Method for arranging high-altitude thick weathering crust leaching type rare earth ore in-situ leaching liquid injection wells

A weathering crust leaching type and in-situ leaching technology, which is applied in the direction of improving process efficiency, can solve the problems of landslide geological disasters, large thickness of weathering crust ore body, and complex internal structure, so as to prevent landslide geological disasters and improve Rare earth leaching rate and the effect of improving rare earth recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

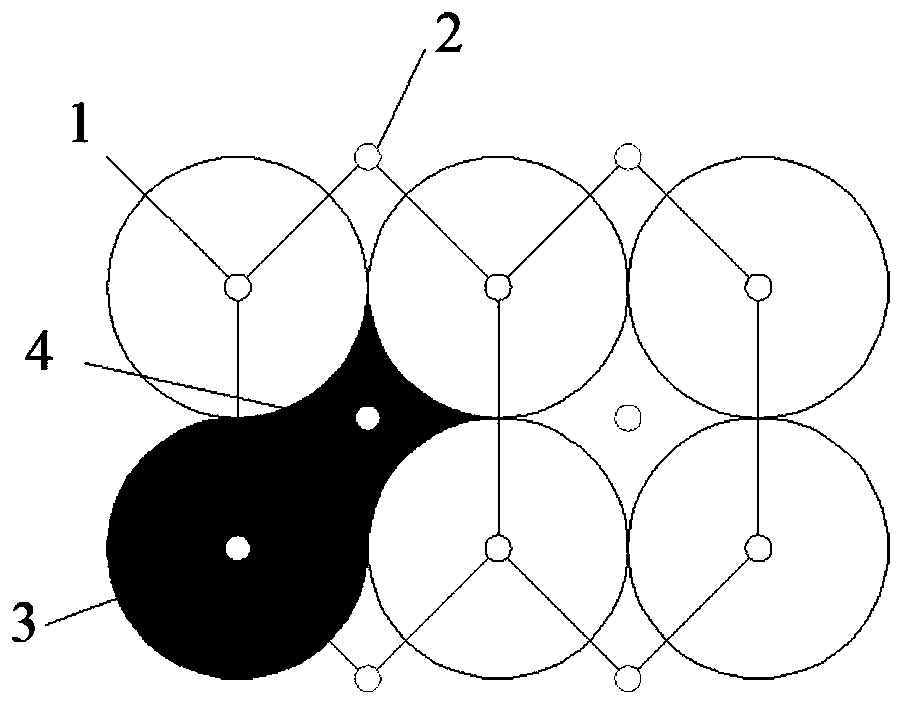

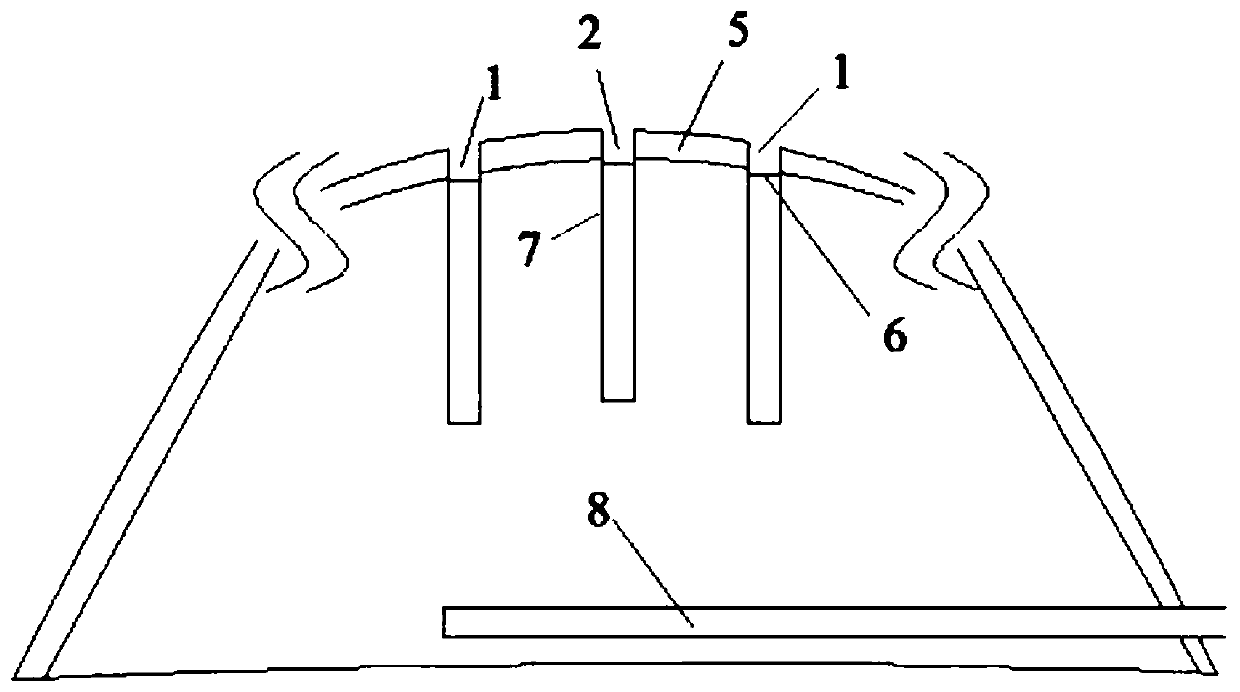

[0041] see Figure 1-2 , a high-altitude thick weathered crust rare earth mine in southern Yunnan, the rare earth composition is medium yttrium rich in europium, and the average grade of rare earth is RE 2 o 3 0.082%. The mine adopts the in-situ leaching process to recover rare earths, and the specific steps are as follows:

[0042] Along the surface of the ore body, the liquid injection wells are arranged according to the grid pattern, with a spacing of 2×2m, and another liquid injection well is set in the center of each grid, so that the distance between the grid point liquid injection wells 1, the The distance between the liquid injection wells 2 in the grid center is 2m, and the distance between the liquid injection well 1 at the grid point and the liquid injection well 2 in the grid center is 1.414m, forming a "plum blossom" liquid injection well system.

[0043] According to the coordinates of the spatial position of the liquid injection well, the liquid injection we...

Embodiment 2

[0052] see Figure 1-2 , a high-altitude thick weathered crust rare earth mine in southern Yunnan, the rare earth composition is medium yttrium rich in europium, and the average grade of rare earth is RE 2 o 3 0.091%. The mine adopts the in-situ leaching process to recover rare earths, and the specific steps are as follows:

