Multi-angle automatic tracking wall surface colored drawing machine

An automatic tracking and multi-angle technology, applied in the field of color painting machines, can solve the problems of ink staining on the wall, damage to the nozzle, and lack of overall effect, etc., and achieve the effect of good adhesion, smooth and beautiful painting, and prolonging the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment a

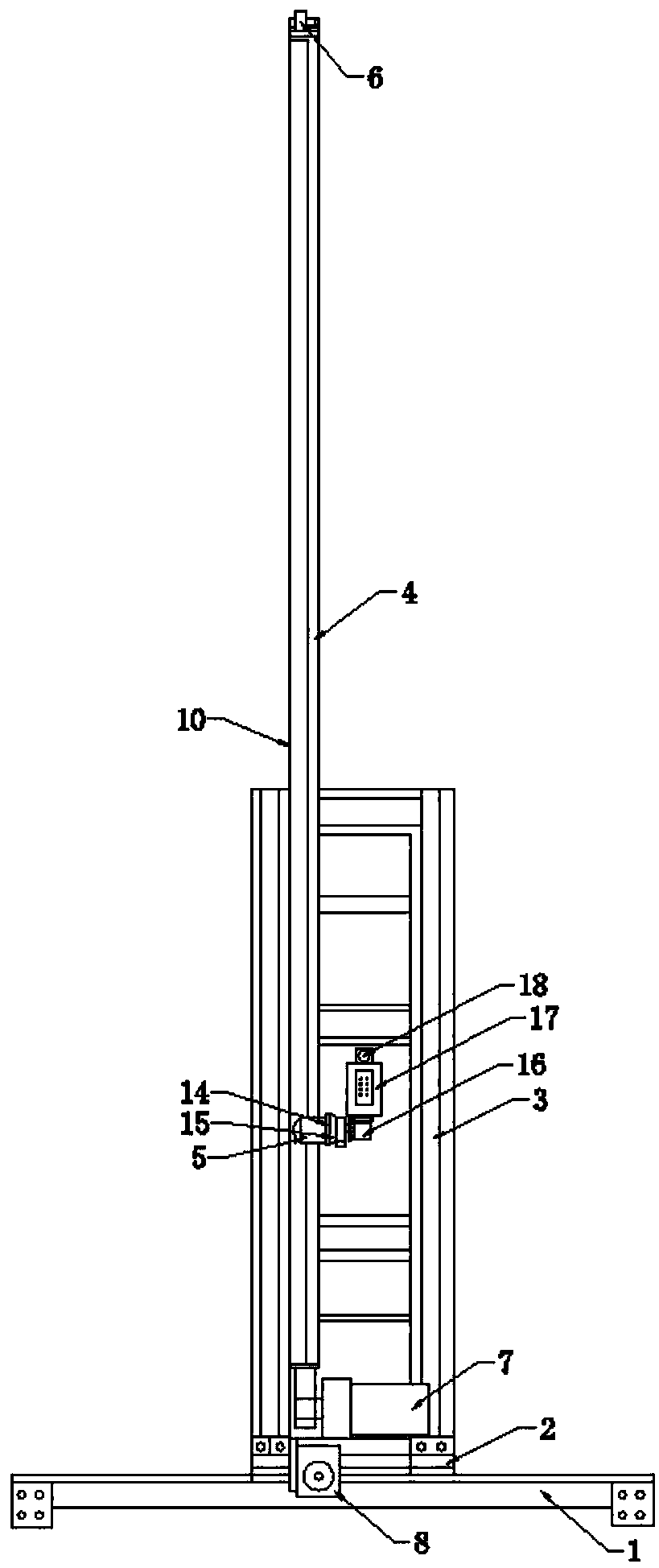

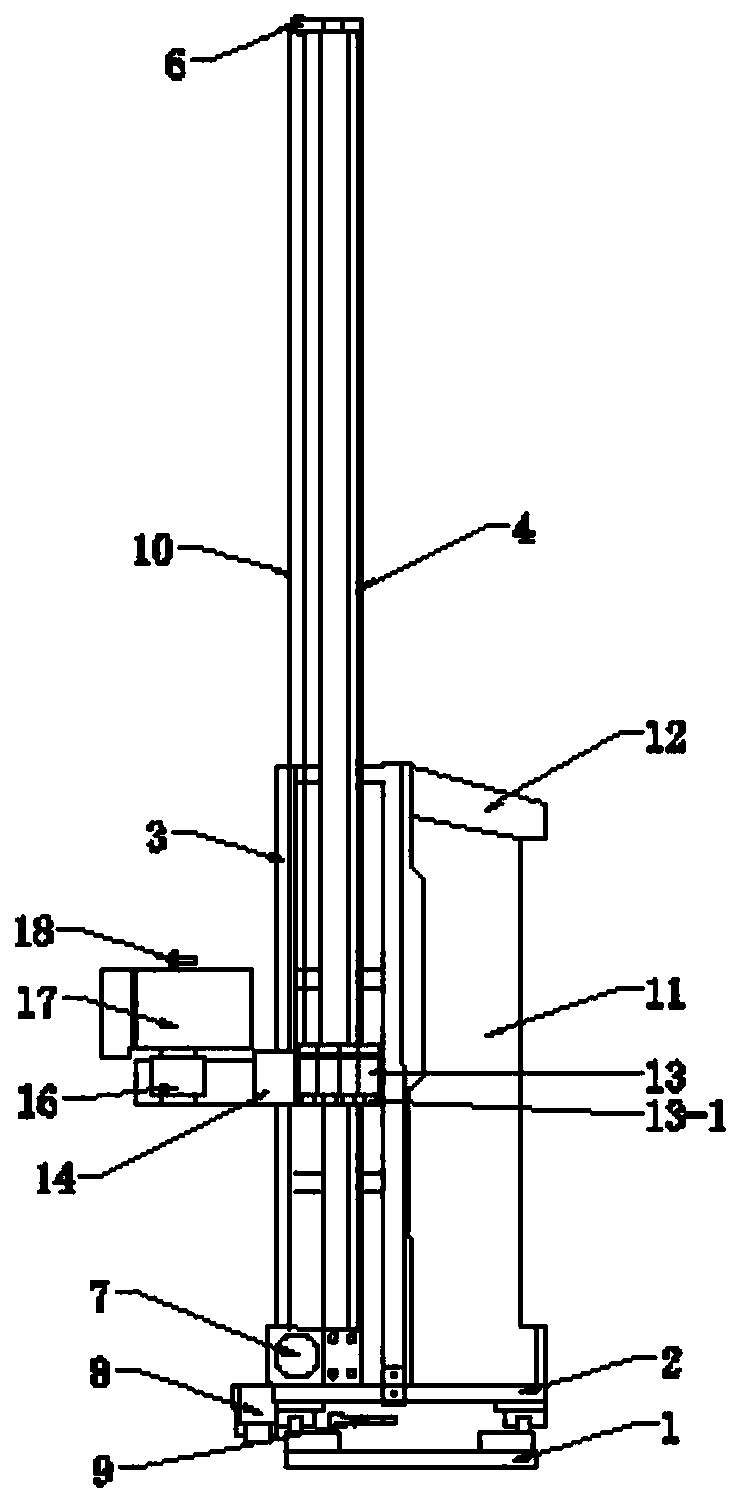

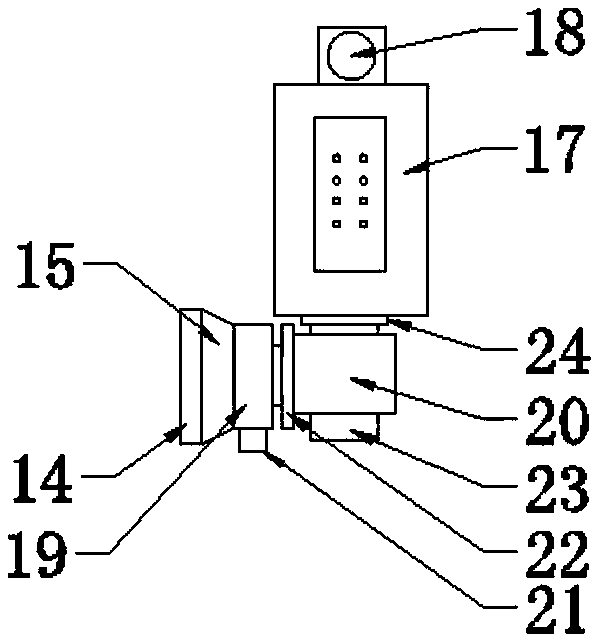

[0026] see figure 1 with figure 2 , a multi-angle automatic tracking wall painting machine, including a base 1, a support frame 2, a bracket 3, a vertical rail 4, a movable slider 5, a fixed pulley 6, a vertical travel motor 7, a lateral travel motor 8, and a pinion 9. Belt 10, control box 11, control panel 12, ink cartridge 13, fixed plate 14, electric slider 15, rotary device 16, inkjet device 17, laser scanner 18, characterized in that: the base 1 is provided with Support frame 2, support frame 2 is connected with the track sliding on the base 1 by slide block, described support frame 2 is provided with support 3, and described vertical