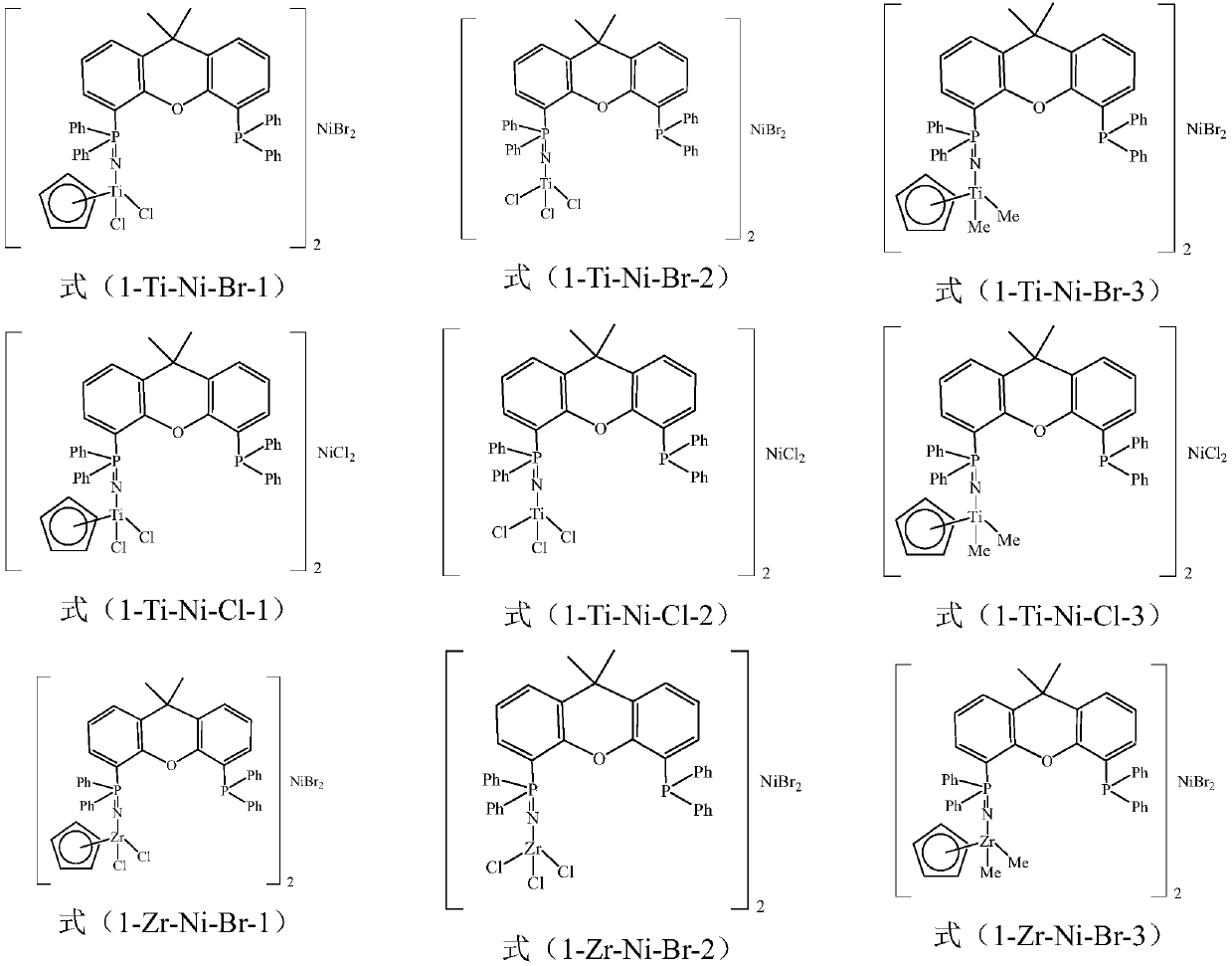

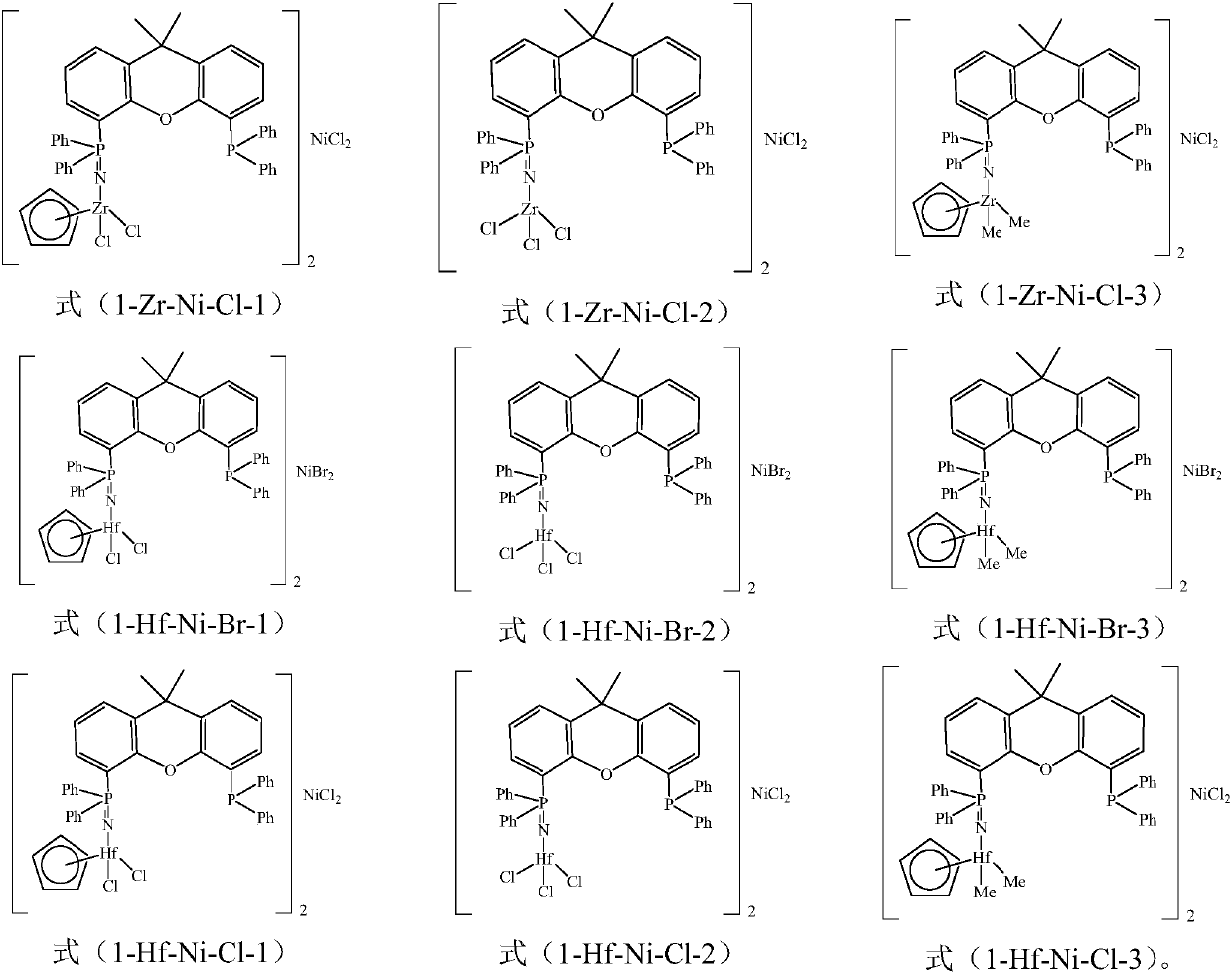

Heteronuclear bimetallic complexes, preparation method thereof and application of complexes in preparation of bimodal-distribution olefin polymers

A complex and bimetallic technology, applied in the direction of organic chemistry, can solve the problems of cumbersome operation, time-consuming, low efficiency, etc., and achieve the effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