[0053] The liquid injection wells are arranged along the surface of the ore body according to the grid pattern, with a spacing of 3×3m, and another liquid injection well is set in the center of each grid, so that the distance between the grid point liquid injection wells 1 and the grid center injection well The distance between the liquid wells 2 is 3m, and the distance between the grid point liquid injection well 1 and the grid center liquid injection well 2 is 1.732m, forming a "quincunx-shaped" liquid injection well liquid injection system.

[0054] According to the coordinates of the spatial position of the liquid injection well, the liquid injecti...

Embodiment 3

[0062] see Figure 1-2 , a high-altitude thick weathering crust rare earth mine in southern Yunnan, the rare earth composition is medium yttrium rich in europium, and the average grade of rare earth is RE2O30.086%. The mine adopts the in-situ leaching process to recover rare earths, and the specific steps are as follows:

[0063] The liquid injection wells are arranged along the surface of the ore body according to the grid pattern, with a spacing of 2.5×2.5m, and another liquid injection well is set at the center of each grid, so that the distance between the grid point liquid injection wells 1 and the grid center The distance between the liquid injection wells 2 is 2.5m, and the distance between the grid point liquid injection well 1 and the grid center liquid injection well 2 is 1.581m, forming a "quincunx-shaped" liquid injection well liquid injection system.

[0064] According to the spatial position coordinates of the liquid injection well, the liquid injection well is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com