Vertical sensitive magnetic sensor closed-loop on-chip in-place feedback device

A magnetic sensor and feedback device technology, applied in the field of magnetic sensors, can solve the problems of poor open-loop design linearity, low measurement accuracy, and high packaging cost, and achieve the effects of improving output linearity, improving measurement accuracy, and expanding measurement bandwidth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

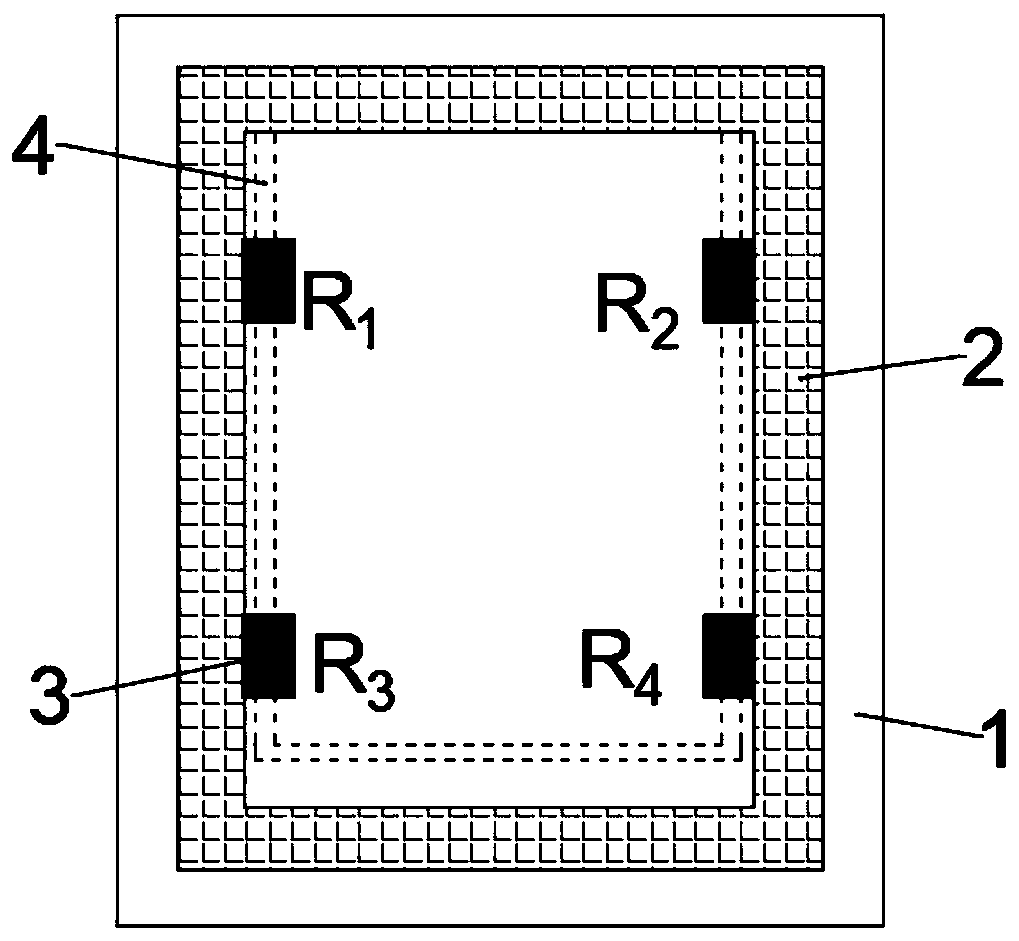

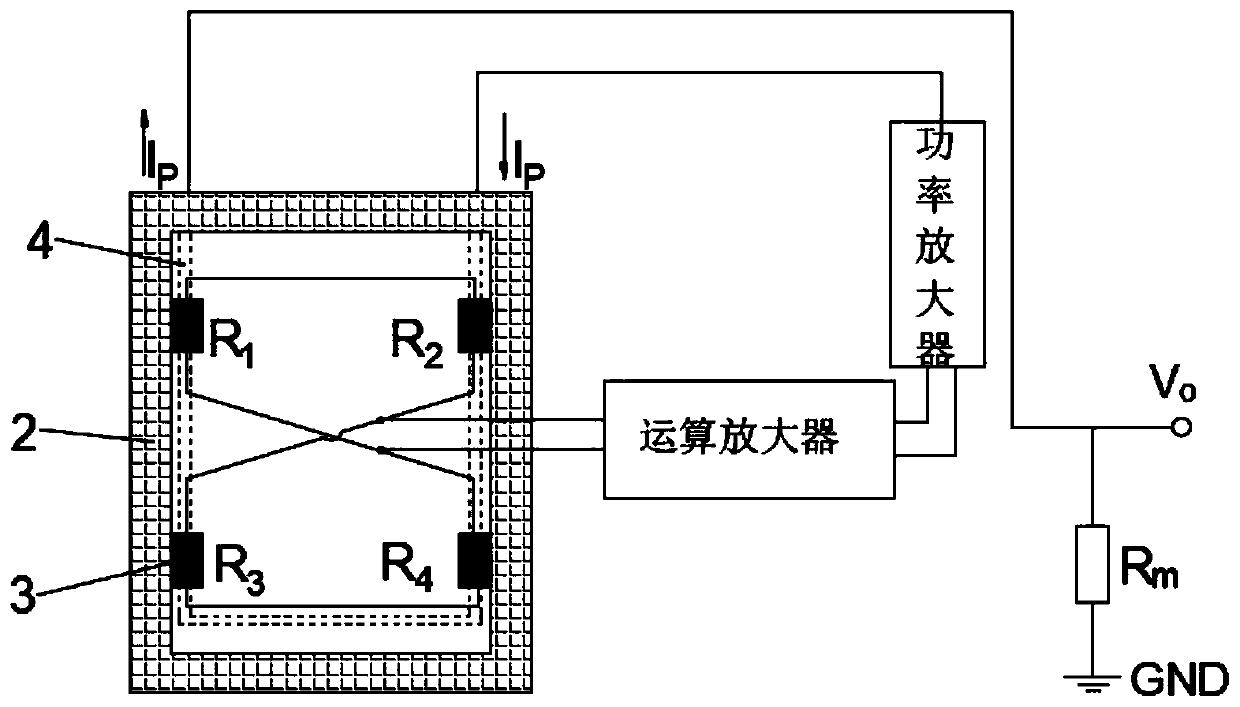

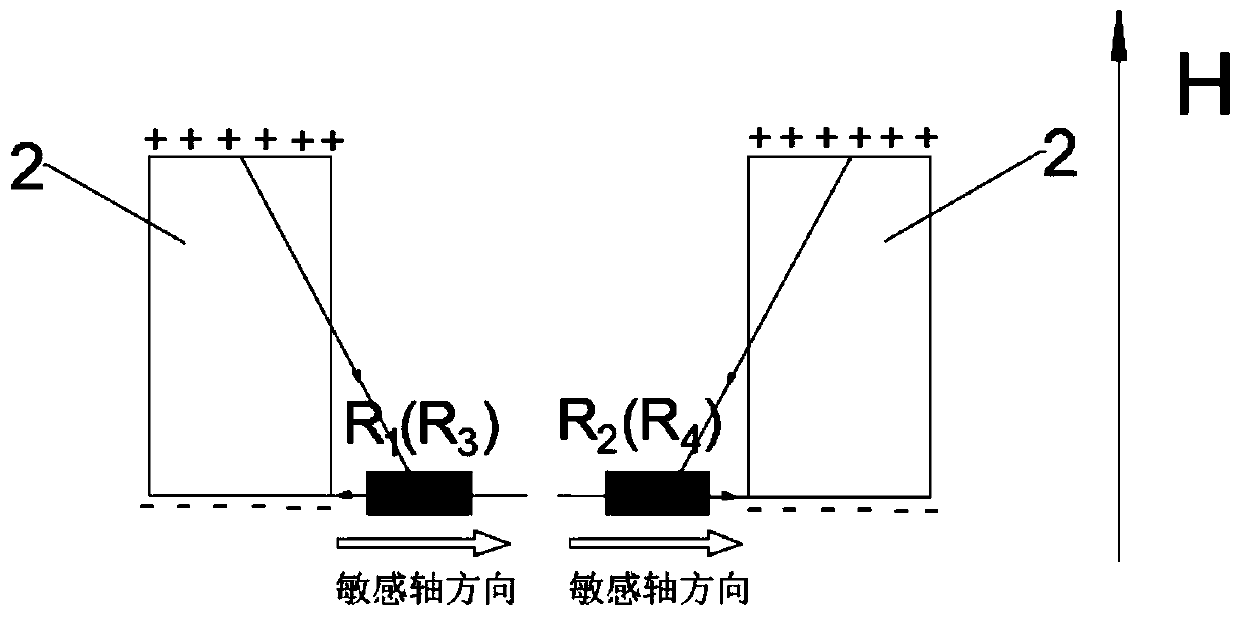

[0020] Such as figure 1 with 2 As shown, the present invention provides a closed-loop on-core on-core feedback device with vertical sensitivity, which includes a silicon-based substrate 1, a flux guide 2, four identical magnetoresistors 3, a signal feedback coil 4, and an operation Amplifiers and Power Amplifiers.

[0021] The operational amplifier selected in this embodiment is either AD620 or AD623 of ADI Company. The function of the operational amplifier is to amplify the output voltage value of the sensor, because the voltage generated by the sensor chip belongs to the micro voltage and is generally in the millivolt level. It is convenient for subsequent processing. The magnification of the operational amplifier can be magnified up to 1000 times, and adjusting the appropriate magnification is convenient for signal analysis, processing and measurement.

[0022] In this embodiment, the power amplifier can choose the LM3886 power amplifier of National Semiconductor of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com