Method and device for heating to-be-heated object

A technology of heated objects and heating methods, applied in the direction of combustion methods, burner control devices, lighting and heating equipment, etc., can solve the problems of long process time and decreased manufacturing efficiency, and achieve the reduction of carbon dioxide and nitrogen oxides and efficient drying and heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

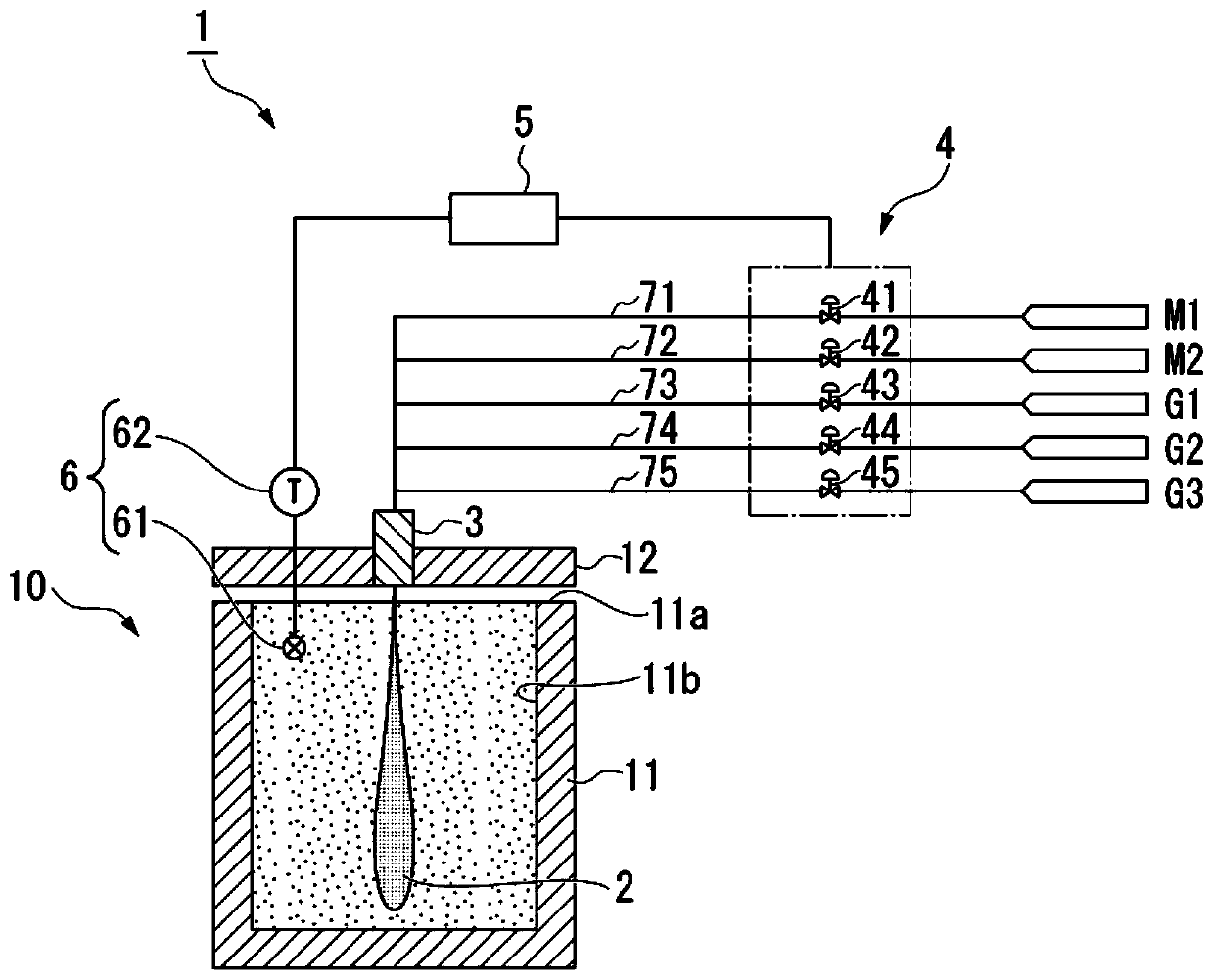

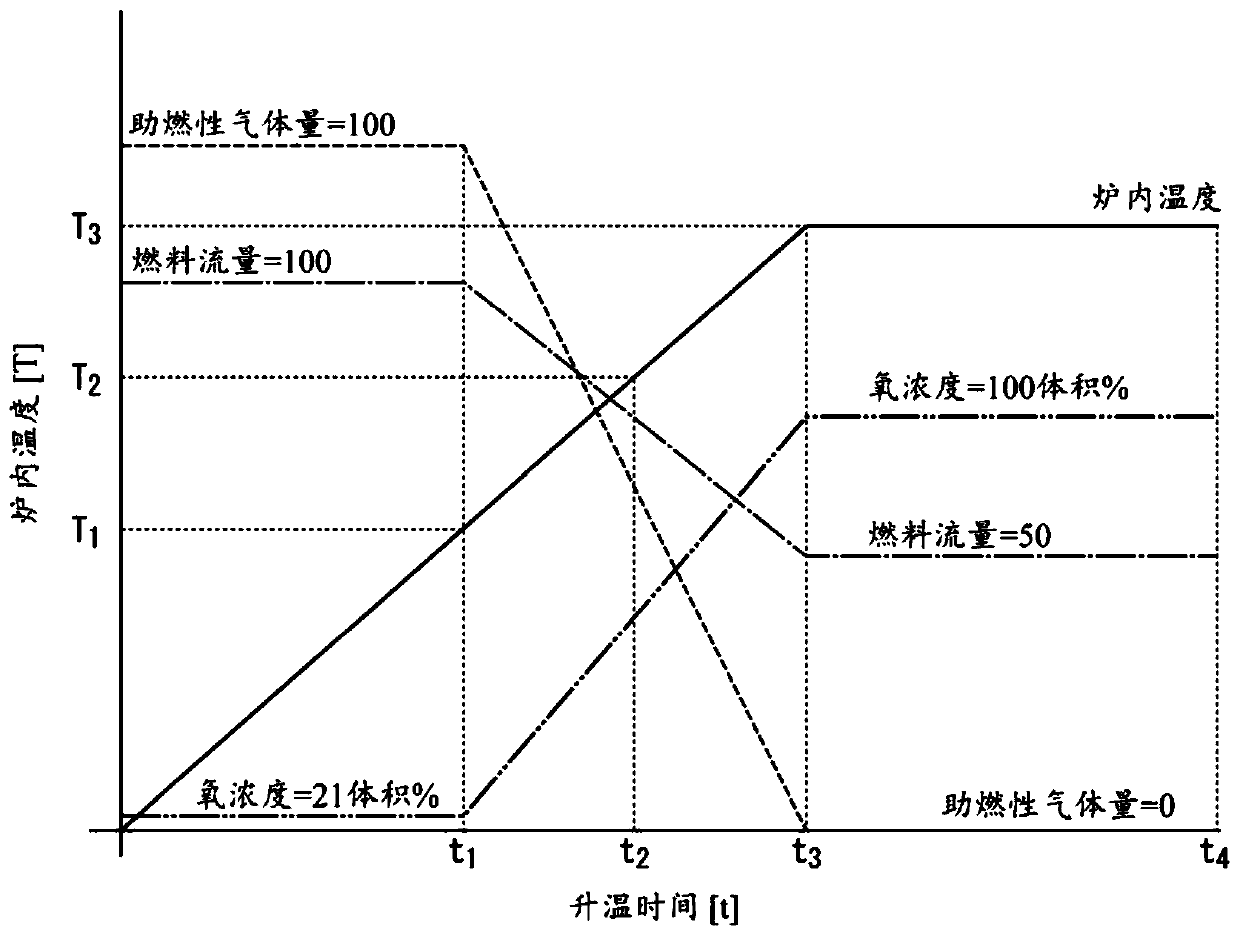

