OLED for improving efficiency stability based on anode modification layer

An anode modification layer and stability technology, applied in the field of organic electroluminescent devices, can solve the problems of lowering the energy barrier of ITO and NPB, increasing the manufacturing cost and process difficulty, and unstable device efficiency, so as to improve the unstable efficiency and improve the efficiency of the device. Efficiency stability, good feasibility and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

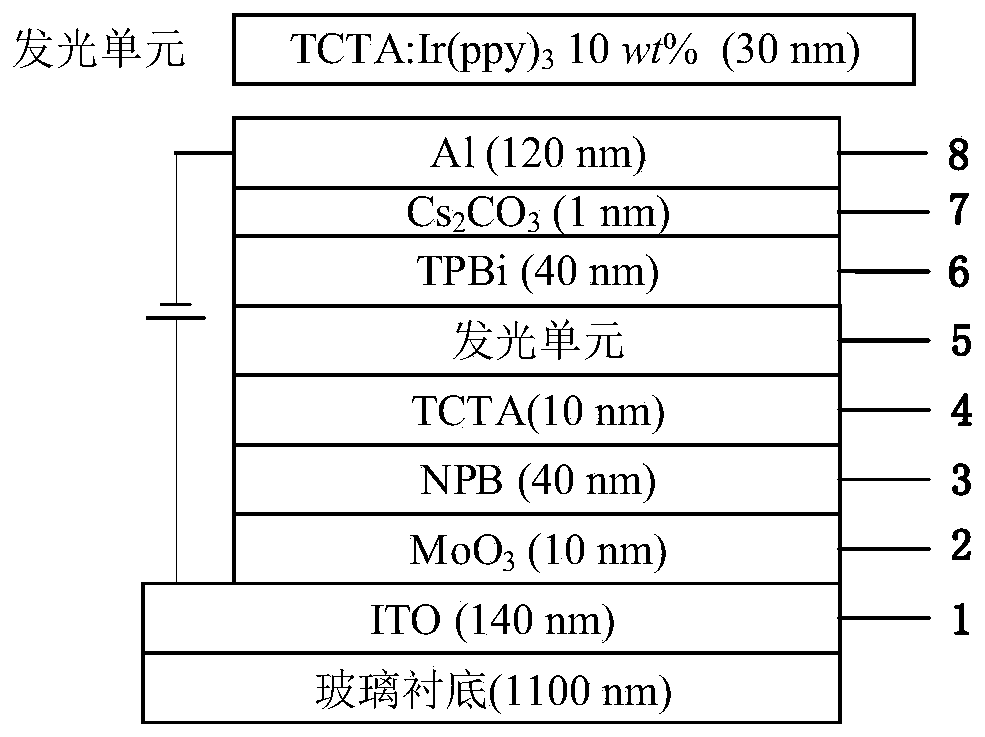

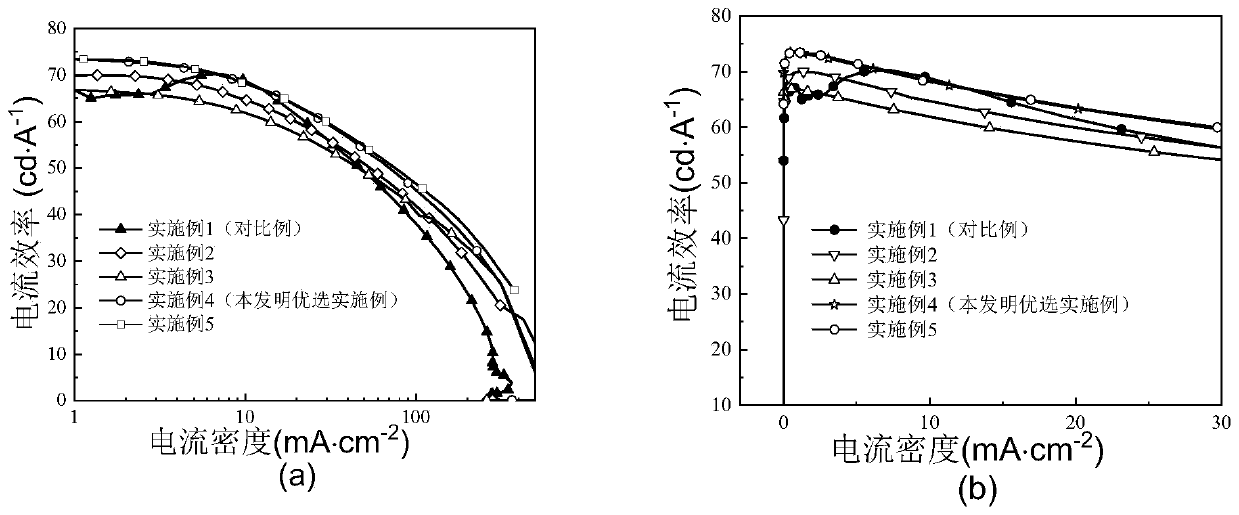

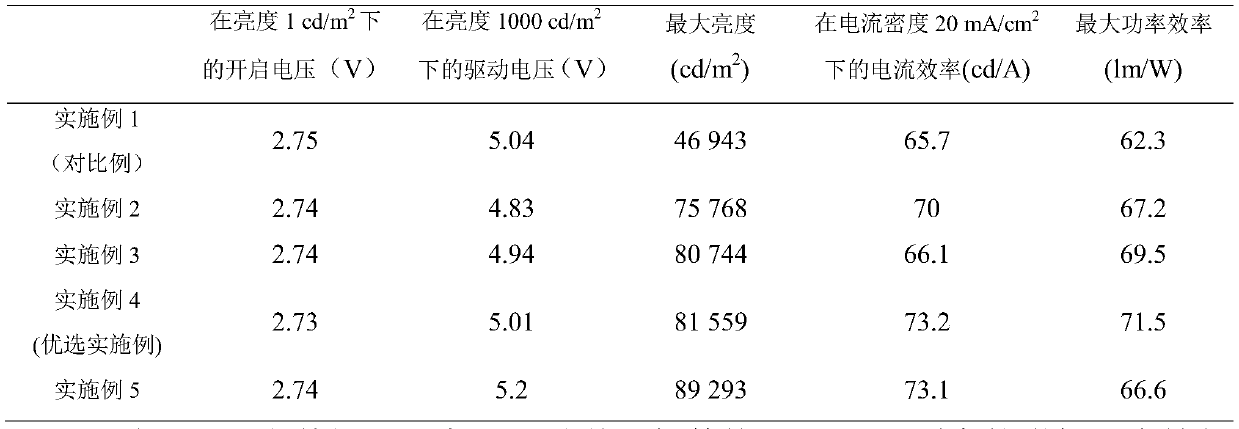

[0022] Example 1 (comparative example):

[0023] An organic electroluminescence device comprises an anode, a hole injection layer, a hole transport layer, a light-emitting unit, an electron transport layer, an electron injection layer and a cathode arranged in sequence. The organic electroluminescence device structure of this embodiment is Glass (1100nm) / ITO (140nm) / NPB (40nm) / TCTA (10nm) / TCTA:Ir (ppy) 3 (10wt%, 10nm) / TPBi(40nm) / Cs 2 CO 3 (1nm) / Al(120nm). The lighting voltage of the device in this embodiment is 2.75V, and the maximum brightness is 46 943cd / m 2 , the maximum power efficiency is 62.3lm / W, at a current density of 20mA / cm 2 The current efficiency under is 65.7cd / A.

example 2

