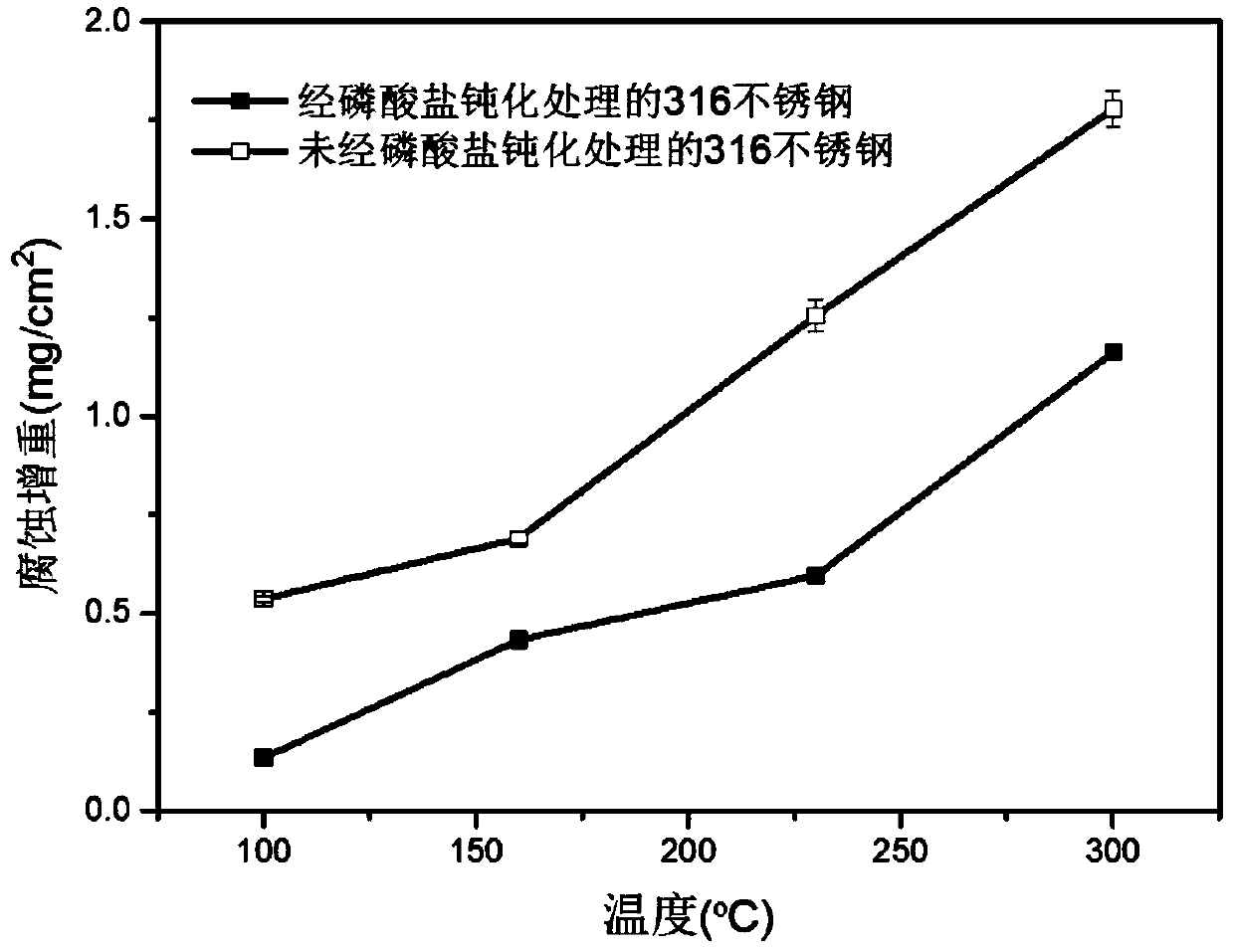

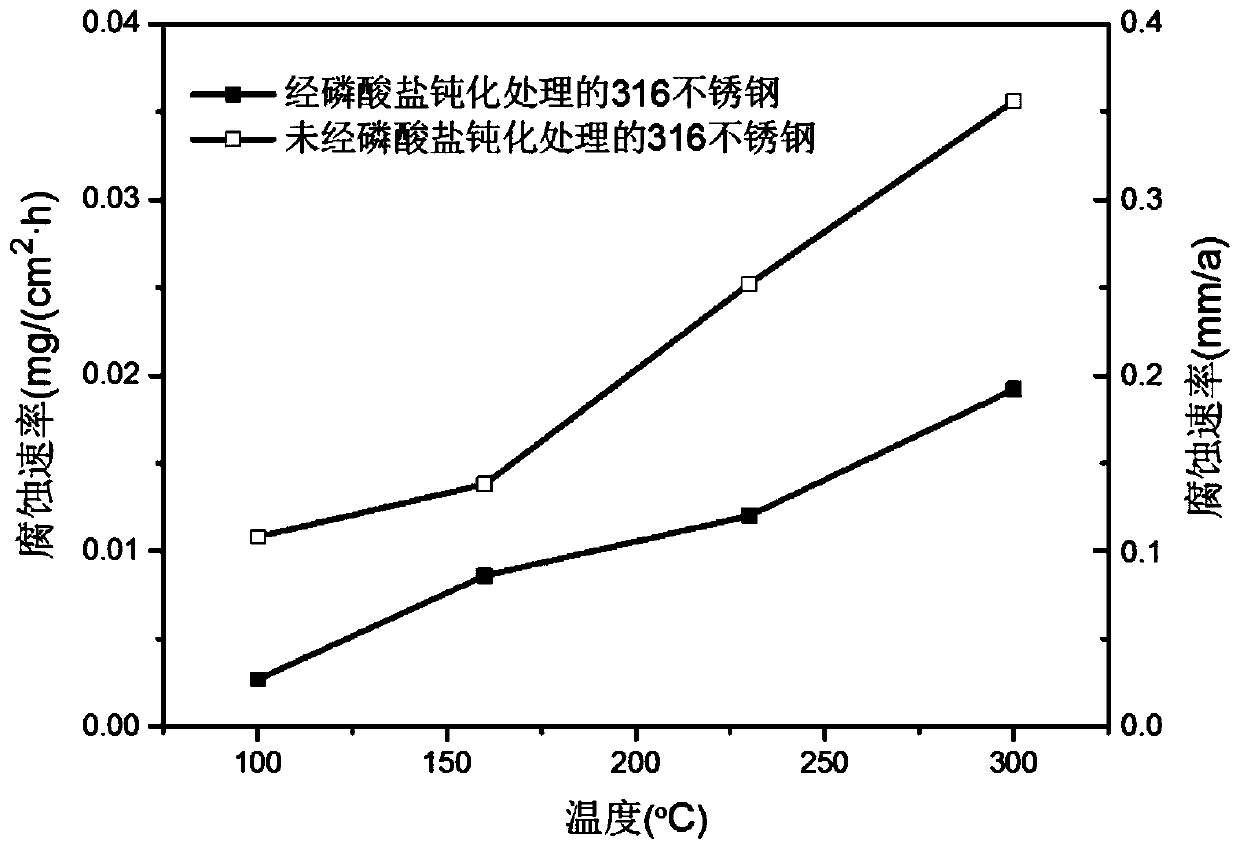

Phosphate passivation treatment method resistant to chlorine-containing subcritical water corrosion

A passivation treatment and subcritical water technology, applied in the coating process of metal materials, etc., can solve problems such as subcritical area corrosion, and achieve the effect of mild treatment process conditions, good corrosion resistance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The reagent used for passivation treatment is 1500mg / L Na 3 PO 4 solution, the passivation temperature is 450°C, the passivation pressure is 25MPa, and the passivation time is 50h.

[0027] Select 316 stainless steel as the base alloy, process the alloy into a cuboid sample coupon of 10mm×10mm×7mm, use metallographic sandpaper and diamond polishing agent with a particle size of 1 μm to mechanically polish all the outer surfaces of the sample, and use the sandpaper in order of 400 Mesh, 600 mesh, 800 mesh, 1200 mesh, 1600 mesh, the surface of the polished sample should be a smooth mirror surface without obvious flaws or scratches, then put the sample in acetone solution for ultrasonic cleaning for 20 minutes and then dry it for later use .

[0028] Passivate the above sample in a high-temperature and high-pressure reactor, and add 1500 mg / L of Na in the reactor. 3 PO 4 Solution, hang the spare sample in the center of the reactor with a thin silver wire and avoid cont...

Embodiment 2

[0032] The reagent used for passivation treatment is 1800mg / L Na 3 PO 4 solution, the passivation temperature is 430°C, the passivation pressure is 24MPa, and the passivation time is 150h.