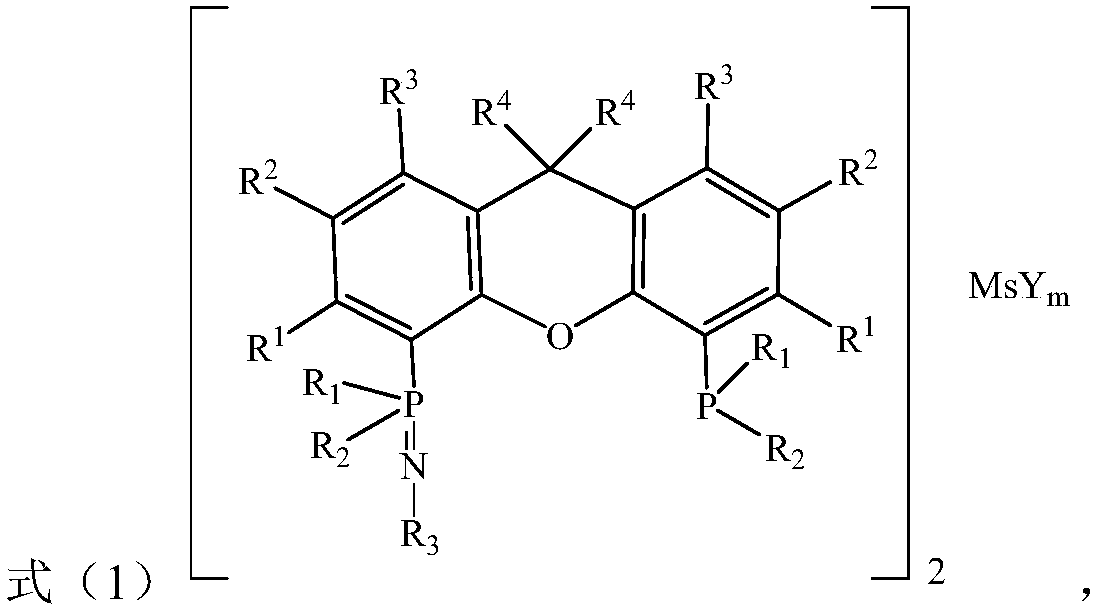

[0224] The second aspect of the present invention provides a method for preparing the above-mentioned heteronuclear bimetallic complex, the method comprising:

[0225] (1) carrying out the first substitution reaction with the compound shown in formula (4) and organolithium reagent;

[0226] (2) carrying out the second substitution reaction with the product of the first substitution reaction and the compound shown in formula (a), to obtain the compound shown in formula (3);

[0227] (3) performing Staudinger reaction on the compound shown in formula (3) and the azidosilane compound shown in formula (b), to obtain the compound shown in formula (2);

[0228] (4) carry out the third substitution reaction with the compound shown in formula (2) and the compound shown in formula (c), obtain the compound shown in formula (1');

[0229] Optionally, in the case where at least one of the n Xs in the compound represented by the formula (1') obtained in step (4) is a halogen, the method f...

Embodiment 1

[0364] This example is used to illustrate the heteronuclear bimetallic complex of the present invention and its preparation method.

[0365]

[0366] Prepare according to the above reaction formula, specifically:

[0367] (1) Dilute 9,9-dimethylxanthene (0.02mol) and tetramethylethylenediamine (TMEDA) (42mmol) in hexane (50mL), and add dropwise at -78°C -BuLi (42mmol) in hexane solution (addition completed within about 5min), reacted for 1h, then raised to room temperature (about 25°C), and continued stirring for 16h;

[0368] (2) Then add 15 mL of diphenylphosphine chloride (42 mmol) in n-hexane solution dropwise to the reaction system of step (1) in an ice-water bath (complete addition within about 5 min), and then continue at room temperature (about 25 ° C) ) under stirring reaction for 16h; the solvent was removed by rotary evaporation to obtain a light yellow viscous oil, which was washed with acetone and dried in vacuo to obtain 9.7g white powder, which was the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com