Mineral fiber treatment system and treatment method thereof

A mineral fiber and processing system technology, applied in chemical instruments and methods, separating solids from solids with airflow, solid separation, etc., can solve the problems of reducing the quality of mineral fibers, loss of mineral fibers, low productivity, etc., and achieve improvement Stirring effect, increase the overlapping area, and improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

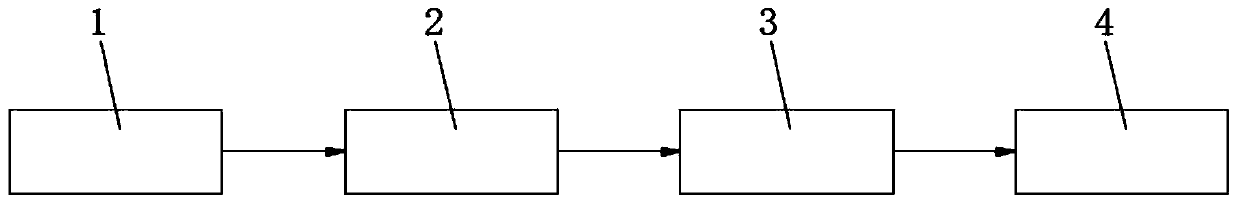

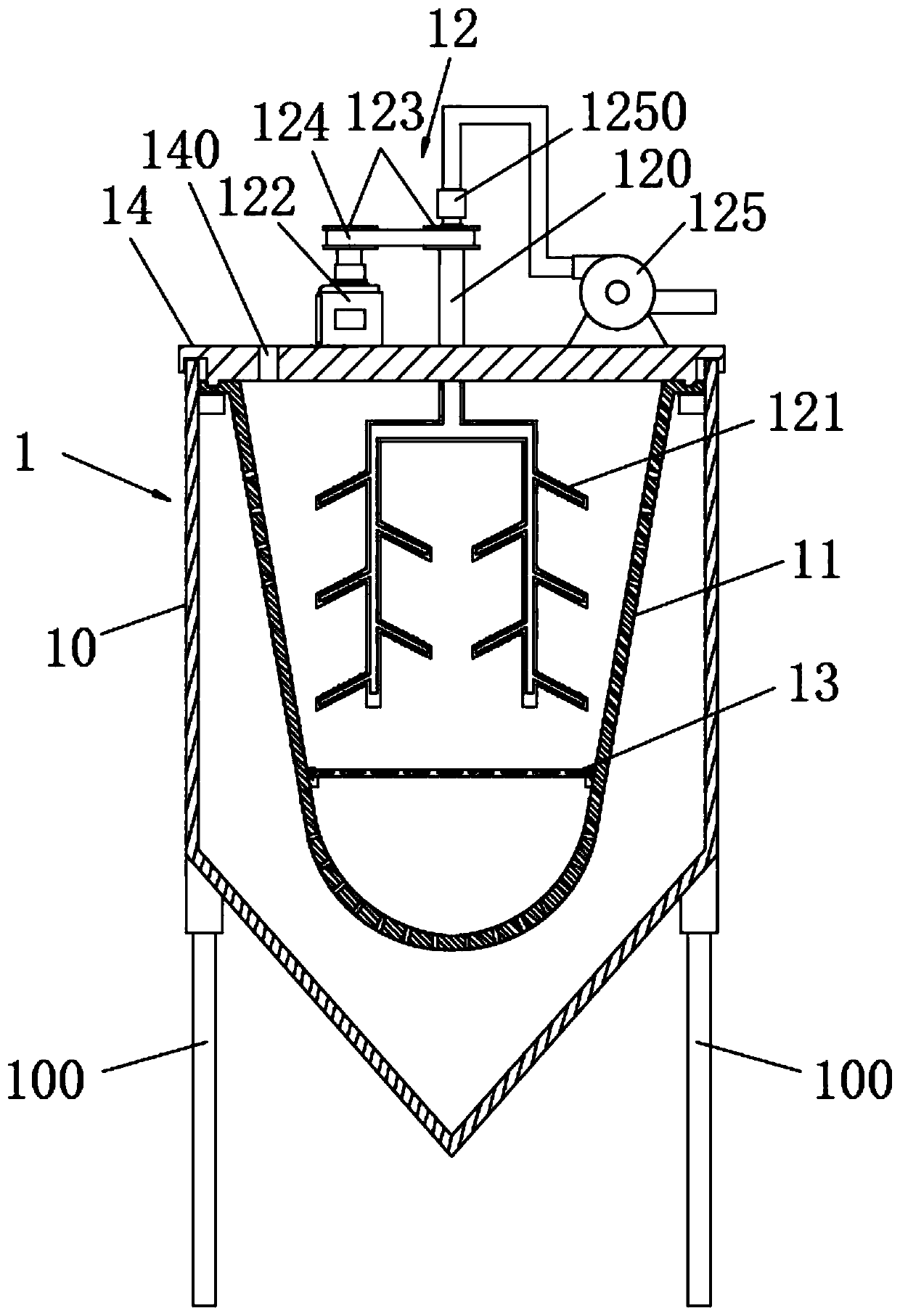

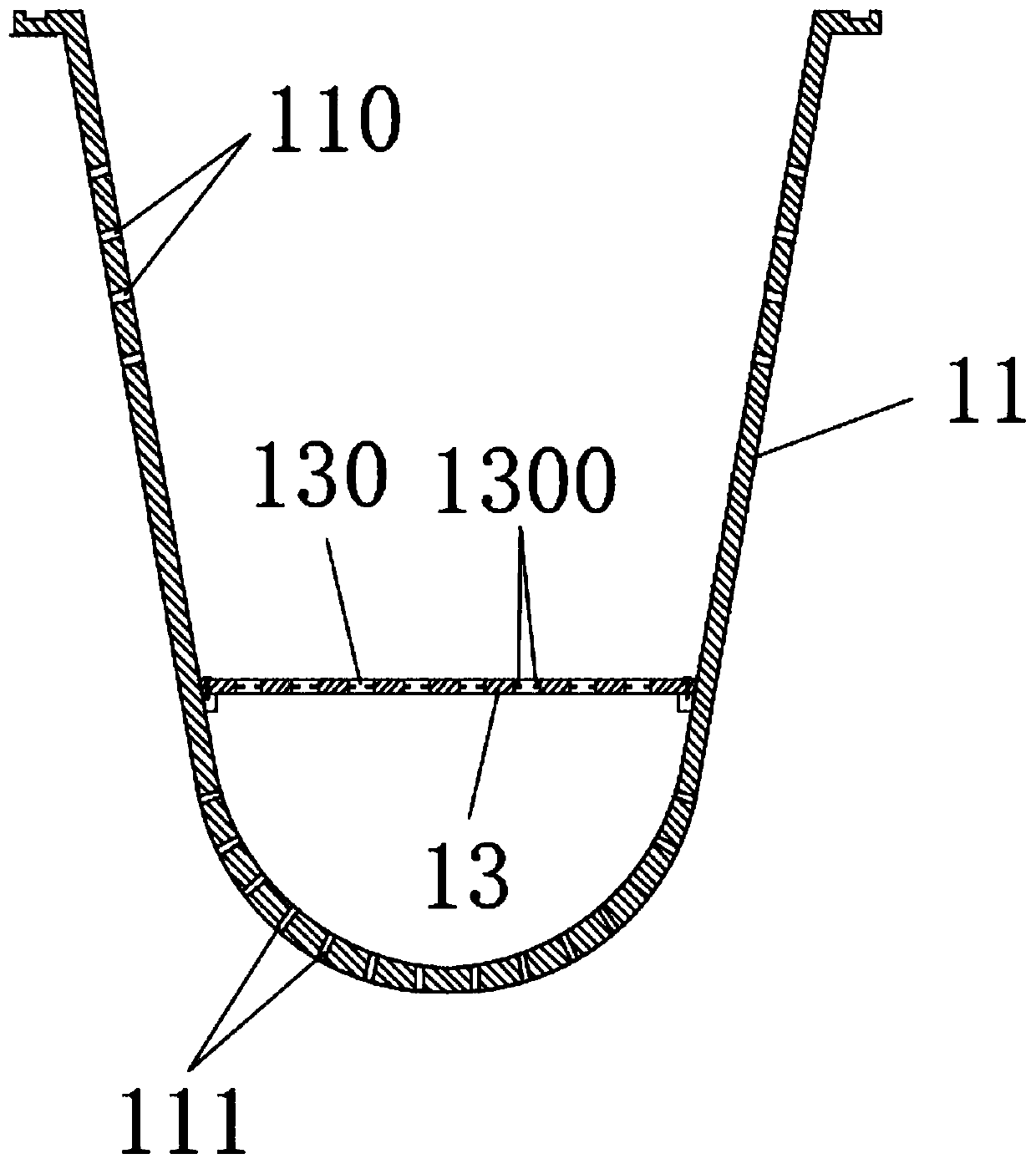

[0037] Such as Figure 1 to Figure 9 As shown, a mineral fiber processing system includes a deslagging device 1, a chopping device 2, a drying device 3, and a classification device, which are sequentially arranged and used to remove, chop, dry, and screen mineral fibers containing ball slag. Device 4; the chopped device 2 adopts the existing mineral fiber chopped device 2; the slag removing device 1 includes a soaking cylinder 10 containing soaking liquid, a cone-shaped slag removing basket 11 with an upward opening, and a slag removing device A mixer 12; a plurality of supporting feet 100 are fixed at the lower end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com