[0033]Select 316 stainless steel as the base alloy, process the alloy into a cuboid sample coupon of 10mm×10mm×7mm, use metallographic sandpaper and diamond polishing agent with a particle size of 1 μm to mechanically polish all the outer surfaces of the sample, and use the sandpaper in order of 400 Mesh, 600 mesh, 800 mesh, 1200 mesh, 1600 mesh, the surface of the polished sample should be a smooth mirror surface without obvious blemishes or scratches, then put the sample in acetone solution for ultrasonic cleaning for 25 minutes and then dry it for later use .

[0034] Passivate the above sample in a high-temperature and high-pressure reactor, and add 1800 mg / L of Na in the reactor. 3 PO 4 Solution, hang the spare sample in the center of the reactor with a thin silver wire to avoid c...

Embodiment 3

[0037] The reagent used for passivation treatment is 2000mg / L Na 3 PO 4 solution, the passivation temperature is 400°C, the passivation pressure is 23MPa, and the passivation time is 500h.

[0038] Select 316 stainless steel as the base alloy, process the alloy into a cuboid sample coupon of 10mm×10mm×7mm, use metallographic sandpaper and diamond polishing agent with a particle size of 1 μm to mechanically polish all the outer surfaces of the sample, and use the sandpaper in order of 400 Mesh, 600 mesh, 800 mesh, 1200 mesh, 1600 mesh, the surface of the polished sample should be a smooth mirror surface without obvious flaws or scratches, then put the sample in acetone solution for ultrasonic cleaning for 30 minutes and then dry it for later use .

[0039] Passivate the above sample in a high-temperature and high-pressure reactor, and add 2000 mg / L of Na in the reactor. 3 PO 4 Solution, hang the spare sample in the center of the reactor with a thin silver wire and avoid con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com