 15 days. The overall temperature shock period is around 40.

[0029] However, after the bacterial solution was added, the time from the beginning t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com