track 4 is positioned on support frame 2 and is fixedly connected with support 3 one side, The top of the vertical track 4 is provided with a fixed pulley 6, and the bottom end is fixedly equipped with a vertical travel motor 7, and the horizontal travel motor 8 is fixedly installed on the bottom end of the support frame 2 side by the moto...

Embodiment 1

[0031] In the multi-angle automatic tracking wall painting machine described in this embodiment, the painting paint contained in the ink cartridge (13) is composed of the following components in parts by weight: 20 parts of acrylic emulsion, 18 parts of silicon powder , 16 parts of zinc sulfide, 22 parts of pigments, 11 parts of fillers, 0.8 parts of wetting agents, 6 parts of thickeners, 0.4 parts of defoamers, 8 parts of film-forming aids, 0.9 parts of pH regulators, pre-dispersed dyes 5 parts of dispersion liquid, 100 parts of water.

[0032] Wherein, the filler is composed of the following components in parts by weight: 30-45 parts of chondroitin sulfate, 10-20 parts of silicomanganese slag, 15-20 parts of alkaline earth metal sulfate, 35-40 parts of phosphogypsum, 20-20 parts of propylene glycol 25 parts and 20-25 parts of hydroquinone;

[0033] The thickener is composed of the following components in parts by weight: 55-75 parts of acrylic acid, 15-25 parts of polyethyl...

Embodiment 2

[0039] In the multi-angle automatic tracking wall painting machine described in this embodiment, the painting paint contained in the ink cartridge (13) is composed of the following components in parts by weight: 36 parts of acrylic emulsion, 24 parts of silicon powder , 12 parts of zinc sulfide, 30 parts of pigment, 4 parts of filler, 1 part of wetting agent, 14 parts of thickener, 0.2 part of defoamer, 10 parts of film-forming aid, 0.6 part of pH regulator, pre-dispersed dyeing agent 8 parts of dispersion liquid, 80 parts of water.

[0040] Others are the same as embodiment 1.

[0041] Get above-mentioned painted paint and measure its viscosity to be 100mPa·S, and average particle size is 3.0µm. The paint was sampled and sprayed to draw a picture, and the SEM image of the drawing sample was tested. It was observed that the surface morphology was smooth, the arrangement was orderly, the particle size was uniform, and the thickness was about 2.0 µm. The painted wall pictures ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com