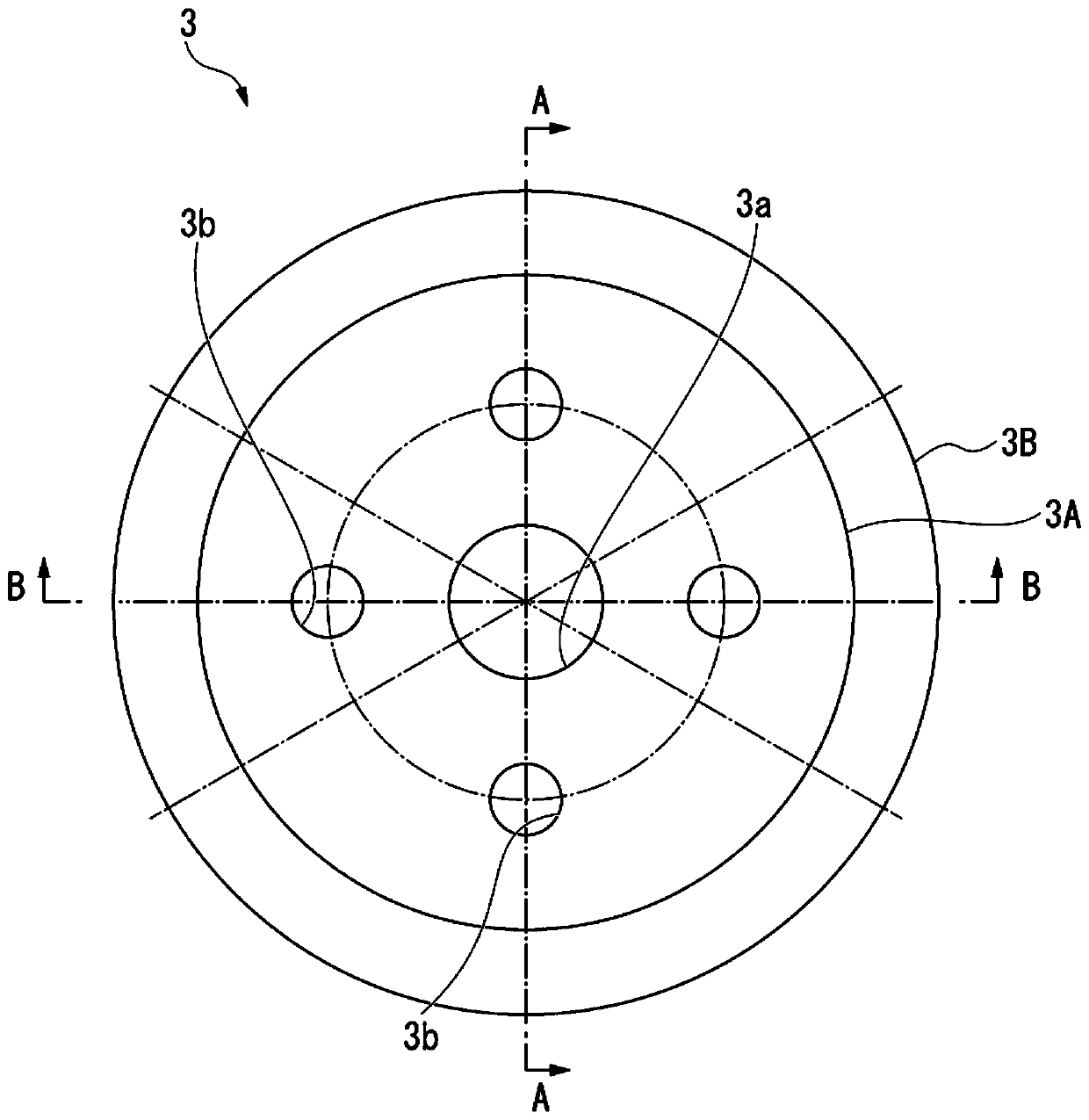

[0036] Below, refer to the appropriate Figure 1 to Figure 6 The method and apparatus for heating an object to be heated according to one embodiment of the present invention will be described. In addition, in order to facilitate the understanding of features, in the drawings used in the following description, characteristic parts are sometimes enlarged for convenience, and the dimensional ratios of each component are not necessarily the same as the actual ones. In addition, the materials etc. which are illustrated in the following description are an example, and this invention is not limited to these materials, In the range which does not change the gist of this invention, this invention can be implemented with a proper change.

[0037] The heating method and heating device of the object to be heated according to the present invention can be applied, for example, to preheating a molten metal ladle or a tundish used for transporting molten iron or steel in an ironmaking or stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com