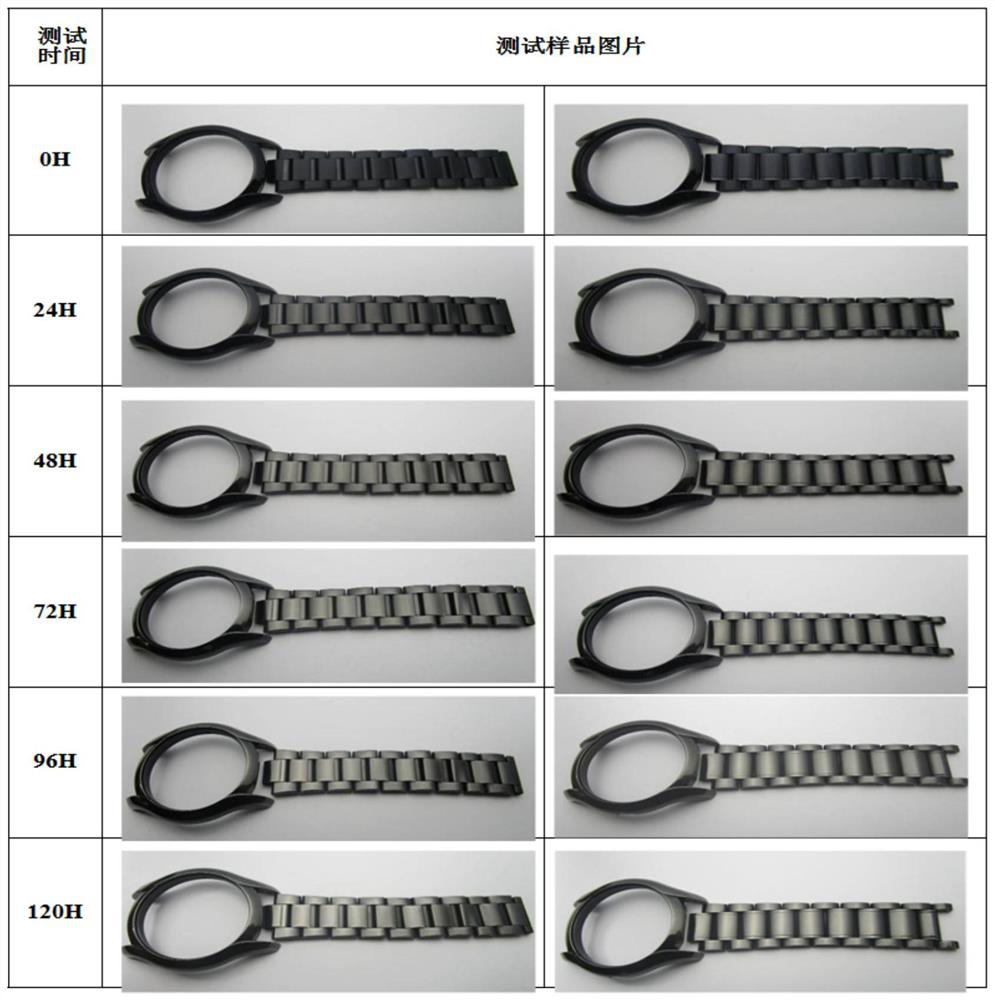

A kind of ultra-black wear-resistant coating and preparation method thereof

A manufacturing method and technology of wear-resistant coating, applied in the direction of coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of black color and wear-resistant performance that cannot meet high requirements, and achieve low cost , Hardness and wear resistance improvement, the effect of high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. The base material is ultrasonically cleaned, heated and vacuumed in the coating chamber, and the holding temperature is 200-230°C;

[0048] 2. The vacuum reaches 6.0*10-3~8.0*10-3Pa, and Ar gas is introduced to make the air pressure reach 0.1~0.2Pa, the bias voltage is -300~-400V, and ion cleaning is performed for 1~3 circles.

[0049] 3. Adjust the Ar gas intake to make the air pressure reach 0.3-0.4Pa, set the bias voltage to -50--100V, turn on the intermediate frequency coating power supply current to deposit pure Ti layer, and the titanium target current is 28-32A.

[0050] 4. Introduce N2 gas, the amount of N2 increases from 30sccm to 200sccm, the air pressure is 0.30~0.50Pa, and the Ti, Al, Si and W targets are turned on at the same time, and the target currents are respectively Ti=28~32A, Al=13~17A, Si =12~18A, W=3~7A, deposit WTiAlSiN layer for 30~40 minutes.

[0051] 5. Introduce N2 gas, the amount of N2 increases from 100sccm to 200sccm, the pressure is 0....

Embodiment 2

[0055] 1. The base material is ultrasonically cleaned, heated and evacuated in the coating chamber, and the heat preservation temperature is 210°C;

[0056] 2. The vacuum reaches 6.0*10-3~8.0*10-3Pa, and Ar gas is introduced to make the air pressure reach 0.1~0.2Pa, the bias voltage is -300~-400V, and ion cleaning is performed for 1~3 circles.

[0057] 3. Adjust the Ar gas intake to make the air pressure reach 0.3-0.4Pa, set the bias voltage to -50--100V, turn on the Ti target, and deposit a pure Ti layer.

[0058] 4. Infuse N2 gas, the pressure is 0.30-0.40Pa, open the Ti, Al, Si and W targets at the same time, and deposit the WTiAlSiN layer for 30 minutes.

[0059] 5. Infuse N2 gas, adjust the gas pressure to 0.4-0.5 Pa, open the Ti, Al, Si and W targets at the same time, and deposit the WTiAlSiN layer for 65 minutes.

[0060] 6. Turn off the TiAlSi target, turn off N2, fill in C2H2, the air pressure is 0.3pa, and turn on the W target at the same time, deposit the WC layer,...

Embodiment 3

[0062] 1. The base material is ultrasonically cleaned, heated and evacuated in the coating chamber, and the heat preservation temperature is 210°C;

[0063] 2. The vacuum reaches 6.0*10-3~8.0*10-3Pa, and Ar gas is introduced to make the air pressure reach 0.1~0.2Pa, the bias voltage is -300~-400V, and ion cleaning is performed for 1~3 circles.

[0064] 3. Adjust the Ar gas intake to make the air pressure reach 0.3-0.4Pa, set the bias voltage to -50--100V, turn on the Ti target, and deposit a pure Ti layer.

[0065] 4. Infuse N2 gas, adjust the air pressure to 0.30-0.40Pa, open the Ti, Al, Si and W targets at the same time, and deposit the WTiAlSiN layer for 35 minutes.

[0066] 5. Infuse N2 gas, adjust the gas pressure to 0.4-0.5 Pa, open the Ti, Al, Si and W targets at the same time, and deposit the WTiAlSiN layer for 70 minutes.

[0067] 6. Turn off the TiAlSi target, turn off N2, fill in C2H2, the air pressure is 0.4pa, turn on the W target at the same time, deposit the WC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com