Low-cost black FDM printing filament prepared by utilizing recycled tobacco film masterbatch as well as preparation method and application of printing filament

A printing filament, low-cost technology, applied in the field of materials, can solve the problems of expensive PLA type 3D printing materials, increase production time and cost, increase processing links, etc., to achieve uniform coloring effect, good coloring effect, and coloring effect without color cast Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the low-cost black FDM printing wire rod prepared by recycling cigarette film masterbatch according to the present invention comprises the following steps:

[0040] A. Dry the raw material recycled tobacco film masterbatch and polylactic acid (PLA) in a vacuum drying oven for 24 hours for later use;

[0041] B. Weigh the dried recycled cigarette film masterbatch and polylactic acid, compatibilizer, additives, and white oil according to the formula ratio, add them to the high-mixer and heat to 90~110°C, and stir at a speed of 4000~6000rpm for 30 ~50min to get material a;

[0042] C. Extrude material a through a twin-screw extruder, then cool to room temperature and send it to a pelletizer to cut to obtain material b;

[0043] D. Extrude material b through a die in a twin-screw extruder to obtain the target product.

[0044] The temperature of the twin-screw extruder described in step C is 150-210nb°C, and the rotation speed is 50-70rpm.

[00...

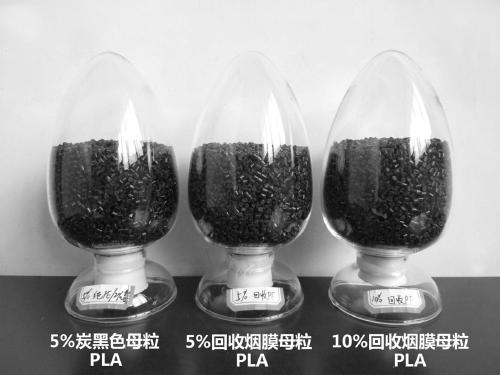

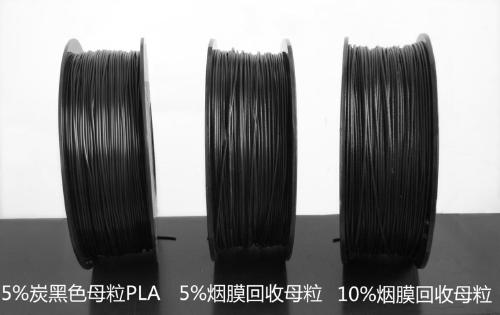

Embodiment 1

[0048] (1) The weight percentage formula is as follows:

[0049] Recycled tobacco film masterbatch 5

[0050] PLA 95

[0051] PE-g-MAH 2

[0052] DA-310ST 0.5

[0053] White oil 0.5

[0054] (2) Preparation method:

[0055] A. Place the recovered cigarette film masterbatch and PLA in a vacuum drying oven to dry;

[0056] B. According to the weight percentage formula, weigh the dried recycled cigarette film masterbatch, PLA, PE-g-MAH, P990, white oil;

[0057] C. Place the weighed components in a high-speed kneader, keep the speed at 2000 rpm, and stir at high speed for 20 minutes;

[0058] D. Add the uniformly mixed recycled cigarette film masterbatch, PLA, PE-g-MAH, P990, and white oil to the feed port of the twin-screw extruder. The temperature of the twin-screw extruder is 150-210°C, and the rotation speed is 70rpm; The raw material extruded from the screw is sent to the pelletizer after being cooled and cut into pellets, such as figure 1 As shown, dry and set aside...

Embodiment 2

[0063] (1) weight percentage formula is as follows:

[0064] Recycled tobacco film masterbatch 10

[0065] PLA90

[0066] POE-g-GMA 5

[0067] DA-310ST 1

[0068] white oil 1

[0069] (2) Preparation method:

[0070] A. Place the recovered cigarette film masterbatch and PLA in a vacuum drying oven to dry;

[0071] B. According to the weight percentage formula, weigh the dried recycled cigarette film masterbatch, PLA, POE-g-GMA, DA-310ST, white oil;

[0072] C. Place the weighed components in a high-speed kneader, keep the speed at 1000-6000 rpm, and stir at high speed for 5-30 minutes;

[0073] D. Add the uniformly mixed recycled cigarette film masterbatch, PLA, POE-g-GMA, DA-310ST, and white oil to the feeding port of the twin-screw extruder. The temperature of the twin-screw extruder is 150-210°C, and the speed is 150rpm; the raw material extruded from the screw is cooled and sent to the pelletizer to be cut into pellets, such as figure 1 As shown, dry and set aside;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com