[0025] An organic electroluminescence device comprises an anode, a hole injection layer, a hole transport layer, a light-emitting unit, an electron transport layer, an electron injection layer and a cathode arranged in sequence. The structure of the organic electroluminescent device in this embodiment is Glass (1100nm) / ITO (140nm) / MoO 3 (1nm) / NPB(40nm) / TCTA(10nm) / TCTA:Ir(ppy) 3 (10wt%, 10nm) / TPBi(40nm) / Cs 2 CO 3 (1nm) / Al(120nm). The lighting voltage of the device in this embodiment is 2.74V, and the maximum brightness is 75 768cd / m 2 , the maximum power efficiency is 67.2lm / W, at a current density of 20mA / cm 2 The current efficiency under is 70cd / A.

example 3

[0027] An organic electroluminescence device comprises an anode, a hole injection layer, a hole transport layer, a light-emitting unit, an electron transport layer, an electron injection layer and a cathode arranged in sequence. The structure of the organic electroluminescent device in this embodiment is Glass (1100nm) / ITO (140nm) / MoO 3 (5nm) / NPB(40nm) / TCTA(10nm) / TCTA:Ir(ppy) 3 (10wt%, 10nm) / TPBi(40nm) / Cs 2 CO 3 (1nm) / Al(120nm). The lighting voltage of the device in this embodiment is 2.74V, and the maximum brightness is 80 744cd / m 2 , the maximum power efficiency is 69.5lm / W, at a current density of 20mA / cm 2 The current efficiency under the condition is 66.1cd / A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Brightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com