Preparation method and application of nano flower-like Ni-NiMoO4-Ni3S2 micro-nano electrode material

A nano-electrode and nano-composite material technology, applied in nano-composite material preparation and supercapacitor application, micro-field, can solve the problems of unsuitable synthesis of metal oxide or sulfide core-shell nano-heterostructure, complicated operation and high cost, reaching Great commercial prospects, improved electrochemical performance, reduced use of binders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

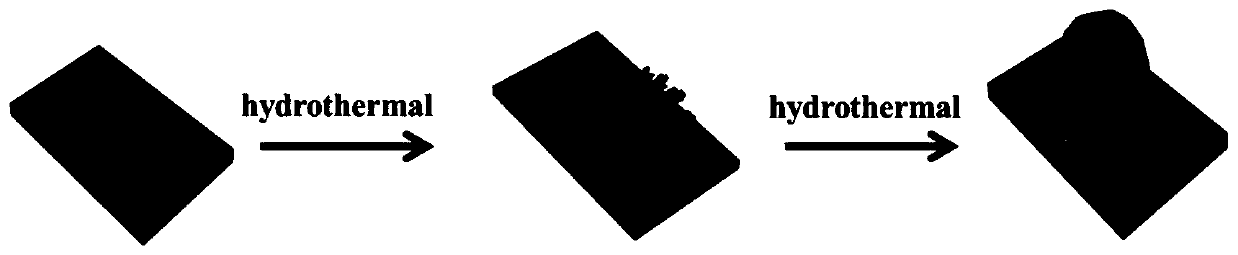

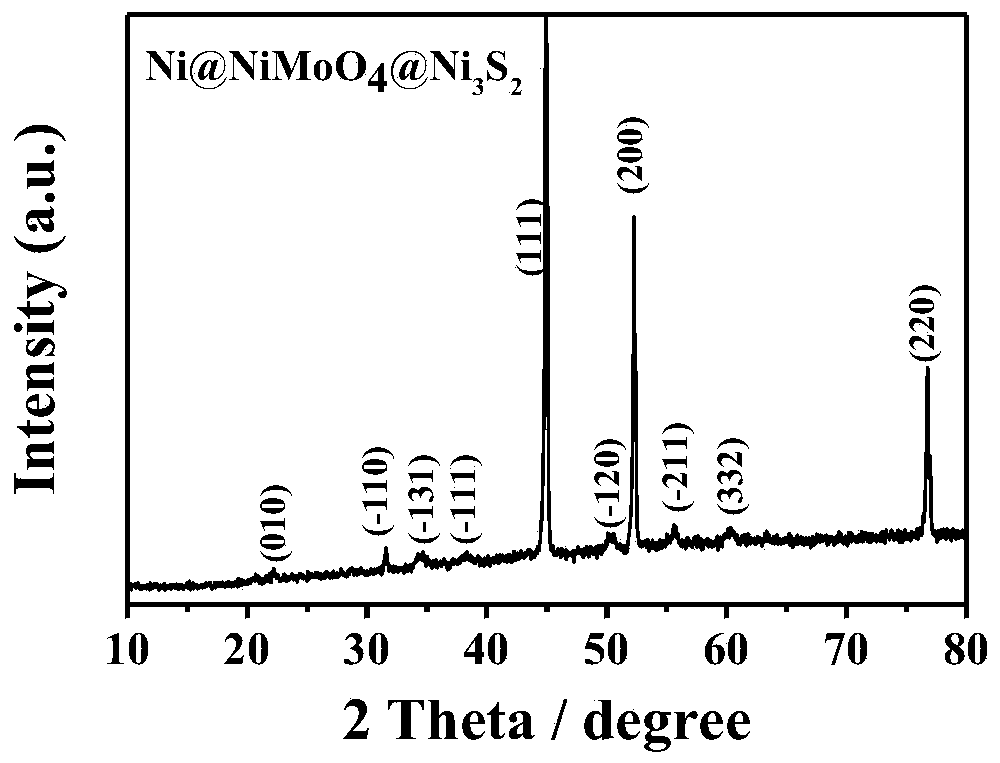

[0034] A nanoflower-like structure Ni@NiMoO 4 @Ni 3 S 2 Micro-nanocomposite, in situ growth of NiMoO on nickel foam via a simple and low-cost hydrothermal method and heat treatment process 4 array of nanowires. Ni was then hydrothermally 3 S 2 Nanosheets supported on Ni@NiMoO 4 Nanoflower-like Ni@NiMoO formed on the nanowire skeleton 4 @Ni 3 S 2 Micro and nanocomposites.

[0035] The nano-flower structure Ni@NiMoO described in the present invention 4 @Ni 3 S 2 The preparation method of micro-nanocomposite material, comprises the following steps: (1) nickel foam load NiMoO 4 The preparation of the nanowires is as follows: the nickel foam is cut into 3×2.5cm 2 , respectively, with 1M NaOH, 1M HCl, deionized water and absolute ethanol for 15 minutes until the nickel foam is neutral. Then place it in a vacuum oven and dry for 12 hours. Put 211mg of sodium molybdate and 0.26g of nickel nitrate in a 50mL beaker, add 25mL of deionized water and 5mL of ethylene glycol, ...

Embodiment 2

[0043] A nanoflower-like structure Ni@NiMoO 4 @Ni 3 S 2 Micro-nanocomposite material, characterized by in-situ growth of NiMoO on nickel foam by simple and low-cost hydrothermal method and heat treatment process 4 array of nanowires. Ni was then hydrothermally 3 S 2 Nanosheets supported on Ni@NiMoO 4 On the nanowire skeleton, a nanoflower-like structure Ni@NiMoO is formed 4 @Ni 3 S 2 Micro and nanocomposites.

[0044] The nanoflower-like structure Ni@NiMoO described in this example 4 @Ni 3 S 2 The preparation method of the micro-nano composite material is as in Example 1 except that the hydrothermal time of step (1) is adjusted to 6h, and the hydrothermal time of step (2) is changed to 4h.

[0045] The nano flower structure Ni@NiMoO described in this example 4 @Ni 3 S 2The application of the preparation method of the micro-nano composite material is the same as that in Example 1.

Embodiment 3

[0047] A nanoflower-like structure Ni@NiMoO 4 @Ni 3 S 2 Micro-nanocomposite material, characterized by in-situ growth of NiMoO on nickel foam by simple and low-cost hydrothermal method and heat treatment process 4 array of nanowires. Ni was then hydrothermally 3 S 2 Nanosheets supported on Ni@NiMoO 4 On the nanowire skeleton, a nanoflower-like structure Ni@NiMoO4@Ni is formed 3 S 2 Micro and nanocomposites.

[0048] The nanoflower-like structure Ni@NiMoO described in this example 4 @Ni 3 S 2 The preparation method of the micro-nano composite material is the same as the implementation example 1 except that the amount of nickel sulfate is changed to 100 mg in step (2).

[0049] The nano flower structure Ni@NiMoO described in this example 4 @Ni 3 S 2 The application of the preparation method of the micro-nano composite material is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com